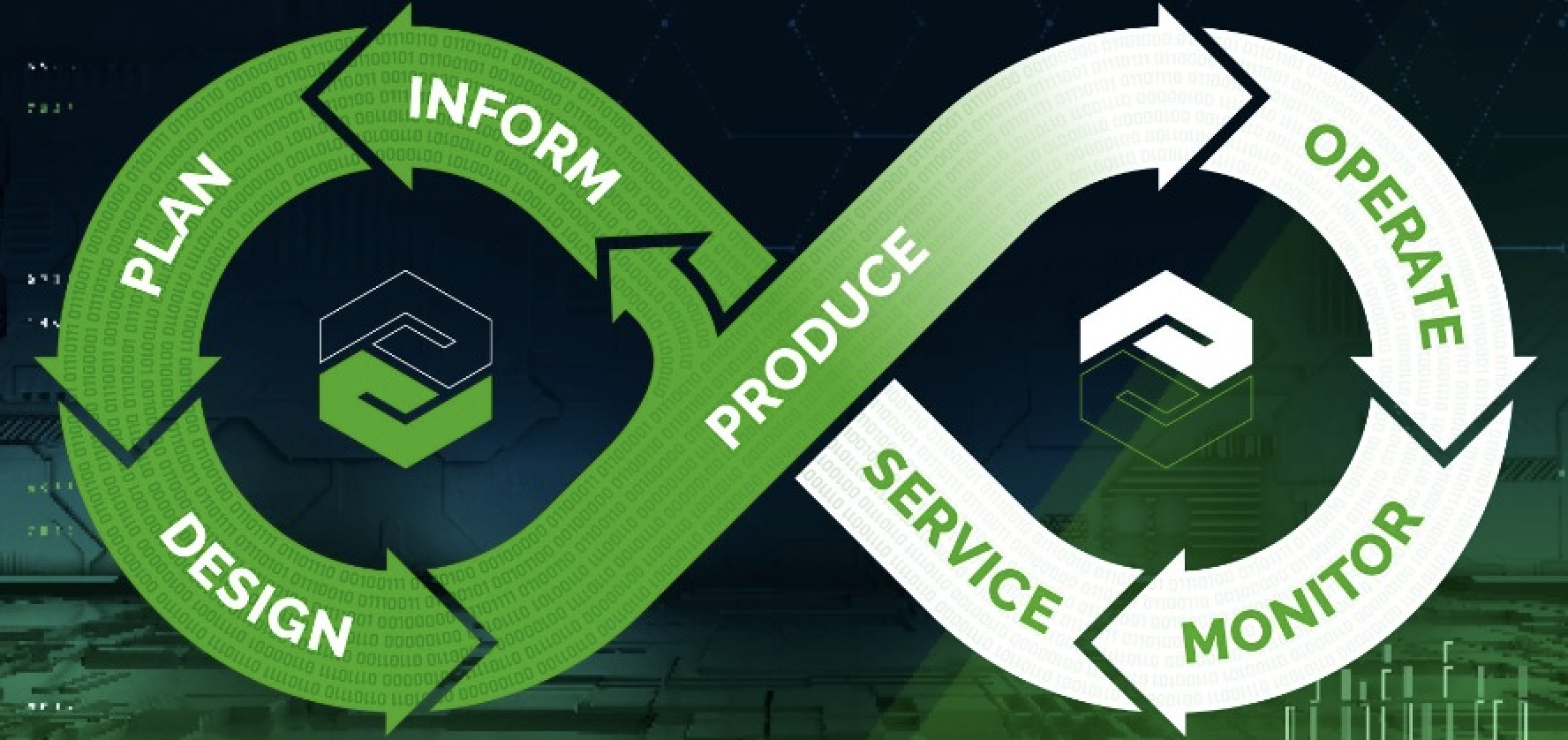

Medical device companies are facing unprecedented pressure. Regulatory expectations continue to rise, product and software complexity are accelerating, and embedded software is now central to nearly every device. At the same time, patients and providers demand faster innovation without compromising safety or quality. As a result, leading organizations are adopting an intelligent product lifecycle—one where artificial intelligence is embedded directly into engineering, quality, manufacturing, and service workflows. Rather than treating AI as a standalone analytics layer, these companies are integrating intelligence into the systems and processes that power day-to-day execution. The result is faster development cycles, stronger compliance, lower costs, and more resilient operations. At the center of this shift is PTC’s Intelligent Product Lifecycle, powered by AI and enabled by a unified data foundation.

The Three Pillars of the Intelligent Product Lifecycle

An intelligent product lifecycle is built on three interconnected pillars:

- A unified product data foundation

- Intelligent, AI-enabled solutions

- Embedded AI agents that automate and optimize work

Together, these pillars transform how MedTech organizations design, build, support, and improve medical devices.

Pillar 1: The Product Data Foundation

Creating a Unified Backbone from Requirements to Service

AI is only as effective as the data it can access. In many MedTech organizations, product information remains fragmented across disconnected systems for requirements, design, quality, manufacturing, and service. This fragmentation creates blind spots, slows decision-making, and increases regulatory risk. A product data foundation solves this problem by establishing a single, connected backbone that links:

- Product requirements and specifications

- Design models and CAD data

- Bills of materials and manufacturing records

- Quality, risk, and compliance documentation

- Service, asset, and field performance data

With platforms like PTC Windchill, Creo, and ServiceMax, organizations create a digital thread that follows each product from concept through end-of-life. This unified foundation enables real-time visibility into changes and dependencies and end-to-end traceability for regulatory compliance. It also provides faster impact analysis for design updates and offers better reuse of proven components and designs. This digital thread is the essential data layer that makes advanced AI capabilities possible.

Pillar 2: Intelligent Solutions

Turning Product Data into Actionable Insight

Once data is unified, AI-enabled solutions can begin improving performance across the lifecycle. Rather than relying on manual processes and disconnected reports, intelligent solutions continuously analyze product and process data to surface risks, optimize designs, and automate compliance.

Improving New Product Introduction (NPI)

Many MedTech organizations experience excess NPI cycle time due to:

- Manual Device History File and compliance documentation

- Poor synchronization between design and development

- Late discovery of requirement changes

- Limited visibility into prior designs

These issues can account for up to 20% excess NPI effort. AI-powered lifecycle solutions address these challenges through automated regulatory management and report generation, model-based design with 3D models as the source of truth, and parts and assembly rationalization for reuse. The continuous traceability across R&D, manufacturing, and service allows teams to move faster without increasing risk.

Reducing the Cost of Quality

Quality failures are expensive in regulated environments. Scrap, rework, recalls, and warranty claims often stem from outdated documentation, manual compliance processes, and disconnected requirements. Excess cost of quality can reach 10% or more.

Intelligent solutions help by enabling:

- Unified hardware and software requirements traceability

- Automated compliance documentation

- AI-powered audit readiness

- Closed-loop feedback from service and field data

This creates a proactive quality system that prevents issues rather than reacting to them.

Pillar 3: AI Agents

Embedding Intelligence into Daily Operations

The third pillar of the intelligent product lifecycle is the emergence of AI agents. These are embedded assistants that operate within PLM, ALM, QMS, and service platforms to automate routine work and support decision-making. Unlike traditional analytics tools, AI agents actively participate in workflows.

Examples include:

- Automatically generating compliance reports

- Monitoring change impact across systems

- Identifying risk hotspots in requirements and designs

- Optimizing service scheduling and parts allocation

- Supporting audit preparation and documentation

These agents reduce administrative burden while improving consistency and accuracy, which is critical in regulated environments.

Real-World Impact: MedTech Case Studies

PTC’s Intelligent Product Lifecycle is already helping these companies in the MedTech space.

Fresenius: Accelerating Change Management

Fresenius implemented automated compliance file creation and model-based design tracking across its product lifecycle. By leveraging AI-enabled PLM and digital thread capabilities, the company achieved a 76% reduction in change cycle time and a 10-day decrease in approved lead time. These improvements allowed them to respond faster to regulatory and market changes without increasing risk.

GE Healthcare: Optimizing Service and Inventory

GE Healthcare uses ServiceMax to connect service technicians, asset data, and inventory systems. With AI-powered scheduling and analytics, technicians can:

- Access asset history in real time

- Verify part availability before dispatch

- Capture service data digitally

- Improve first-time fix rates

As a result, GE Healthcare achieved a 10% inventory reduction, 8% improvement in fill rate and service levels, and a 40% reduction in call center volume. This demonstrates how intelligence embedded in service operations directly improves customer experience and operational efficiency.

How SPK Helps MedTech Organizations Build Intelligent Lifecycles

Technology alone does not create an intelligent product lifecycle. Success requires the right architecture, governance, integrations, and change management. As a PTC partner with deep experience in regulated industries, SPK helps MedTech organizations:

- Design unified PLM, ALM, and QMS architectures

- Establish digital thread and traceability frameworks

- Integrate Creo, Windchill, ServiceMax, and related systems

- Automate compliance and audit workflows

- Prepare data environments for AI and agent adoption

- Optimize licensing, security, and validation

SPK’s approach focuses on building a scalable data backbone that supports both current regulatory needs and future AI innovation.

Building Intelligence Into Every Stage of Innovation

The future of MedTech innovation requires embedded intelligence, and organizations that succeed will have established a strong product data foundation. With the right strategy, platforms, and partners, MedTech companies can transform digital transformation into intelligent transformation. With SPK and PTC, that future is already within reach. If you are ready to jump into modern innovation, contact our experts.