As product complexity and pressures to achieve a faster time-to-market both increase, developers are seeking new ways to achieve efficient operations. Streamlining product development while maintaining high quality can be challenging. However, approaches like Component-Based Engineering (CBE), enable organizations to develop products more efficiently by leveraging pre-designed, reusable modules. Let’s explore the benefits of component-based engineering and modular design with PTC Creo.

Understanding Component-Based Engineering

Component-Based Engineering is a product design approach that emphasizes the reuse of standardized components. Rather than designing each element from scratch, engineers integrate pre-existing modules that have been tested and validated. This simplifies the creation of complex products. Additionally, it fosters efficiency and reliability while reducing development time and costs.

CBE is widely used in industries such as automotive, aerospace, medical devices, and consumer electronics. These industries require design consistency and rapid production cycles to get safe products to market quickly. Standardizing components allows companies to maintain high-quality standards while accelerating product development. In addition to this, CBE promotes collaborative engineering. Common component libraries and design standards allow teams across different disciplines to work together seamlessly.

Modular Design: Accelerating Product Development

Modular design is a fundamental principle of Component-Based Engineering that allows engineers to build complex products from standardized components. By using pre-developed modules, companies can reduce redundancy, shorten production cycles, enhance flexibility, and simplify maintenance. Instead of designing every part from scratch, engineers integrate existing components. This helps minimize duplication of effort and ensures consistency. Reusing established components significantly cuts down development time, enabling faster prototyping and deployment. In addition to this, modular systems are flexible, allowing for easy updates and variations. They support customization without requiring a complete redesign. Standardized components are also easier to replace and upgrade. This reduces the need for continuous maintenance and improves product longevity.

Component-Based Engineering and Modular Design with Creo

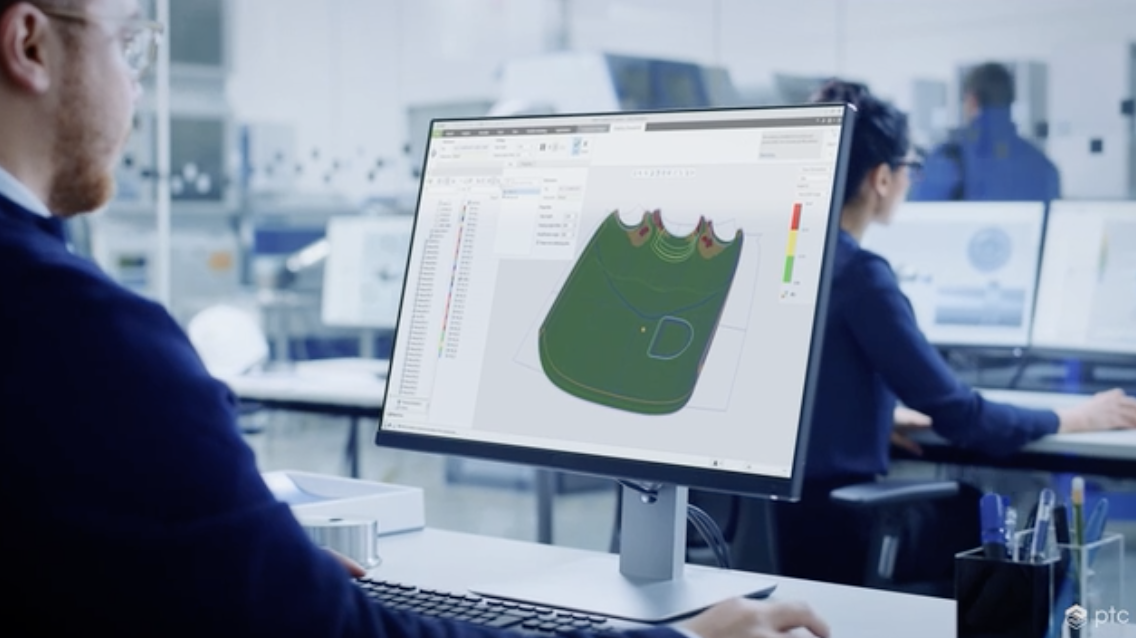

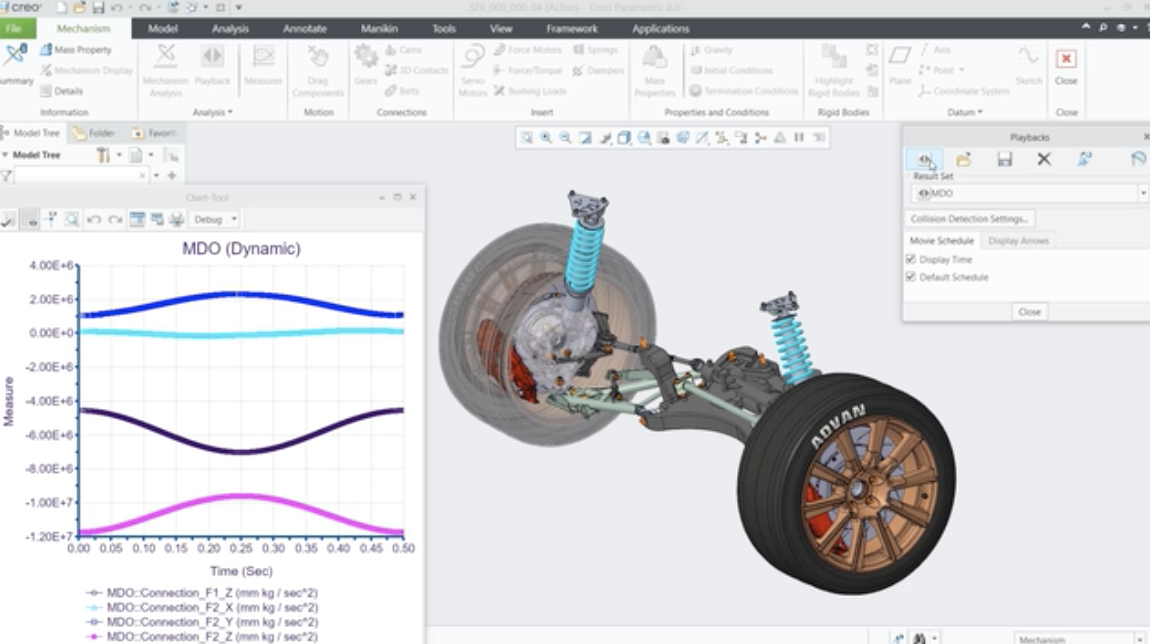

PTC Creo is a powerful CAD tool that offers extensive Component-Based Engineering and modular design capabilities. Creo Parametric is PTC’s main 3D CAD software that enables parametric modeling. This software enables engineers to create and manipulate designs with precision. Unlike traditional CAD software, Creo Parametric updates all related parts and assemblies when one part is altered. This approach enhances efficiency and ensures design consistency which is particularly important in Component-Based Engineering. This is because CBE requires standardized parts to be adapted across multiple product variations.

Creo Parametric includes features like automation, simulation, generative design, and integrated manufacturing capabilities, which empower engineers to accelerate innovation. A standout feature is the Component Interface Command. This enables predefined connection points to ensure accurate alignment and reduce manual adjustments. It promotes standardization and reusability, allowing engineers to apply consistent interfaces across multiple designs. Additionally, it supports automated component placement, accelerating design iterations. This feature also facilitates scalable and flexible design, making it easy to adapt products for different configurations. When integrated with Creo Parametric and Windchill PLM, the Component Interface Command improves collaboration by maintaining interface definitions across teams.

Benefits of Component-Based Engineering with Creo

Adopting a component-based approach with Creo offers significant advantages. Firstly, Creo’s capabilities eliminate redundant work and streamline design iterations. This allows companies to bring innovative products to market quickly. Reusing tested and validated components also minimizes design flaws. This leads to more reliable and high-performance products. In addition to this, CBE in Creo helps organizations save money. Reducing design and manufacturing redundancies lowers development costs and optimizes resource allocation. Furthermore, modular design enables organizations to scale their product lines efficiently. It supports future expansion and adaptation to market needs.

Staying Competitive with Modern Design Principles and Tools

Component-Based Engineering, (supported by modular design principles), is transforming the product development sphere. By leveraging reusable components, companies can significantly enhance efficiency, flexibility, and innovation while maintaining high product quality. With the help of tools like PTC Creo, organizations can embrace CBE and stay competitive. If you would like to meet the demands of modern engineering challenges, contact us today to get started.