The speed and efficiency of product development can make or break a company’s success. As a consulting company, we see it often. SPK and Associates not only helps companies purchase Creo licenses, but we also provide expert consulting services to aid your business in the transition to Creo or Creo+. Additionally, we help our clients become a Model-Based Enterprise (MBE), positioning them for sustained growth and innovation. Throughout that journey, product development teams must employ particular approaches in order to innovate faster.

The Power of Model-Based Design (MBD)

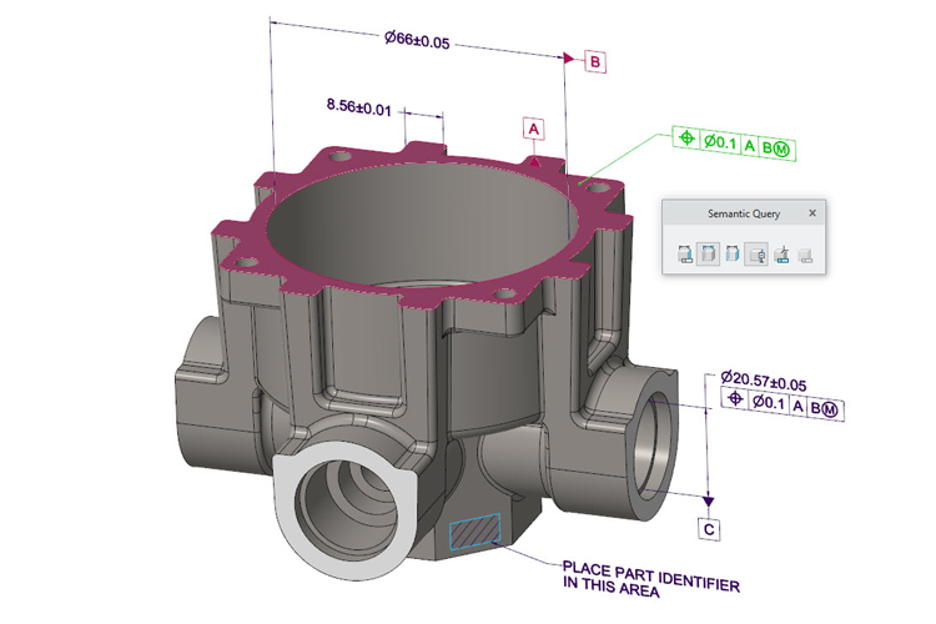

Model-Based Design (MBD) is a transformative approach in the world of product development. By documenting all necessary information—such as dimensions, tolerances, and annotations—directly within 3D CAD models, MBD eliminates the need for traditional 2D production drawings. This shift enables organizations to reduce costs, accelerate time-to-market, and enhance product quality. For example, Jabil was able to increase the number of projects by 400%. Additionally, Vaillant improved first-pass yield by 53%, and Nidec reduced its Cost of Poor Quality (COPQ) by 40%.

Why MBD Outperforms Traditional Methods

The efficiency of MBD lies in its ability to embed semantic 3D annotations within the CAD model. These annotations are understood by downstream software for Computer Aided Manufacturing (CAM) and Coordinate Measuring Machines (CMM), ensuring that all stakeholders in the production process—designers, manufacturers, and inspectors—are aligned. This alignment leads to several benefits.

The first benefit is faster Design-Manufacturing-Inspection Cycles. MBD reduces the need for rework and corrections. The second benefit is overall, there are fewer errors. The embedded information minimizes miscommunication and errors, reducing COPQ. Due to the first 2 points, engineering productivity is typically increased. Teams can focus more on innovation and less on administrative tasks. This is arguably the best possible outcome when dealing with people, and engineering work.

Transitioning from 2D Drawings to MBD

For companies still reliant on 2D drawings, the transition to MBD might seem daunting, but it’s simpler than you might think. If your engineers already know how to create 2D drawings, they can easily transition to MBD. Most organizations see near-immediate benefits in development time, cost, and quality by starting with a single pilot project.

Key elements of MBD include:

Annotation Planes: Define the placement and orientation of details within the model.

3D Annotations: Capture Product and Manufacturing Information (PMI).

Combination States: Organize and clarify 3D annotations for better understanding.

Delivering with Technical Data Packages (TDP)

A common misconception about MBD is that it is entirely “paperless.” While the 3D model becomes the primary source of truth, MBD allows for flexibility, enabling companies to generate drawings when necessary. The primary deliverable in MBD is the Technical Data Package (TDP). This is a comprehensive set of electronic files including the following:

- The model in its native or CAD-neutral format (e.g., STEP AP242)

- Bill of Materials (BOM)

- Requirements, specifications, and schematics

- Quality documentation, such as First Article Inspection (FAI) sheets

The TDP serves as the single source of truth for your engineering definition, streamlining communication and ensuring consistency across the enterprise.

Moving Towards a Model-Based Enterprise (MBE)

Adopting MBD is just the beginning. The ultimate goal is to become a Model-Based Enterprise (MBE), where MBD principles extend beyond engineering into manufacturing, quality control, supply chain management, and more. As an MBE, your organization will benefit from optimized processes, increased efficiency, and greater profitability.

At SPK and Associates, we recognize the importance of staying ahead of the curve but doing so strategically. That’s why we partner with PTC, whose Creo software continually evolves to enhance MBD functionality. Recent updates include:

- Enhanced table creation and import capabilities

- General Profile Tolerances (GPT) for streamlined Geometric Dimensioning and Tolerancing (GD&T)

- Compliance with international standards such as ASME Y14.5 and ISO 1101

- Improved workflows for symbols and surface finishes

- GD&T Advisor support for assemblies

If you’re ready to accelerate your product development and reap the benefits of MBD, SPK and Associates is here to help. As a trusted PTC Partner, we can assist you not only in purchasing Creo licenses at a discount but also in making a smooth transition to Creo or Creo+ from other CAD solutions. Coupled with SPK vCAD, Creo can help support your change to an MBE. Moreover, our consulting or CAD migration services will guide you on your journey to becoming a fully integrated Model-Based Enterprise, ensuring that your organization is positioned for long-term success.

Contact SPK and Associates today to start your MBD journey and unlock the full potential of Creo.