Getting products to market fast with minimal errors and lower costs across the pipeline can be challenging. However, it is the new standard for product developers. However, traditional product development cycles remain a major obstacle. Physical prototypes, lengthy testing phases, and last-minute design changes all prevent fast development. These issues can be avoided, though. CAD simulation, specifically Creo Simulation from PTC, provides an alternative. By leveraging simulation tools early and often in the design process, companies can reduce prototyping costs, accelerate product development, and improve design accuracy with CAD. Let’s explore how Creo allows organizations to produce innovative, quality products.

Creo’s Simulation Capabilities

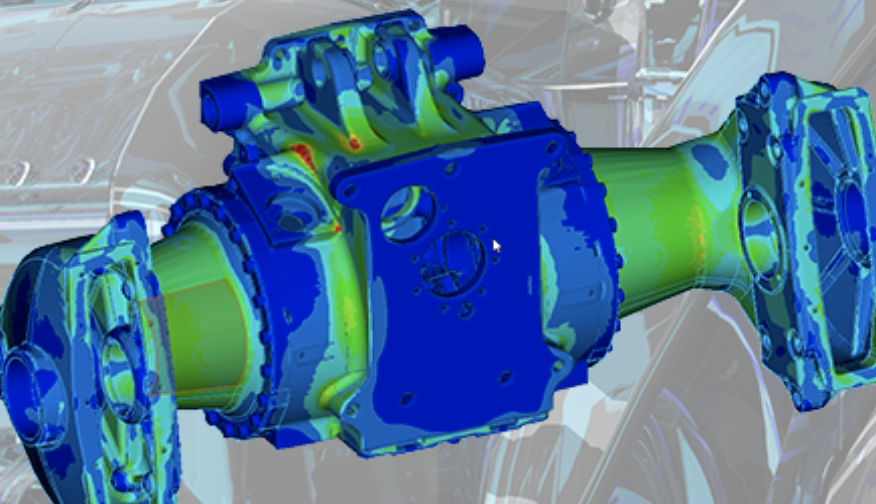

PTC’s Creo suite provides a wide array of simulation solutions tailored for every stage of the product lifecycle. Whether it’s early-stage design validation with Creo Simulation Live or high-fidelity analysis through Creo Ansys Simulation, Creo enables engineers to simulate real-world performance. All of this is done before creating a single physical part.

Creo Simulation capabilities include:

- Finite Element Analysis (FEA): Simulate structural stress, thermal response, and vibration.

- Mechanism Dynamics: Analyze motion, interference, and component interactions.

- Computational Fluid Dynamics (CFD): Understand airflow, fluid behavior, and thermal distribution.

- Generative Design (GTO/GDX): Use AI to auto-generate optimized designs based on defined goals.

- Behavioral Modeling: Evaluate how changes in one variable affect the entire system.

By embedding simulation within the design environment, Creo allows engineers to iterate faster and smarter without relying solely on downstream analysis teams or physical testing.

CAD Simulation Benefits

Reduce Prototyping Costs

Physical prototypes are expensive. With Creo Simulation, engineers can identify potential issues, such as structural failure, thermal hotspots, or motion collisions, before anything is built. This dramatically reduces the number of prototypes required, saving materials, labor, and time. According to industry data, 46% of companies report fewer prototypes when simulation is used early. To add to this, 40% see a reduction in costly design rework.

Improve Design Accuracy with CAD

Creo’s real-time feedback (via Creo Simulation Live) and high-fidelity Ansys-powered tools ensure design decisions are backed by real-world physics. Simulation helps ensure the product meets performance, safety, and quality benchmarks, the first time. This means whether you are validating a brand-new concept or refining a carry-over component, it will be well-tested.

Accelerate Time-to-Market

Traditional design-analysis cycles often slow progress. Simulation-driven design (SDD) shifts simulation “left” in the development process, giving engineers rapid insights from the start. This shortens development cycles, supports faster ramp-up, and ensures decisions are based on performance.

Drive Continuous Innovation

Creo doesn’t just help validate existing ideas, it encourages new, optimized ones. Through generative design and Design Exploration, engineers can uncover novel solutions, differentiate their products, and maintain a competitive edge.

Creo and SPK: A Partnership for Simulation Success

At SPK and Associates, we’ve helped organizations across regulated and high-tech industries integrate Creo Simulation into their engineering workflows. Our team of experts partners with you to implement Creo tools like Simulation Live and Ansys Simulation. Additionally, we can help customize simulation workflows based on your product type and industry standards. We also specialize in training your teams to use CAD simulation early and often. Our experts can even integrate simulation-driven design into your digital thread. This enhances traceability and compliance. Whether you’re designing an entirely new product or refining an existing platform, SPK ensures you unlock Creo’s full simulation potential. Overall, we can help reduce waste, improve performance, and accelerate delivery.

Reducing Prototyping Costs and Improving Design Accuracy with Creo Simulation

Simulation is not an optional step. Instead, it is a strategic advantage. By adopting Creo Simulation tools, companies can reduce prototyping costs, improve design accuracy with CAD, and bring better products to market faster. When combined with SPK and Associates’ expertise, Creo becomes the engine of innovation. If you are ready to revolutionize your product development process, contact SPK. Together, we can transform your engineering outcomes.