Manufacturers operating in competitive, highly regulated markets understand that product quality does not stop at release. Once products reach the field, real-world operating conditions, usage patterns, and environmental stressors begin to reveal failure behaviors that were not always visible during design and testing. When these field-failure trends go unidentified or poorly understood, organizations face a familiar set of consequences: recurring quality issues, declining product performance, and steadily rising warranty and repair costs. Fortunately, tools like Windchill provide a structured, data-driven way to capture, analyze, and act on reliability and risk information across the entire product lifecycle. By connecting field data with engineering analysis, Windchill enables teams to move from reactive fixes to proactive quality improvement.

The Challenge: Unidentified Field-Failure Trends

When failure data is fragmented or analyzed too late, manufacturers struggle to answer fundamental questions. Why are products failing in the field? Which components are driving warranty costs? Are failures design-related, usage-related, or environment-driven?

Without clear visibility into failure rates and trends, organizations experience:

- Ongoing product quality and performance issues that repeat across product generations

- Escalating warranty repair costs driven by unaddressed root causes

- Inefficient maintenance programs and unplanned downtime

- Missed opportunities to optimize designs, materials, and operating limits

While many companies already collect large volumes of field data, the real gap is often in structure, integration, and statistical analysis. Quality field failure data can be the ultimate source of reliability insight when it is organized, contextualized, and analyzed correctly.

How Windchill Modules Help Identify and Predict Failures

Windchill brings together a comprehensive set of tools designed to quantify reliability, assess risk, and turn field data into actionable engineering insight.

Reliability Evaluation Modules

Windchill Prediction

Windchill Prediction estimates failure rates, MTBF, and system reliability using globally accepted standards such as MIL-HDBK-217, Telcordia SR-332, IEC TR 62380, and 217Plus. By accounting for operating conditions like temperature, environment, stress, and mission time, teams can evaluate whether a design is likely to meet reliability goals before issues reach the field. Early prediction helps identify high-risk components and quantify how failure rates scale across complex systems.

Windchill Markov

For systems with sequence-dependent states or complex operational behavior, Windchill Markov models reliability across multiple states and transitions. This is especially valuable for systems where redundancy, degradation, or operational sequences influence failure probability.

Windchill RBD

Reliability Block Diagrams allow teams to model redundancy, repair strategies, spares, downtime, and maintenance intervals. Windchill RBD supports simulation and optimization to evaluate how design and maintenance decisions affect overall system reliability and availability.

Risk Assessment Modules

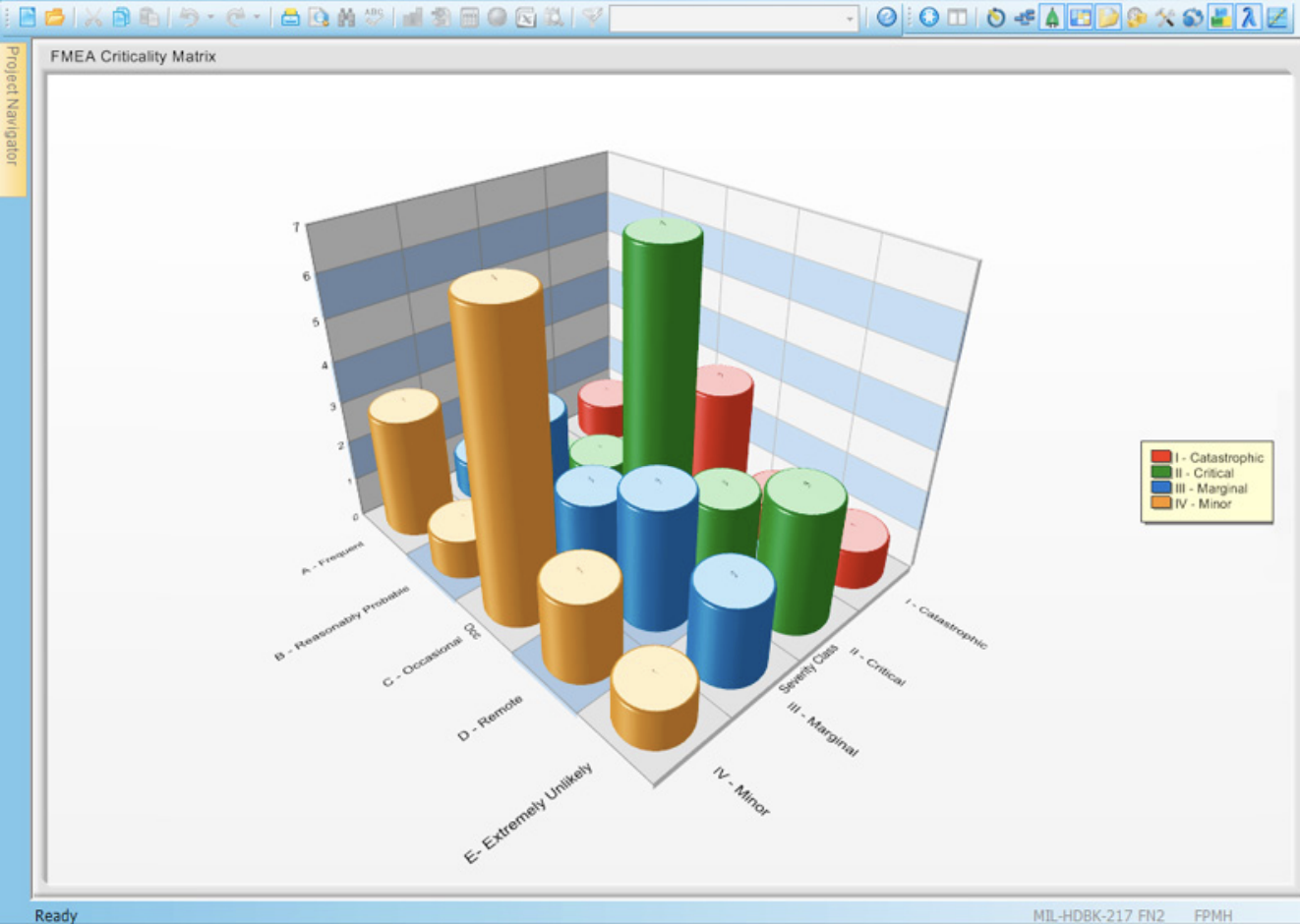

Windchill FMEA

Failure Modes and Effects Analysis systematically evaluates how component failures impact system performance and customer safety. By ranking severity, occurrence, and detectability, teams can prioritize corrective actions that reduce real-world risk.

Windchill FTA

Fault Tree Analysis identifies combinations of events that lead to system failures. This top-down approach helps engineering teams understand how individual failures propagate and where design improvements will have the greatest impact.

Windchill Event Tree

Event Tree Analysis examines possible outcomes following an initiating event, allowing teams to assess probabilities of different failure paths and consequences.

Specialized Reliability Tools

Windchill ALT

Accelerated Life Testing uses overstressed test data to predict product reliability under normal operating conditions. This enables earlier insight into long-term field performance.

Windchill FRACAS

Failure Reporting, Analysis, and Corrective Action System captures field incidents, customer complaints, and internal findings in a centralized system. FRACAS ensures issues are analyzed, corrective actions are implemented, and effectiveness is verified.

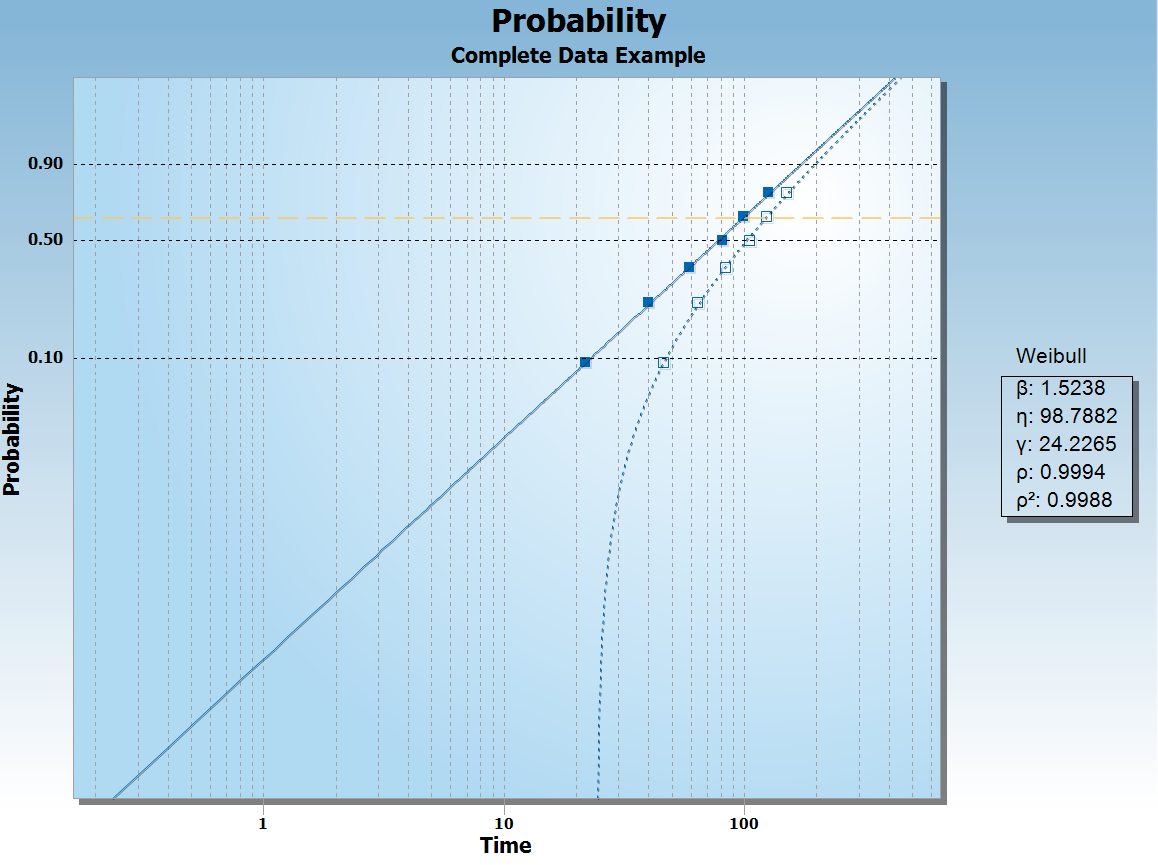

Windchill Weibull

Weibull analysis uses actual field failure data to model failure distributions and forecast future failures. This is critical for identifying early-life failures, wear-out trends, and reliability growth opportunities.

Windchill Maintainability

Maintainability analysis estimates mean time to repair, helping teams design products and service strategies that reduce downtime and customer impact.

Windchill LCC

Life Cycle Cost analysis evaluates the total cost of ownership by factoring in failure rates, repair costs, maintenance strategies, and operational impacts. This connects reliability decisions directly to financial outcomes.

Turning Field Feedback Into Higher-Quality Products

The true value of Windchill emerges when these modules work together as a closed-loop system. Field failure data captured through FRACAS and customer feedback feeds directly into Weibull analysis, FMEA updates, and reliability predictions. Internal service teams, quality engineers, and design engineers all work from the same data foundation.

This integrated approach enables organizations to:

- Detect emerging failure trends earlier using real field data

- Quantify how failure rates scale across fleets and operating hours

- Prioritize corrective actions based on risk, cost, and customer impact

- Optimize maintenance schedules and reduce unplanned downtime

- Feed lessons learned back into design standards and next-generation products

By combining prediction models with actual field performance, teams gain confidence that reliability improvements are measurable, verifiable, and aligned with customer experience goals.

Decoding Field Failure Trends with Windchill

Unidentified field-failure trends quietly erode product quality, customer trust, and profitability. Windchill gives manufacturers the tools they need to uncover those trends, quantify failure behavior, and act decisively. By integrating reliability prediction, risk assessment, and field feedback into a unified framework, organizations can reduce warranty costs, improve product performance, and deliver higher-quality products that stand up to real-world demands. Decoding field failures is not just about fixing what broke. It is about building a data-driven culture of reliability that turns every field insight into a competitive advantage. If you want to see how Windchill can help maintain product quality, reach out to our experts.