Product Lifecycle Management (PLM) solutions are evolving with advances in cloud computing, AI, automation, and sustainability initiatives. For engineering leaders, staying ahead of these changes is critical to driving innovation, maintaining compliance, and improving time-to-market. In this blog, we’ll explore key PLM trends, highlight the future of PLM technology, and share actionable insights that leaders can use to strengthen their organizations.

The Future of PLM: Cloud PLM

Cloud PLM is reshaping how companies manage their product data. Unlike traditional on-premises PLM, cloud solutions provide real-time global collaboration, scalability, and reduced infrastructure costs. PTC’s Windchill+ is leading this shift. Windchill+ offers a secure, subscription-based model that adapts to evolving business needs.

If a cloud-based solution is not in the cards for your organization, you can stay up-to-date with a cloud-hosted solution. Partnering with SPK and Associates provides you with managed services and cloud hosting for Windchill. These services ensure enterprise-grade security, scalability, and performance. Our expertise allows organizations to focus on innovation rather than infrastructure, enabling faster time-to-market and more resilient PLM systems.

PLM Trend: AI and Machine Learning

AI is becoming a competitive necessity for product lifecycle management. However, without clean, accessible, and connected data, AI cannot deliver meaningful results. In PLM, data is the lifeblood that fuels smarter decision-making. The more organizations consolidate and contextualize this information, the greater the impact AI will have.

In the coming years, natural language processing (NLP) will become more prevalent. Users can utilize NLP to analyze specifications, documents, and design files, automatically surfacing insights and improving validation processes. Machine learning can detect patterns in existing parts, drawings, or supplier data, which ensures data reuse. This helps engineers avoid redundant designs and reduce overall costs. In addition to this, AI assistants will improve. They will streamline change management, automate task scheduling, and even provide interactive support for customer service and maintenance teams. Furthermore, tools like AI-driven search simplify complex PLM systems, making them more intuitive and accessible to engineers. Beyond these examples, the integration of technologies like IoT, computer vision, knowledge graphs, and rule-based systems will further expand the role of AI in PLM. The ultimate goal is to empower engineering leaders to make faster, better-informed decisions.

Automation in PLM

Automation within PLM reduces manual errors, streamlines processes, and accelerates development cycles. Key areas include:

- Change management: Auto-routing approvals and ensuring compliance.

- BOM management: Synchronizing and validating product structures across engineering and manufacturing.

- Documentation control: Automating versioning, validation, and notifications.

Digital Twins and The Digital Thread in PLM

The digital twin, a real-time digital representation of physical assets, is revolutionizing how companies design, test, manufacture, and service products. Unlike static simulations, digital twins are a living model that mirrors the performance and behavior of their physical counterpart. By doing so, digital twins help organizations solve some of the most pressing challenges in product development and operations, such as inefficient operations, unnecessary downtime, poor customer experience, and substandard product quality.

Beyond solving immediate challenges, digital twins also unlock strategic benefits. They enable organizations to:

- Enhance supply chain agility and resilience by modeling end-to-end visibility and adapting to disruptions in real time.

- Reduce time-to-market with continuous field insights that accelerate innovation cycles.

- Create new business models, such as product-as-a-service offerings that leverage richer product data.

- Increase customer satisfaction with predictive maintenance and improved service operations.

- Drive sustainability efforts by identifying opportunities to lower carbon emissions, optimize materials, and reduce waste.

- Improve productivity through remote monitoring and knowledge retention, even during workforce transitions.

- Expand data visibility across the enterprise by consolidating both historical and real-time data into one actionable view.

The digital thread connects these insights across the entire product lifecycle. Acting as the backbone, PLM systems manage and contextualize the data that feeds digital twins, ensuring compliance, traceability, and quality are embedded at every stage. Together, the digital twin and digital thread provide end-to-end visibility and continuous improvement, empowering engineering leaders to innovate faster, reduce risks, and deliver products that meet rising expectations for performance, quality, and sustainability.

The Trend of Sustainability and Digital Transformation

Sustainability is vital for the future of PLM. PLM plays a pivotal role in helping organizations design greener products and track environmental KPIs such as carbon footprint and packaging impacts.

By tightly linking sustainability and digital transformation, PLM helps businesses:

- Swap materials for sustainable alternatives.

- Reduce manufacturing waste and energy use.

- Monitor supplier compliance with sustainability goals.

- Embed environmental criteria directly into the product digital thread.

Engineering leaders who prioritize sustainability through PLM will not only meet regulatory demands but also win customer trust and long-term market relevance.

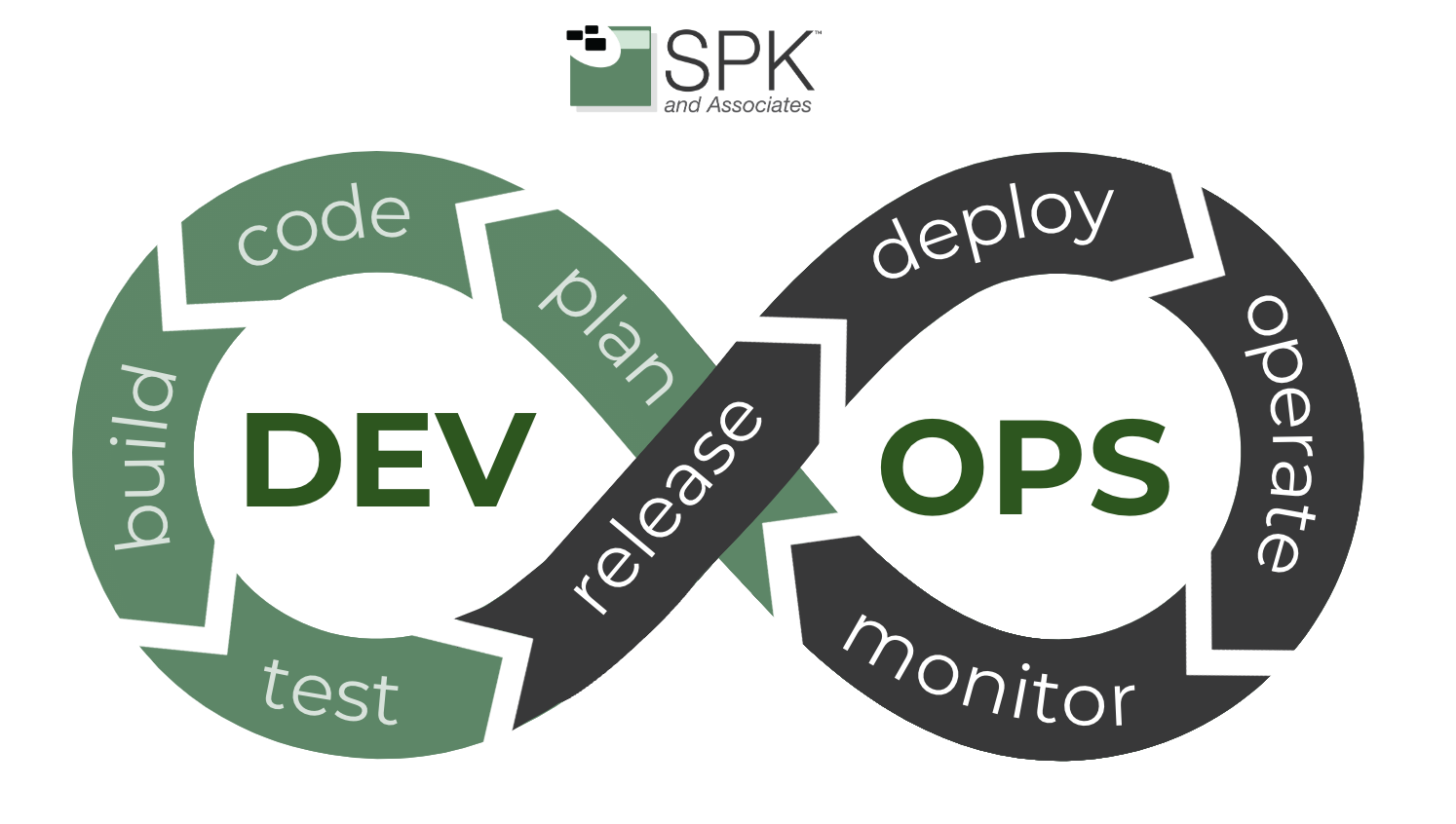

Adopting Agile and DevOps Methods in Product Teams

Hardware and software development are converging, and legacy waterfall methods no longer suffice. By adopting Agile and DevOps principles within PLM, teams can work iteratively to refine designs in shorter cycles. Applying these principles also fosters cross-functional collaboration across engineering, procurement, and manufacturing. This leads to improved change management with real-time transparency and enhanced quality assurance through continuous testing and feedback loops.

PLM tools are evolving to support Agile workflows, ensuring teams can deliver faster while maintaining traceability and compliance. This fusion of Agile and PLM is critical for the next generation of complex product development.

The Future of PLM Technology

The future of PLM is defined by the cloud, AI, automation, digital transformation, sustainability, and agile practices. Engineering leaders who embrace these PLM trends will position their organizations to be more innovative, efficient, and resilient in a competitive global market. At SPK and Associates, we specialize in helping organizations unlock the full potential of PLM. Whether we are implementing PTC Windchill+, hosting Windchill securely in the cloud, or guiding digital transformation strategies, we ensure your organization stays with the trends. Contact us today to discover how our experts ensure your PLM investments deliver measurable business outcomes.