From raw material extraction to landfill disposal, every phase of a product’s lifecycle carries an environmental cost. Due to ethical considerations and regulatory pressure, many manufacturers are transitioning away from wasteful production models. In response to climate concerns, they are replacing resource-heavy processes with a new commitment to sustainable design principles. PTC’s CAD platform, Creo, is a useful tool, designed to help engineers incorporate sustainability into their product development. Sustainable design with Creo empowers manufacturers to reduce environmental impact without compromising performance.

Material Selection and Recyclable Product Design

Up to 80% of a product’s carbon footprint is determined during the design phase, making the tools you use vital to sustainable design. Creo aids engineers by providing integrated material selection databases accounting for multiple factors. These include: carbon footprint, recyclability, and compliance with hazardous material regulations. Designers can weigh these material options against environmental, cost, and performance criteria. Then, they make their selection to maximize impact reduction.

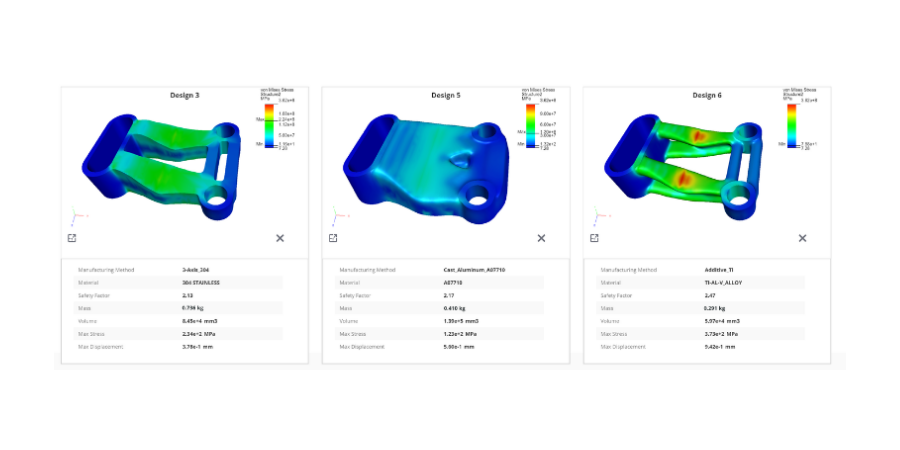

Generative design in Creo further advances sustainability by enabling dematerialization. Creo’s additive manufacturing capabilities allow designers to use lightweight lattice structures that use less material while still maintaining structural integrity. Lightweighting not only lowers operational energy consumption but also reduces emissions associated with sourcing, production, and transportation. In addition to this, Creo’s Generative Design Extension (GDX) supports simultaneous design studies. It can surface optimal material-efficient solutions that may otherwise go unexplored.

Model-Based Definition: Driving Traceability and Sustainable Design

Model-Based Definition (MBD) is transforming how organizations handle engineering and manufacturing by embedding rich, digital annotations directly into 3D models—eliminating the need for separate 2D drawings. This shift creates a single source of truth, significantly reducing engineering change orders by 41% and scrap by 47%. MBD also improves engineering productivity, supports streamlined manufacturing instructions, and enhances compliance with modern standards. As adoption rises, MBD is proving to be a key driver of cost savings, efficiency, and quality.

Environmental Impact Analysis

Creo’s partnership with aPriori, a data-driven software platform, adds another layer of sustainability insight. aPriori helps incorporate manufacturing impact data directly into the design phase. Engineers can simulate and evaluate energy use, waste generation, and CO₂ emissions across different manufacturing processes and materials. This proactive approach allows teams to make design trade-offs based on sustainability, cost, and manufacturability. Creo also supports modular xBOMs (extended Bill of Materials). A modular xBOM allows for the creation and management of multiple BOM representations tailored to your unique business processes. It can facilitate interchangeable component design, or replaceable parts designed to keep resources in use for as long as possible. This is otherwise known as a circular economy application as it minimizes waste and pollution. Interchangeable component design increases repair, reuse, and upgrade opportunities. Additionally, it reduces the total material consumption.

Simulation-Driven Sustainable Product Design

Simulation plays a critical role in enabling recyclable product design and sustainable development. Creo empowers design engineers to run real-time simulations early and often with tools like Creo Simulation Live (CSL) and Creo Ansys Simulation (CAS). These allow rapid iteration across thermal, structural, modal, and fluid analyses. They minimize reliance on physical prototypes and cut down on testing waste. By prioritizing simulation early (shifting simulation left), teams can identify performance issues and optimize for sustainability before products are manufactured. This reduces scrap, prevents costly redesigns, and ensures efficient use of materials.

Meeting Global Sustainability Standards with Confidence

While sustainability is about helping the planet, it’s also about remaining in compliance with regulatory standards. Creo equips manufacturers to align with evolving legal and regulatory frameworks, such as:

- CSRD (Corporate Sustainability Reporting Directive) – Strengthening environmental disclosure requirements in the EU

- IFRS S1 and S2 – Global sustainability disclosure standards incorporating climate-related risk

- RoHS, REACH, and WEEE – Regulating hazardous substances and electronic waste

Creo’s integrated model-based environment supports traceable product development and compliance reporting. With model-based definition (MBD), product manufacturing information is embedded directly into the 3D model, creating a single source of truth that supports digital product passports and environmental declarations.

Sustainable Design with Creo

As environmental challenges intensify, engineering teams must prioritize sustainable development. Creo’s rich ecosystem of tools positions it as a leader in enabling sustainability across the entire product development cycle. Its features work together to reduce design iteration cycles, prevent rework, and ensure that sustainability is embedded throughout the engineering process. By leveraging Creo, organizations can create more sustainable products at lower costs for a greener future. If you are interested in learning more about Creo for sustainability, contact our experts.