Manufacturing execution systems (MES) are evolving faster than ever. Rising sustainability requirements, ongoing workforce shortages, increasing product complexity, and tighter regulatory oversight are pushing manufacturers to rethink how they run shop floor operations. 2026 is the year MES platforms will be strategic enablers of operational excellence, quality, and resilience. Leading manufacturers are already adopting new approaches that combine cloud, AI, composable applications, and real-time analytics to stay competitive. In this article, we explore five key MES trends shaping 2026 and how manufacturers can get ahead of the curve.

1. Sustainability Built Into MES

Regulatory pressure, customer expectations, and cost considerations are forcing manufacturers to measure and reduce their environmental footprint, making sustainability a main priority.

Modern MES platforms are becoming central to green manufacturing initiatives by enabling:

- Real-time tracking of energy, water, and material usage

- Waste and scrap analysis by product and process

- Carbon footprint reporting at the production level

- Optimization of machine utilization and cycle times

By embedding sustainability metrics into daily operations, manufacturers can make environmentally responsible decisions without sacrificing productivity.

2. App-Based MES Platforms and Composable Operations

Traditional MES systems are often rigid, expensive to customize, and slow to adapt to changing requirements. By 2026, app-based and composable MES platforms will dominate the market.

One of the leaders in this space is Tulip, a frontline operations platform designed to digitize manufacturing without legacy system complexity.

Why App-Based MES Is Taking Over

Modern app-based platforms enable manufacturers to build exactly what they need, when they need it. Key capabilities include:

No-Code App Building: Teams can create interactive production, quality, and maintenance apps without writing code. Using templates or custom designs, organizations can deploy solutions quickly while maintaining governance and control.

Native AI and Machine Learning: Built-in AI enables document search, translation, and text extraction. Computer vision supports automated inspection and defect detection, all configurable without complex development.

System, Machine, and Device Connectivity: Tulip Edge Devices and open APIs connect machines, sensors, and enterprise systems bi-directionally. This allows manufacturers to automate workflows and eliminate manual data entry.

Powerful Analytics: No-code dashboards provide real-time visibility into performance, quality, and throughput. Machine learning models support forecasting and optimization.

App Suites, Templates, and Integrations: Composable MES app suites and pre-built integrations help teams get started quickly. Custom integrations remain possible through developer frameworks.

Security and Compliance: App-based platforms now support GxP compliance, electronic records, enforced data validation, and configurable approval workflows to meet regulatory requirements.

This composable approach allows manufacturers to evolve their MES continuously rather than replacing it every few years.

3. Cloud-Based MES as the New Standard

In addition to app-based solutions, On-premise MES deployments are steadily giving way to cloud-based platforms. By 2026, cloud MES will be the default choice for most manufacturers.

Key advantages include:

- Faster implementation and upgrades

- Elastic scalability across plants and regions

- Improved disaster recovery and resilience

- Reduced infrastructure and maintenance costs

- Easier integration with enterprise systems and analytics tools

Cloud-native MES platforms also enable rapid deployment of AI features and digital twins, making them essential for future-ready manufacturing. For regulated industries, modern cloud MES solutions now provide validated environments, security controls, and audit-ready architectures.

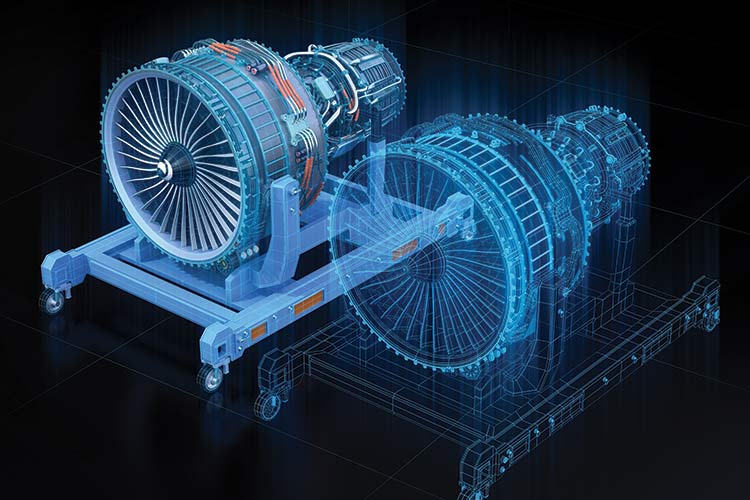

4. Digital Twins for Simulation, Optimization, and Continuous Improvement

Digital twins are becoming a foundational component of advanced manufacturing.

A digital twin is a virtual model of a production line, asset, or process that is continuously updated with real-time data from the shop floor.

Leading MES platforms will use digital twins to:

- Simulate production scenarios before implementation

- Optimize line balancing and scheduling

- Predict bottlenecks and failure points

- Test process changes virtually

- Improve capacity planning and throughput

When combined with AI, digital twins enable manufacturers to move from reactive problem-solving to proactive optimization. Instead of asking “What went wrong?” teams can ask “What will happen if we change this?” and get immediate, data-driven answers.

5. Customization and Personalized User Experiences

The modern manufacturing workforce expects intuitive, role-based digital tools similar to consumer applications. One-size-fits-all MES interfaces are no longer sufficient.

Leading MES platforms provide highly personalized user experiences for:

- Operators

- Quality engineers

- Maintenance technicians

- Supervisors

- Production managers

- Compliance teams

This includes features such as role-specific dashboards, context-aware workflows, guided work instructions, mobile and tablet-first interfaces, and adaptive alerts and notifications. App-based MES platforms make customization possible by allowing each role to use tailored applications built on a common data foundation. Personalization improves adoption, reduces training time, and minimizes human error.

Building the Future of Manufacturing Operations

Modern MES platforms can be intelligent, cloud-native, app-driven, and deeply connected to enterprise systems. They support sustainability initiatives, enable continuous optimization, and empower frontline workers with personalized digital tools. Manufacturers that take advantage of MES modernization will have a strategic advantage over their competitors. With platforms like Tulip and the right implementation partner, organizations can build composable, future-ready operations that scale with innovation, compliance, and market demands. The future of manufacturing execution is not just digital. It is intelligent, sustainable, and built for continuous evolution. Contact our experts today to learn more about modern MES solutions like Tulip.