When developing products, design collaboration is critical to reducing miscommunication and improving design quality. Engineers and designers must work seamlessly, sharing ideas in real time to ensure that everyone is always working with the latest data. PTC’s Creo+ represents a paradigm shift in engineering collaboration. While expanding upon Creo’s typical collaboration tools, Creo+ enables teams to innovate faster by offering real-time changes to the product design workflow. Let’s explore how PTC is transforming collaboration for engineering teams.

Collaborating with Creo

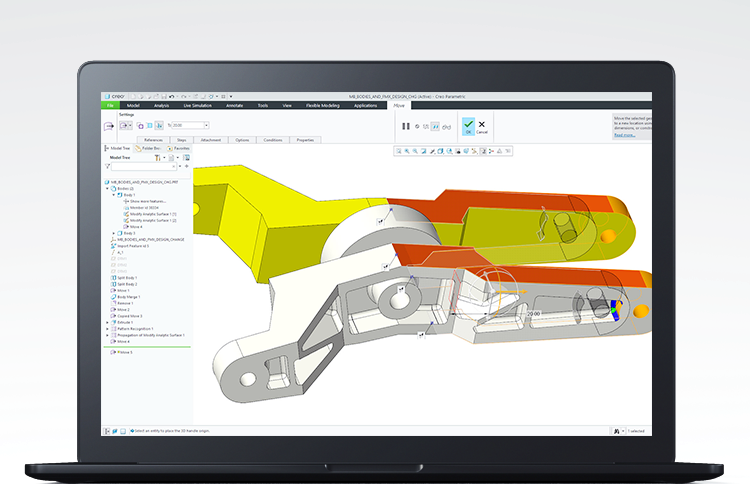

While PTC offers a SaaS-based version of Creo, (Creo+), the original CAD program offers many features for collaboration. Firstly, Creo supports concurrent engineering, which allows teams to work on different aspects of a product simultaneously rather than sequentially. In addition to this, its parametric and direct modeling capabilities allow for real-time updates, ensuring that changes in one area are reflected across the entire design. Creo also offers built-in design review tools that allow teams to provide feedback directly within the CAD model. Users can mark up designs, add annotations, and suggest modifications in an organized way. This helps reduce miscommunication and lengthy review cycles.

Furthermore, Creo supports collaboration across mechanical, electrical, and software engineering teams. Software teams can even leverage model-based systems engineering (MBSE) methodologies to integrate software requirements into the design process. Creo’s integration capabilities allow Windchill to automatically reflect modifications to the model in the Bill of Materials (BOM). Additionally, Windchill allows design teams to collaborate on data in real time.

Empowering Design Collaboration in Real Time with Creo+

Traditional product design workflows often rely on asynchronous collaboration, meaning engineers work on different versions of a design separately. This workflow often leads to delays and miscommunications due to the many different versions. It can take days for engineers to receive the proper feedback, causing costly design conflicts. Creo+ eliminates these barriers by allowing multiple users to work together on a design in a single, secure cloud environment. This means no longer waiting for design files to be passed around via email or checking for the latest version manually. Instead, engineers can see changes happening in real-time and provide immediate input. It is just like collaborating in a shared document but for complex 3D models.

Key Features of Creo+ for Seamless Collaboration

Creo+ is packed with features that streamline collaboration and design management, helping teams work smarter and faster:

- Version Synchronization – Say goodbye to version control headaches. Automatic synchronization ensures all collaborators work on the latest design iteration.

- Conflict Prevention – Only one user at a time can modify a specific part, reducing conflicts and ensuring smooth collaboration.

- Branching Capabilities – Quickly explore design variations and merge them back into the main model effortlessly.

- User Notes & Notifications – Keep teams aligned with built-in notifications and annotation capabilities.

- Scalable Collaboration – Teams can create multiple collaboration sessions across different assemblies and components.

These features enable faster decision-making, fewer errors, and improved design quality, ultimately shortening development cycles and reducing costs.

Importance of Design Collaboration

The features offered by Creo and Creo+ are great, but why are they important? Engineers’ ability to collaborate during the design process not only reduces errors but improves product quality. Fewer errors also result in a quicker time to market. Collaboration also fosters innovation and allows engineers to problem-solve together. Furthermore, when everyone works together, it helps ensure compliance needs are met and that resources are optimized.

The Future of Engineering Collaboration with Creo

Creo’s concurrent engineering, collaborative review, and integration capabilities allow for a seamless design phase. The shift to SaaS and real-time collaboration in Creo+ expands upon these capabilities, redefining how engineers work together. By enabling seamless teamwork, better version control, and more structured communication, Creo+ helps design teams eliminate inefficiencies and accelerate product development.

Are you ready to supercharge your engineering collaboration? Contact our experts to see how PTC products can take your design process to the next level.