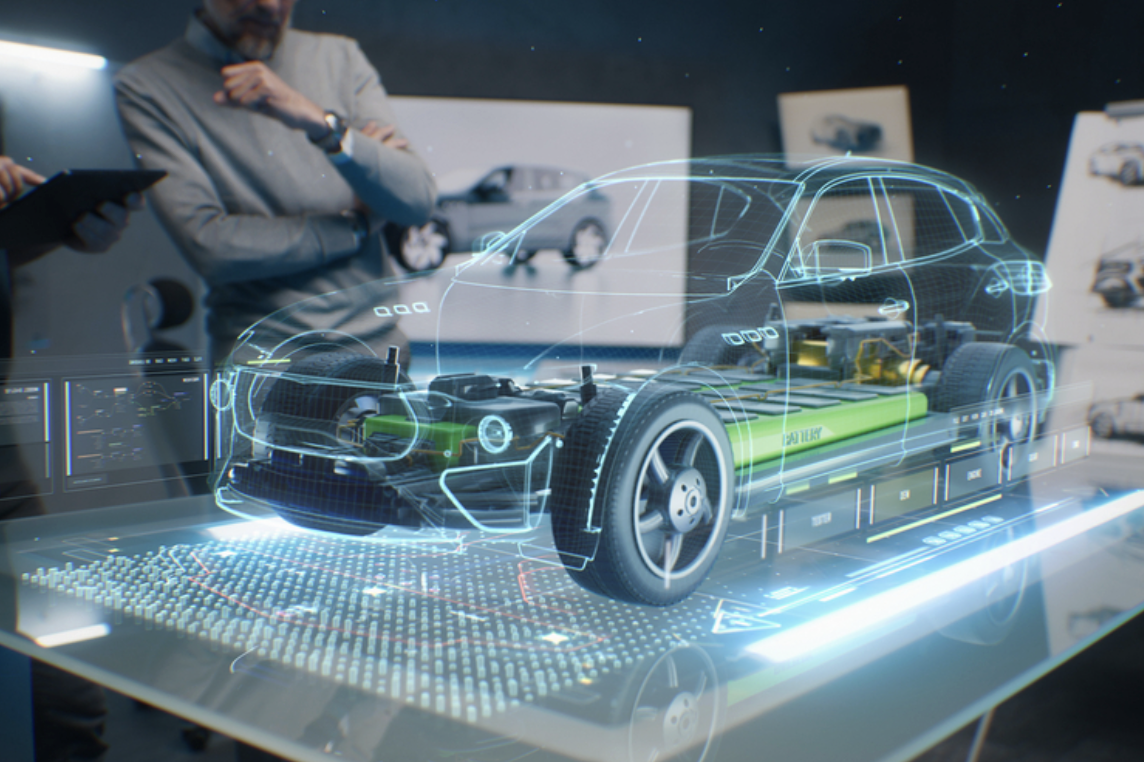

Automotive product development is undergoing one of the most significant transformations in its history. Software-defined vehicles, advanced driver assistance systems, electrification, and increasing regulatory pressure are all factors that are stretching traditional development models beyond their limits. For automotive OEMs, speed to market is no longer a competitive advantage, but a requirement. A connected digital thread can enable this. By integrating hardware and software development across the product lifecycle, automotive organizations can reduce development timelines, lower lifecycle costs, and improve quality at scale.

The Cost of Fragmented Hardware and Software Collaboration

Many automotive organizations still rely on siloed processes, legacy requirements tools, and manual change management workflows. These approaches struggle to keep pace with the increasing complexity of modern vehicles.

Common pain points include:

- Disconnected hardware and software teams working from different systems

- Requirements, tests, and regulations managed in isolation across suppliers

- Changes made upstream that fail to propagate downstream in real time

- Manual traceability and documentation for safety and compliance standards such as ISO 26262 and ASPICE

- Limited reuse of parts and designs due to poor visibility into prior programs

The impact is measurable. Up to 20 percent of excess vehicle development time can be attributed to traceability gaps, unsynchronized changes, and delays in managing complex requirements. These inefficiencies slow validation, increase rework, and extend time-to-market.

PTC’s Proven Success in Automotive Transformation

PTC has worked with leading automotive OEMs and suppliers to address these challenges by transforming how product data flows across the enterprise. Through its Intelligent Product Lifecycle approach, PTC enables a unified product data foundation from requirements through service. Its

integrated configuration and change management lead to better traceability. Additionally, compliance and quality management are embedded into daily workflows. Furthermore, advanced simulation and early digital validation capabilities help reduce physical prototyping. Overall, PTC’s digital thread ensures multidisciplinary collaboration across mechanical, electrical, and software teams.

Automotive customers leveraging this approach have achieved tangible outcomes, including:

- 20 percent reduction in vehicle development timelines

- 3 percent reduction in vehicle lifecycle costs

- 10 percent reduction in total cost of quality

These results demonstrate how digital thread integration directly translates into faster programs and more predictable outcomes.

Synchronizing the Digital Thread With Codebeamer, Windchill, and MBSE

At the core of this transformation is tight synchronization across requirements, testing, manufacturing, and compliance.

Codebeamer provides centralized hardware and software requirements management, traceability, and test orchestration. By connecting requirements to verification and validation activities, teams can identify risks earlier and ensure they are building the right product, correctly.

Windchill delivers the product data backbone that connects engineering, manufacturing, supply chain, and service. It enables parts and assembly rationalization, configuration management, and reuse across platforms. This helps reduce redundant development and control variant complexity.

Model-Based Systems Engineering (MBSE) ties everything together by allowing teams to model system behavior, interfaces, and dependencies digitally. This makes it possible to assess the impact of changes before physical builds. It accelerates validation while reducing costly late-stage surprises.

Together, these capabilities enable:

- Real-time synchronization of requirement changes across the lifecycle

- Automated traceability from R&D through manufacturing and service

- Early digital validation using simulation and model-based design

- Faster compliance reporting through centralized regulatory data and AI-assisted workflows

- Improved supplier collaboration with accurate, up-to-date specifications

Case Study: Automotive OEM Accelerates Development by 20%

The following is an example of PTC solutions in action. An automotive OEM needed to modernize its development environment to support increasing software-defined vehicle complexity. This included ADAS capabilities.

The Challenge

The OEM relied on legacy IT systems that could not scale with growing hardware and software integration demands. Requirements and test management were fragmented, slowing validation and complicating supplier collaboration.

After PTC Solution Implementation

Through a multi-year partnership, PTC helped the OEM:

- Improve agility in managing complex hardware and software requirements across subsystems

- Implement a robust verification and validation model aligned to software-defined vehicles

- Ensure compliance with safety and quality standards

- Enable dynamic communication of requirement and specification changes to suppliers

Impact

The OEM achieved a 20% reduction in vehicle development time. Additionally, they improved collaboration, traceability, and confidence in regulatory compliance.

Reducing Time to Market with PTC

As vehicle complexity continues to grow, automotive OEMs and suppliers must adopt a connected digital thread. By integrating Codebeamer, Windchill, and MBSE within PTC’s Intelligent Product Lifecycle, organizations can reduce time-to-market, lower costs, improve quality, and meet stringent regulatory demands. If you are interested in implementing PTC’s digital thread for your automotive team, contact us.