Cutting down quality-related costs without compromising product performance can be a difficult balancing act. Improving efficiency, eliminating waste, and ensuring compliance can all exist in tandem when engineering teams implement best practices. Utilizing defect prevention, lean manufacturing, and automation can help these teams succeed. Additionally, leveraging premier PLM and CAD tools such as PTC’s Windchill and Creo can further streamline processes. Here’s how your team can enhance compliance, reduce risks, and lower quality-related expenses.

Defect Prevention: Stopping Issues Before They Start

Defect prevention is a proactive strategy that identifies and eliminates potential defects before they occur. This approach minimizes costly rework, enhances product quality, and boosts customer satisfaction.

Key Techniques to Prevent and Eliminate Defects

- Review and Inspection: Conduct regular design reviews and inspections to catch potential issues early.

- Set Checkpoints: Establish quality checkpoints throughout the development cycle to ensure early issue detection.

- Defect Analysis: Track and analyze defects from previous projects to identify common trends.

- Continuous Improvement: Use feedback from past projects to refine development processes.

- Root Cause Analysis: Investigate defects thoroughly to prevent recurrence by addressing their underlying causes.

How Windchill and Creo Help Prevent Defects

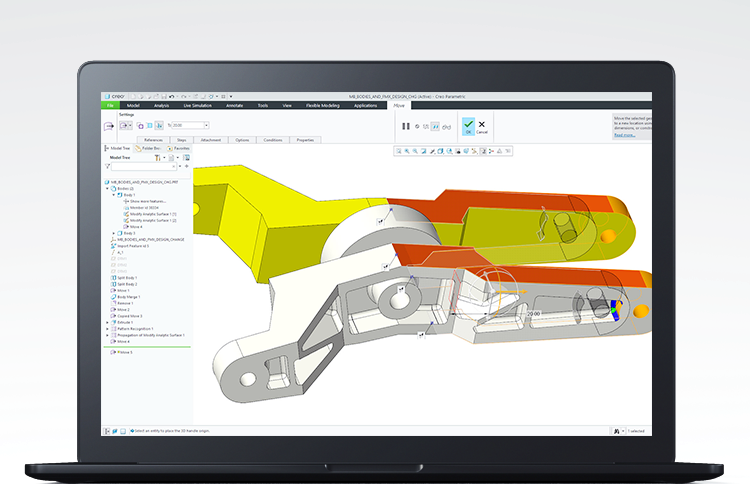

Utilizing PTC Windchill’s quality, risk, and compliance management capabilities helps teams enforce standardized quality processes that prevent defects. In addition to this, enterprise change management in Windchill ensures seamless collaboration between engineers, suppliers, and manufacturers. This prevents miscommunications that can often lead to defects. Creo’s simulation tools allow engineers to test product designs under real-world conditions before prototyping. This reduces issues post-production. All of these features aim to improve quality and in turn, they lessen (or eliminate) costly rework.

Applying Lean Manufacturing to Product Development

Lean manufacturing is a methodology focusing on maximizing value and minimizing waste. When applied to product development, it streamlines workflows, ensuring efficiency.

Lean Principles and Their Application

These are the following Lean Principles:

- Identify Customer Value: Focus on building products that address customer needs while maintaining high quality.

- Map the Value Stream: Identify inefficiencies and eliminate waste in design, development, and manufacturing processes.

- Create Continuous Flow: Reduce bottlenecks and ensure a seamless transition between design, testing, and production.

- Establish a Pull System: Base production decisions on customer demand to reduce overproduction and inventory waste.

- Continuous Improvement: Encourage ongoing refinement in design and production processes to improve efficiency and reduce costs.

How Windchill and Creo Support Lean Manufacturing

Creo’s generative design capabilities automatically optimize components for performance and material usage. This feature helps reduce unnecessary waste. Additionally, Windchill’s digital thread integration connects design, engineering, and manufacturing teams to ensure a seamless flow of information. This helps engineers reduce errors and rework as well as continuously improve. Windchill’s supplier and product data management capabilities also ensure that all stakeholders have access to accurate, up-to-date information. These features improve collaboration and reduce lead times. By optimizing material use and improving collaboration, developers can work together to create products without wasting costly materials.

Leveraging Automation to Reduce Costs and Increase Efficiency

Automation in product development accelerates workflows, minimizes human errors, and improves overall productivity. By automating repetitive tasks, engineering teams can focus on innovation and high-value work.

Key Areas Where Automation Reduces Quality Costs

- Design Automation: Use Creo’s Parametric Modeling to automatically adjust designs based on predefined constraints, saving time and reducing errors.

- Testing and Quality Assurance: Implement automated testing frameworks to identify defects early.

- Production Planning: Use data-driven automation to optimize schedules and resource allocation.

- Requirement Gathering: Automate feedback collection and analysis to ensure products align with customer needs.

- Data Analysis: Leverage AI-driven insights to improve product performance and anticipate potential failures.

How Windchill and Creo Enhance Automation

Creo’s AI-powered design tools automate iterations, ensuring optimal designs with minimal manual input. Additionally, its additive manufacturing capabilities streamline prototyping by automating 3D printing setups and material usage calculations. In addition to this, Windchill’s secure collaboration and change management features automate documentation and approvals, reducing administrative overhead. By using automation, development teams can create and approve designs faster and test products in a digital environment. This eliminates the costs of slow production and physical prototypes.

How SPK and Associates Can Help Reduce Quality Costs

At SPK and Associates, we specialize in implementing and optimizing Windchill and Creo for your unique business needs. We help product engineering teams improve efficiency, reduce risks, and ensure compliance. Here’s how we can support your business:

- Windchill Implementation and Customization: We tailor Windchill’s PLM capabilities to fit your specific industry and regulatory requirements.

- Creo Training and Support: Our expertise in Creo helps your team maximize the benefits of advanced design, simulation, and manufacturing tools.

- Regulatory Compliance Consulting: We assist with compliance strategies to reduce long-term risk and associated costs.

- Process Automation and Digital Transformation: We integrate automation solutions that streamline design, collaboration, and production workflows.

By leveraging SPK’s expertise with PTC tools, your business can lower quality costs and accelerate time-to-market.

Ready to Reduce Quality Costs?

Reducing costs is critical to maintain a competitive edge in product development. By balancing cost efficiency with quality management, organizations can produce high-quality products within a budget. Implementing defect prevention strategies, lean manufacturing principles and automation can help reduce waste and improve efficiency. With the power of PTC Windchill and Creo, and an SPK expert by your side, businesses can achieve significant cost savings while maintaining product excellence. If you are ready to optimize your product development processes, contact SPK and Associates.