When you’re a discrete manufacturer, your product designs and data are the crown jewels of your business. They define your intellectual property, drive your revenue, and differentiate you from the competition. Entrusting that IP to a CAD or PLM software vendor is a strategic move that deserves careful scrutiny. If you’re evaluating CAD and PLM solutions, here are six critical questions you should ask any vendor before you commit.

Understanding CAD and PLM for Your Unique Business Needs

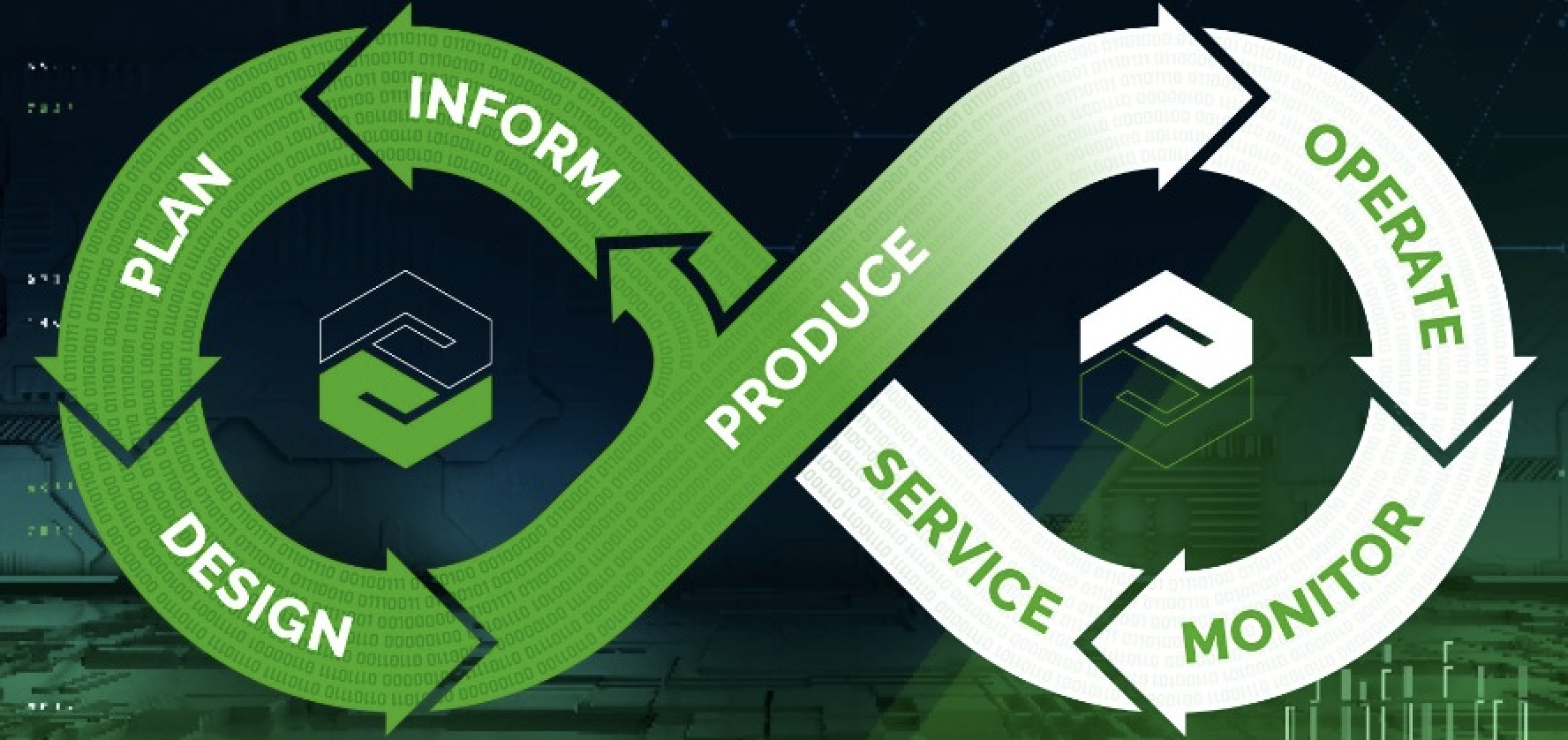

CAD (Computer-Aided Design) and PLM (Product Lifecycle Management) systems are the backbone of modern manufacturing. They connect your people, processes, and data from initial design through production, maintenance, and beyond. This single digital thread improves collaboration, reduces errors, and speeds up your time to market. It is important to understand that not all solutions are created equal. Some vendors lock you in with rigid systems that limit your choices and flexibility. Others, like PTC’s Creo and Windchill, are designed to be open, giving you the freedom to adapt your tech stack as your business evolves.

6 Questions to Ask Your Vendor

1. Does the vendor use an open strategy?

It is important to ask if their platform is open by design, allowing you to integrate third-party tools when needed. On the contrary, you could be locked into a closed ecosystem that restricts interoperability. A closed system means you take what you’re given and pay what they demand.

2. Will there be knots in your digital thread?

The goal of a digital thread is seamless, accessible product data from design to the shop floor. Ask how your chosen system ensures every stakeholder has the right data, at the right time and what parts of your company might be left behind if integrations are limited.

3. Can you get your data back out?

Circumstances change. If you ever need to switch systems, how easily can you extract and validate your designs and product data? Vendor lock-in shouldn’t mean losing control over your IP or facing costly, disruptive data migrations later.

4. How will you stay up to date with the latest innovations?

In a closed system, you’re reliant on one vendor’s development roadmap, whether it aligns with your strategy or not. An open system lets you bring in new tools and best-of-breed technologies as your needs evolve.

5. What are you really trying to achieve and does this system support it?

Before you sign, step back. Think of the alternatives you have considered. What are the long-term consequences of consolidating all your product data in one vendor’s closed system? A healthy dose of skepticism protects your future.

6. Do you understand the true cost of change?

Beyond licensing fees, factor in the hidden costs of switching systems. This could mean potential productivity loss, retraining, morale dips, integration work, and unforeseen complications. A poor fit can cost far more than you bargained for.

Partnering with PTC and SPK

At SPK and Associates, we believe you deserve choice and control. That’s why we partner with PTC, whose leading CAD tool Creo and PLM platform Windchill are designed as open systems. They integrate flexibly with other tools, giving you the freedom to build a best-fit solution for your business. When you work with SPK, you get more than just software, you gain a trusted partner. We help guide you through implementation, integrations, migrations, and strategy, ensuring your IP stays secure and your workflows stay agile.

Selecting a CAD/PLM Software Vendor

Your product designs are too valuable to hand over blindly. Asking tough questions today helps you avoid regrets tomorrow. Choose a CAD/PLM partner who earns your trust and helps you get better products to market faster.

Ready to make an informed choice? Talk to SPK today about how Creo and Windchill can support your innovation.