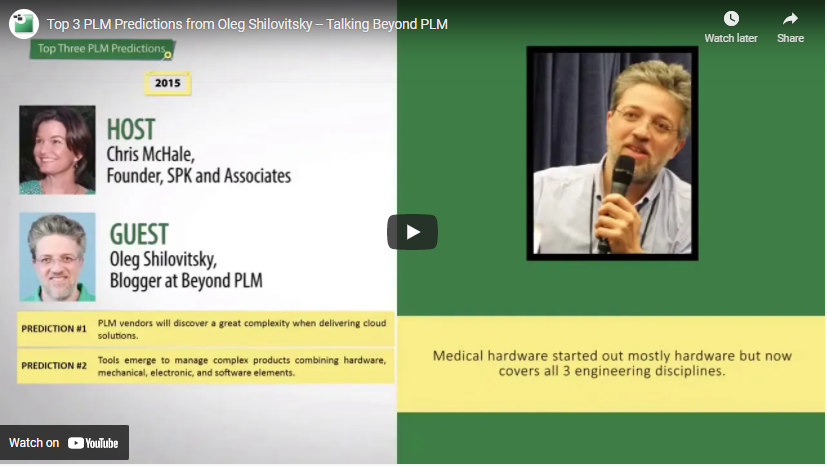

SPK and Associates co-founder Chris McHale recently spoke with PLM expert Oleg Shilovitsky, founder of BeyondPLM.com, to get his top three product lifecycle management (PLM) predictions for 2015.

1. PLM vendors will encounter greater complexity when delivering cloud solutions

Cloud solutions may have gone largely unnoticed a few years ago, but today almost all PLM companies have established cloud strategies. In 2015 Oleg predicts that PLM will begin to discover that switching to the cloud means a lot more than moving servers. As vendors realize that the complexities of maintaining, implementing, and running services on the cloud, some vendors will have to adopt an additional role of software service provider. As a result, we’ll start to see inherent differences between born-in-the-cloud vendors and server-to-cloud vendors.

2. New tools will emerge to manage complex products combining hardware, mechanical, electronic, and software elements

Advances in technology mean that products spanning multiple disciplines surround us. Modern household devices – like an electronic lock – can contain mechanical, electrical, and software components. As the trend towards more highly integrated products continues, new tools aimed at helping product manufacturers manage the complexity of all the different engineering disciplines will emerge. According to Oleg, bringing together mechanical, software, and electrical engineering – as well as CAD – through software will become critical.

3. A new type of collaborative, distributed manufacturing company will attract both CAD and PLM vendors

Thanks to the internet, globalization, and new methods of product development, we’re at the cusp of the next industrial revolution lead by a new type of manufacturing company: One that is smaller, more agile, and crowdfunding based. Through collaborative efforts, distributed working, and new technology like 3D printing, small companies and even individuals are now capable of entering the market with real manufactured products made from scratch. 2015 will see both PLM and CAD vendors offering globally-accessible solutions to this new type of manufacturing organization.

Next Steps:

- Contact SPK and Associates to see how we can help your organization with our ALM, PLM, and Engineering Tools Support services.

- Read our White Papers & Case Studies for examples of how SPK leverages technology to advance engineering and business for our clients.