Most manufacturers track overall equipment effectiveness (OEE) as a standard for productivity. The challenge is not collecting this number, but turning the number into action on the shop floor. Too often, OEE becomes a static KPI that shows whether performance was good or bad. It should instead be used as a signal that drives continuous improvement and daily decision-making. When OEE data is connected to real-time visibility, root cause analysis, and follow-up actions, it becomes a powerful engine for operational improvement. This is where modern, digital-first approaches can make a huge difference.

The Importance of OEE

OEE gives manufacturers a shared, objective way to understand where time, capacity, and quality are being lost. It brings availability, performance, and quality into a single lens that highlights how effectively assets are being used during planned production time. More importantly, OEE creates alignment. Operators, supervisors, engineers, and plant managers can all look at the same metric and agree on where attention is needed. That alignment is what makes OEE such a valuable starting point for improvement efforts. However, OEE alone does not explain why losses occur. It tells you that something is wrong, not what to fix next. To unlock its full value, OEE must be paired with context, drill-downs, and clear ownership for corrective action.

Benefits of Using OEE for Manufacturers

When OEE data is used actively, manufacturers see tangible benefits across operations:

Clear prioritization of improvement efforts

OEE highlights whether losses are driven by downtime, slow cycles, or quality issues, helping teams focus on the highest-impact problems instead of guessing.

Stronger ROI on equipment and automation investments

By understanding where capacity is underutilized, manufacturers can delay unnecessary capital purchases and get more from existing assets.

Reduced downtime and maintenance surprises

Patterns in availability losses help maintenance teams plan smarter interventions instead of reacting to failures.

Higher product quality and lower scrap

Visibility into quality losses enables faster feedback loops and targeted process corrections.

Data-driven decision-making across shifts and sites

Consistent OEE tracking creates a common language for performance discussions, from daily standups to executive reviews.

The biggest gain comes when OEE data flows directly into continuous improvement workflows rather than living in spreadsheets or end-of-shift reports.

Tulip’s OEE Dashboard: From Visibility to Action

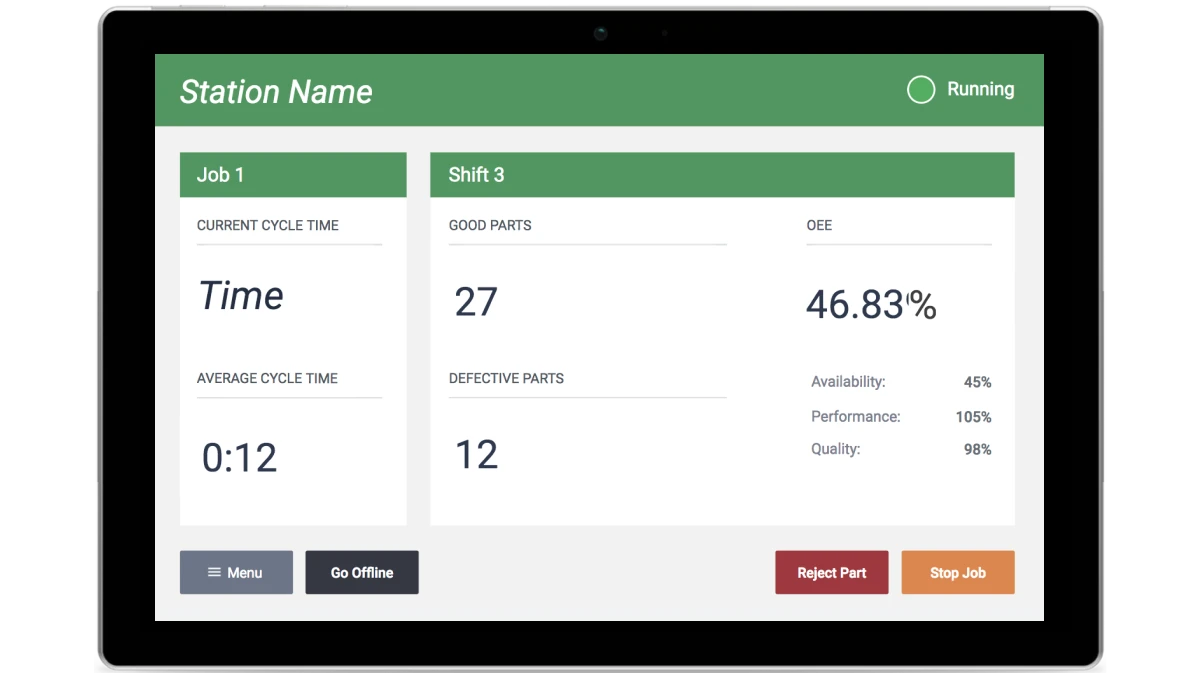

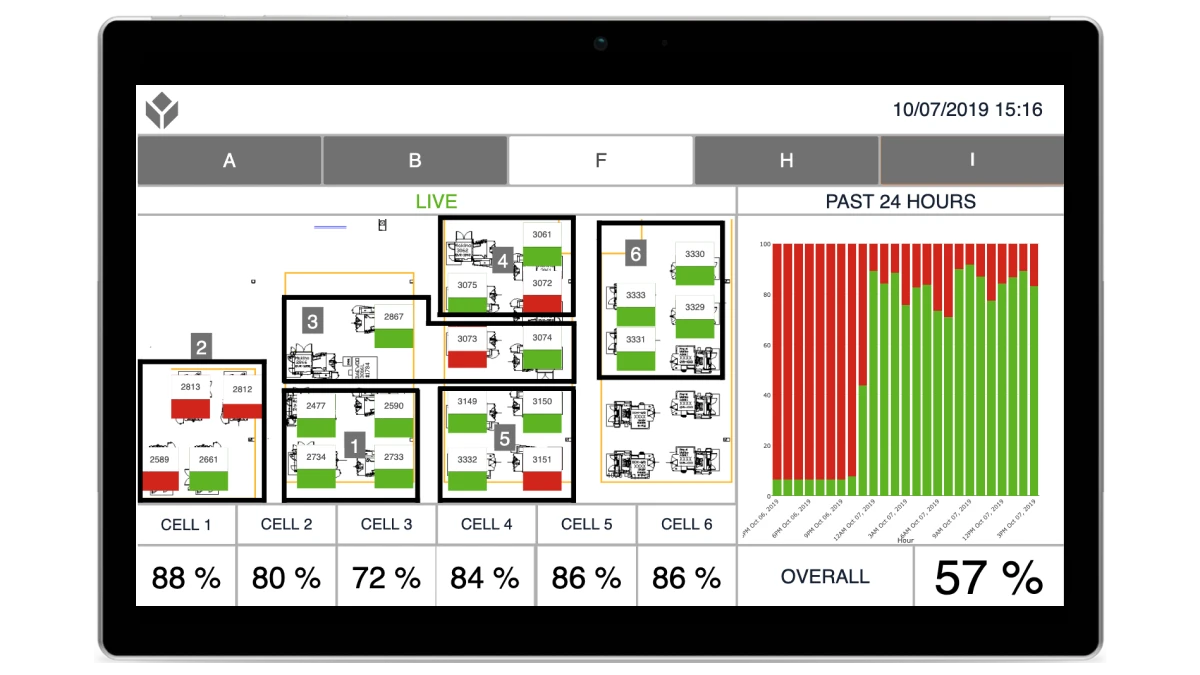

One of the best ways to actively use your OEE data is by integrating modern platforms into your manufacturing operations. Platforms like Tulip can change how manufacturers use OEE. Tulip’s OEE dashboards are designed to move beyond reporting and into execution. Instead of showing isolated numbers, they connect machine data, operator inputs, and contextual information into a real-time view of performance.

Key capabilities include:

- Real-time machine monitoring

Live data from equipment means teams see issues as they happen, not hours later. - Flexible views by role

Operators can focus on cycle time and downtime reasons, supervisors on shift performance, and leaders on trends across lines or facilities, all without custom code. - Built-in OEE calculations

A consistent, automated approach ensures everyone is working from the same definition of availability, performance, and quality. - Drill down into root causes

OEE scores can be paired with downtime reasons, changeover data, and quality metrics to quickly identify what is driving losses. - Closed-loop improvement

Insights from the dashboard can trigger corrective actions, work instructions, or follow-up tasks, turning insight into execution.

Tulip is a no-code platform, so teams can adapt dashboards as processes evolve. That flexibility is critical for continuous improvement, where yesterday’s metrics may not answer tomorrow’s questions.

The Future of OEE

OEE remains one of the most valuable performance indicators in manufacturing, but only when it is treated as a starting point rather than the finish line. On its own, OEE shows where productivity is leaking. When combined with real-time dashboards, contextual data, and closed-loop improvement processes, it becomes a driver of measurable change. By using digital tools like Tulip to connect OEE insights directly to action on the shop floor, manufacturers can move faster, reduce waste, and build a culture of continuous improvement that delivers lasting results. If you are interested in learning more about Tulip, contact our experts.