When buying a vehicle, one of your top priorities is likely that your purchase is reliable. A car that “performs” well sells well. In addition to performance, the automotive industry thrives on innovation and consumer satisfaction. With intense competition from both Original Equipment Manufacturers (OEMs) and aftermarket suppliers, automotive manufacturers must consistently deliver high-quality, visually appealing products to maintain market leadership. With 3D CAD Solution Creo, these companies can navigate high demands from concept to production.

Designing Successful Vehicles

In the automotive world, good-looking products sell better. The concept design stage is critical to creating vehicles and components that capture consumer appeal. While they must look nice, these designs must also meet performance and quality benchmarks. Creo enables companies to enhance aesthetics with features like Freestyle Design and Parametric Surfacing. These features allow designers to create high-quality freeform and stylized geometry that aligns with consumer preferences.

In addition to this, Creo’s tools like Design Exploration and Generative Design allow for the rapid prototyping of multiple designs. This helps evaluate design concepts to ensure the final product is innovative but feasible. Utilizing this feature minimizes the risk of failed product launches. Lastly, photorealistic renderings from Render Studio and AR Design Share allow all stakeholders to agree upon a concept in the early stages. The ability to quickly share designs allows organizations to align the design with brand reputation, aesthetics, and performance goals.

Refining Automotive Designs

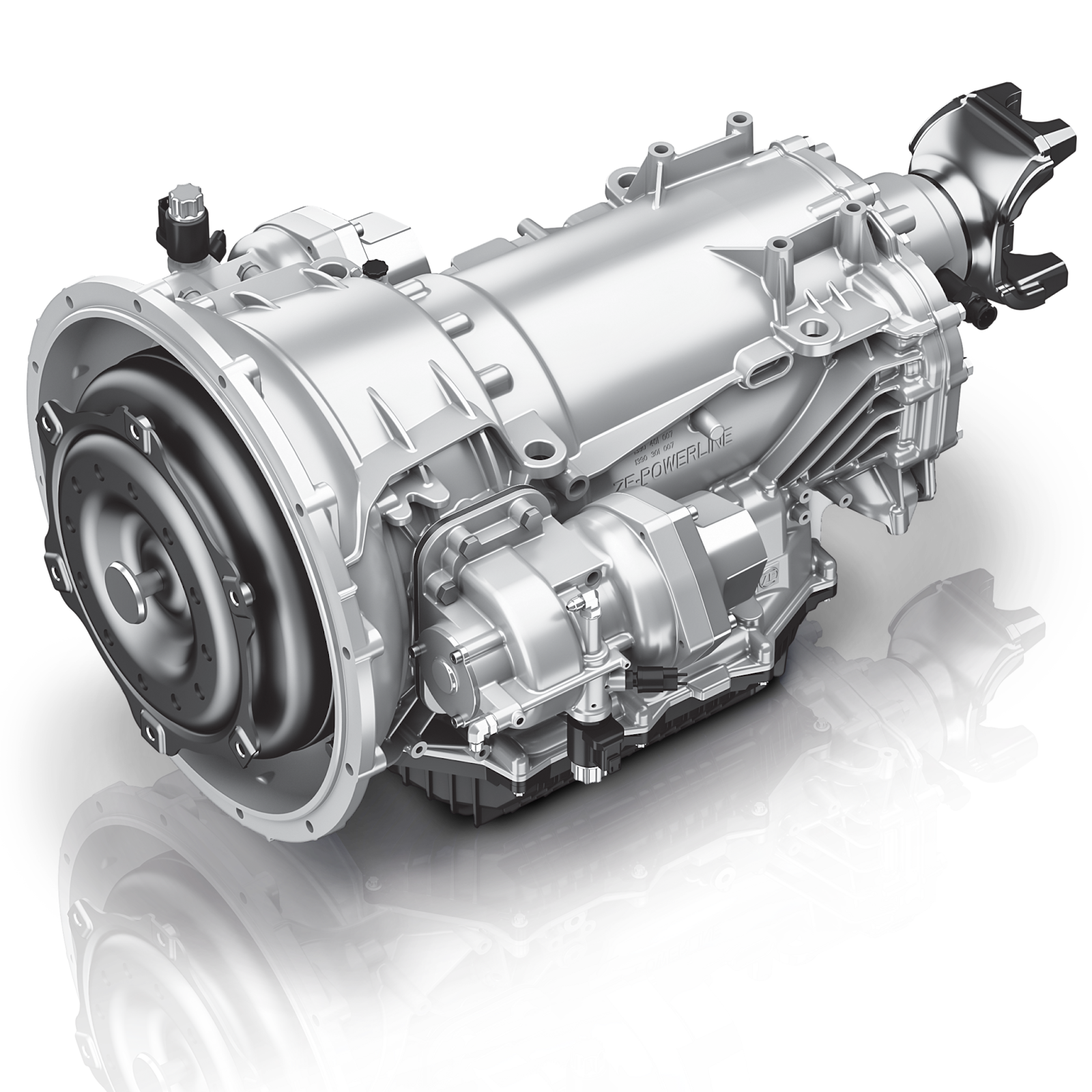

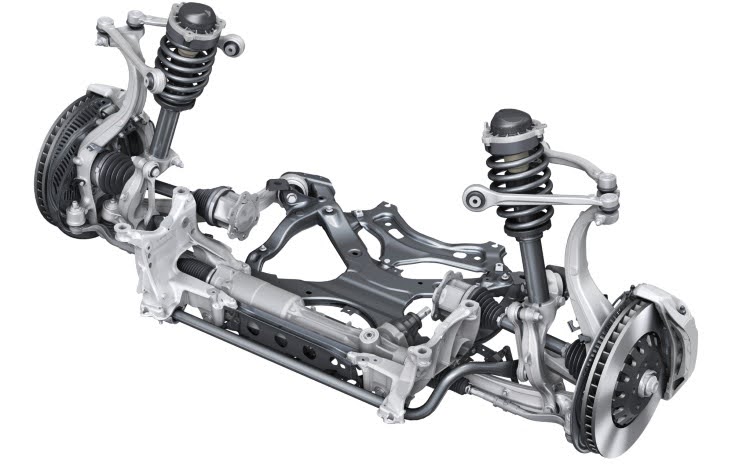

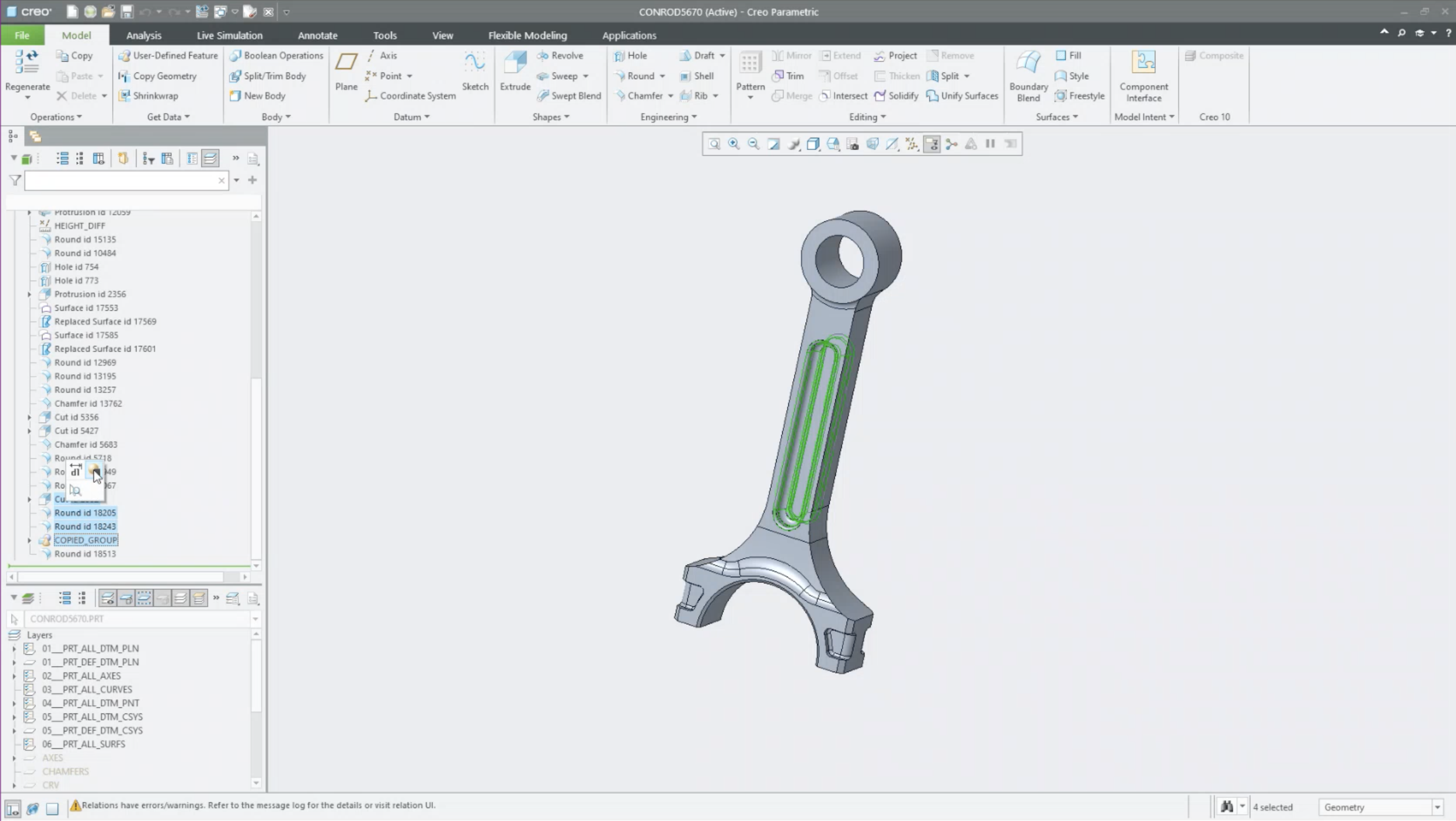

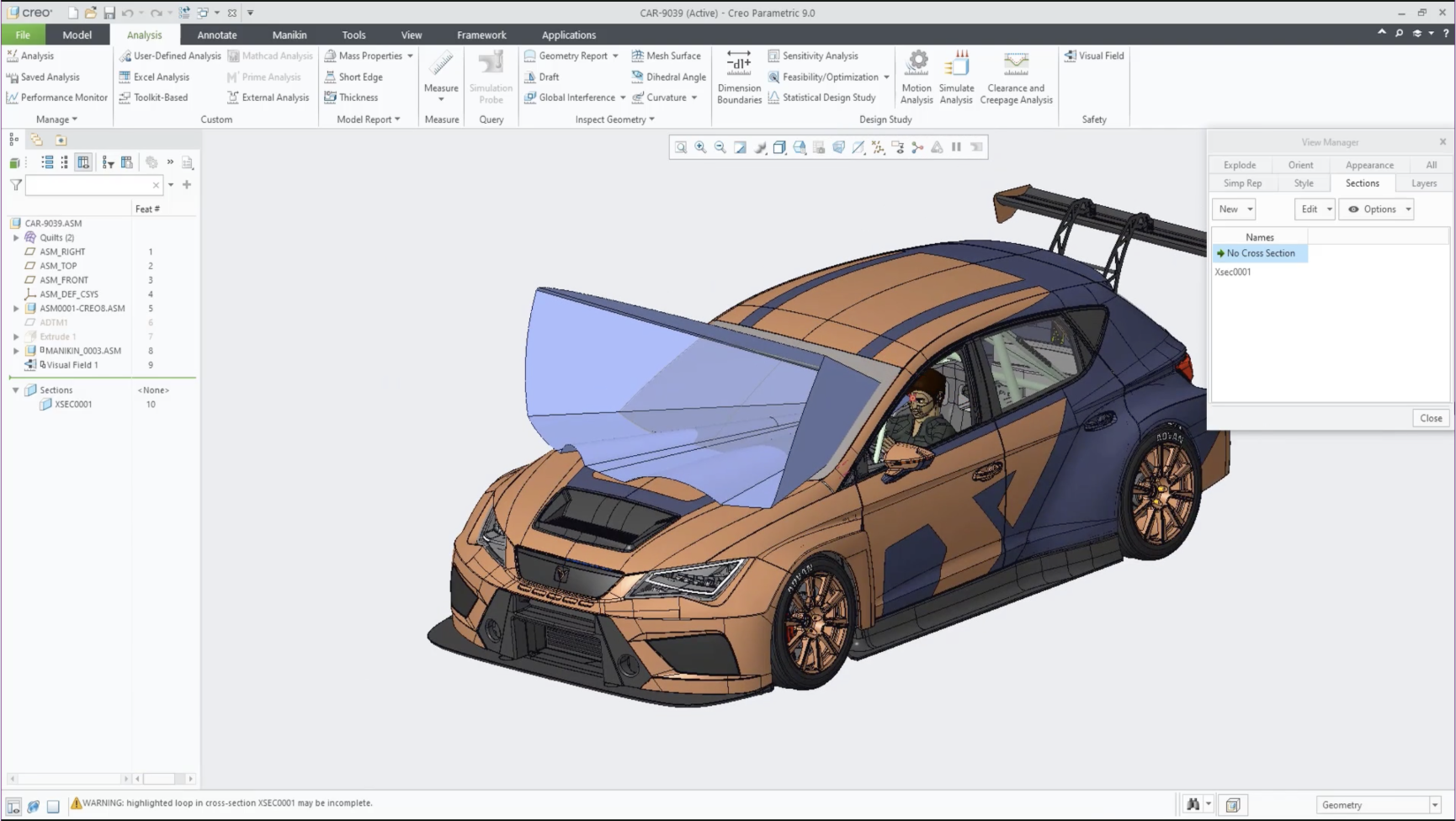

Once a concept is finalized, automotive manufacturers shift to detailed design. In this stage, the focus is on precision, performance, and manufacturability. Creo excels in this phase by offering tools that streamline the process. Its Interactive Surface Design and Behavioral Modeling features allow engineers to refine designs, optimizing for performance and quality. Tools like Advanced Assembly and Mechanism Design enable teams to manage large assemblies with many parts. Furthermore features like Creo Simulation Live and EZ Tolerance Analysis provide real-time insights that help designers validate and optimize their work. This ensures accuracy, fit, and functional performance.

Testing Vehicle Designs with Simulation

Product quality, durability, and safety are non-negotiable when producing vehicles. Keeping customers safe is the automotive manufacturer’s number one priority. Fortunately, Creo offers a robust suite of simulation tools to validate designs. Simulation Live and Creo Ansys Simulation enable real-time analysis of structural, thermal, and vibration aspects. This reduces reliance on late-stage prototypes by testing them in a simulated environment.

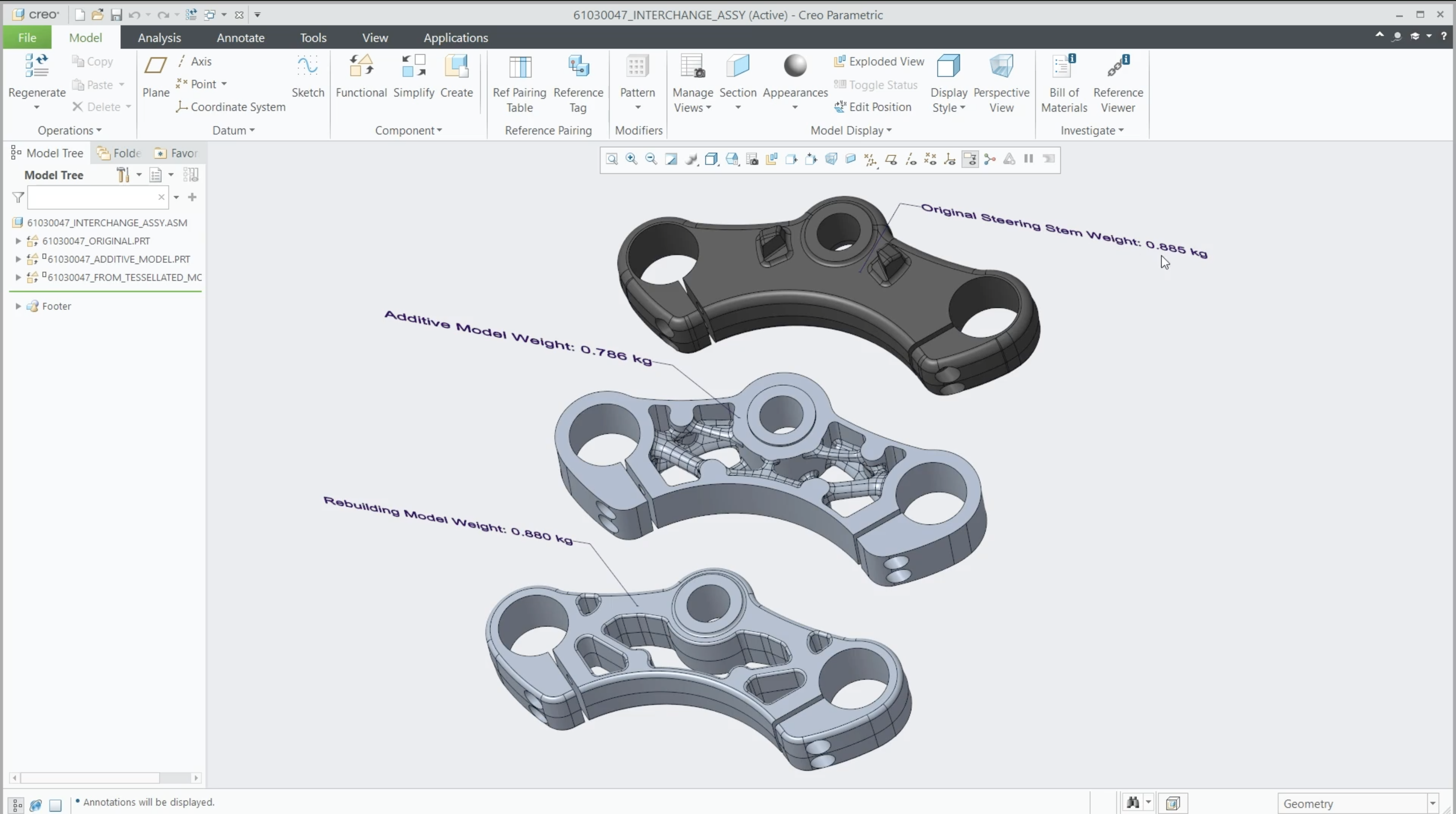

In addition to this, Generative Design and mechanism dynamics tools can be used to refine designs for optimal weight, strength, and functionality. This is vital to know before manufacturing a prototype. Creo’s advanced capabilities such as fatigue, flow, and injection molding analysis ensure products meet rigorous performance and safety standards. Overall, Creo’s simulation capabilities can help identify and resolve design flaws early and reduce physical prototyping costs.

Automotive Manufacturing with Creo

A smooth transition from design to manufacturing is critical to accelerating time-to-market for automotive manufacturers. Creo’s manufacturing capabilities streamline production with Integrated NC Machining Solutions that support everything from prismatic milling to 5-axis high-speed machining. These features ensure complex geometries are efficiently produced. Creo also offers additive manufacturing tools that can create optimized components. These components such as lightweight lattice structures can be used to make components lighter while maintaining their strength. These structures can often help improve fuel efficiency and battery pack efficiency. Additionally, lattice structures can absorb impact better than traditional parts. Creo’s automated tool design features like Moldbase Design and Progressive Die Design speed up the creation of production tooling. These features ensure high-quality outputs.

Transforming the Automotive Industry with Creo

Creo’s integrated solutions are revolutionizing the automotive industry by enabling weight reduction, improving fuel efficiency, and accelerating innovation. Generative design, for example, empowers manufacturers to achieve new levels of component design optimization. Furthermore, simulation-driven approaches mitigate risks and ensure reliability. As Mark Stewart, IT Director at Penske Racing, noted: “PTC solutions allowed us to generate our latest race car in 8 months, where it used to take us 2 years.”

Revolutionize Automotive Design with Creo

Creo stands out as the preferred tool for automotive manufacturers by offering tools for collaboration, end-to-end design and manufacturing capabilities, and a unified platform. With Creo, automotive companies can drive design innovation, enhance performance, and deliver superior products that resonate with consumers. From concept design to manufacturing, Creo ensures every phase of development is efficient and accurate. If you’re ready to take your automotive designs to the next level, contact us today to transform your product development process.