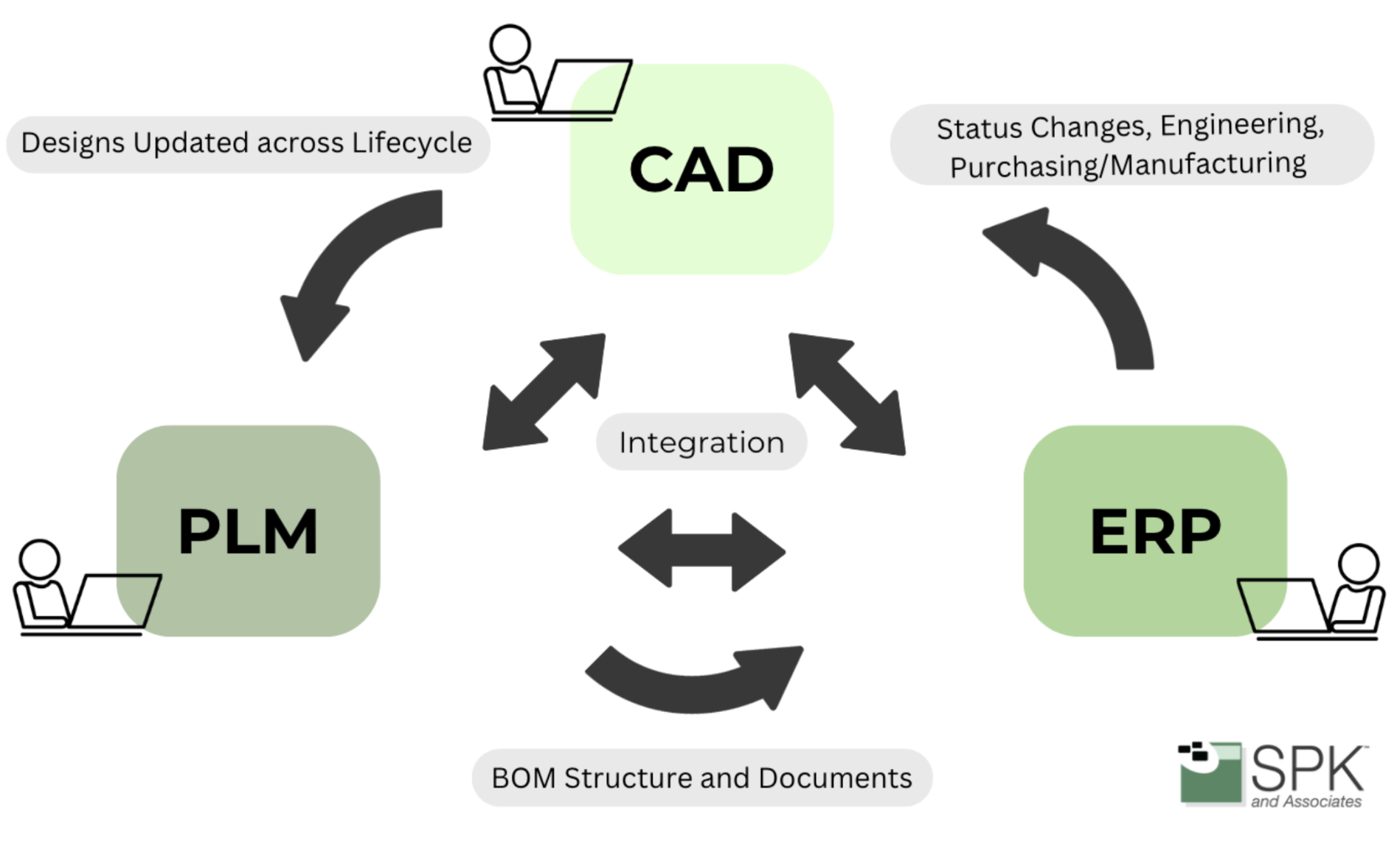

Managing data across multiple systems can quickly become complex and overwhelming. This issue is common for companies across industries. Trying to manage all product-related data and CAD designs across multiple PLM and ERP systems often results in siloed data. This costs business time and money due to duplicated efforts and inefficiencies. Ensuring accurate data synchronization can be expensive, but streamlining your data ecosystem with the right tools can provide cost reductions. Discover what a proper data environment can do for you.

The Issue of Inefficient Data Systems

When companies rely on multiple systems to manage their product-related data with no integrations, problems arise. Oftentimes employees on separate teams will work with different versions of the same data. Using data that is not up-to-date leads to wasted time due to rework. For example, an engineer might update a CAD model in PTC Creo. If that update doesn’t seamlessly flow into the company’s PLM system or ERP platform, the business risks using outdated or incomplete information.

Maintaining these separate systems comes at a cost both in terms of resources and the business impact of using incorrect data. High-maintenance infrastructures cause project delays and lead to inefficiencies in production and engineering. At SPK, we help businesses optimize their data environments. As a licensed PTC partner, we often leverage solutions such as Creo for CAD and Windchill for PLM. We’ve seen firsthand how syncing these systems with ERP and other enterprise software can revolutionize an organization’s approach to data.

Integrated PDM, PLM, and ERP Systems

The solution to these challenges is creating a well-integrated data ecosystem. While Windchill is a PLM tool, it can also function as a PDM tool, allowing companies to centralize CAD data. This ensures that any updates in Creo are automatically reflected in the PLM system. Windchill’s ability to keep data up-to-date eliminates the need for manual data entry or synchronization which reduces the chance of error for your business. A synchronized PLM system not only connects product design with manufacturing data but also aligns with ERP systems to provide a holistic view of the product lifecycle. This level of integration leads to a more efficient workflow and lowers IT maintenance costs.

How PDM and PLM Drive Cost Reduction

While implementing integrated PDM and PLM systems requires an initial investment, the long-term savings are undeniable. Eliminating duplicated efforts ensures that everyone within the organization is working with the most up-to-date data, leading companies to:

- Make Better Decisions: With synchronized data across CAD, PLM, and ERP, decision-makers have access to accurate and real-time information. This reduces costly mistakes, enables proactive decision-making, and improves responsiveness to market demands.

2. Improve Time-to-Market: Integrated data flows also reduce problems in engineering changes and production. With faster decision-making, businesses can bring products to market more quickly.

3. Enhance Customer Insights: When product-related data is unified, companies gain a clearer view of their customer base and market trends. This helps businesses predict demand, optimize their inventory, and improve customer satisfaction.

4. Reduce IT Overhead: By consolidating data systems, businesses can reduce the burden on their IT departments. Fewer systems mean fewer upgrades and less maintenance. This not only lowers costs but frees up IT resources to focus on bigger priorities.

The Benefits of a Product Data Ecosystem

At SPK we’ve seen first-hand how powerful solutions form the backbone of an integrated data ecosystem. Two tools we know we can count on are Windchill PLM and PTC Creo. When these tools are integrated with ERP systems, they eliminate data silos, providing a unified source of truth for product information. Whether you’re managing complex CAD designs or orchestrating product lifecycle processes, having synchronized data flows reduces complexity and optimizes costs. More importantly, it provides better insights, positioning your business to adapt quickly to market changes.

Streamline Your Data Ecosystem Today

Streamlining your data ecosystem isn’t just smart financially, but it empowers your teams to work smarter. Integrating PDM, PLM, ERP, and CAD allows you to eliminate errors. At SPK, we specialize in helping businesses optimize their data environments by implementing these cutting-edge solutions. Contact us today to learn how we can help transform your data management strategy.