Compliance with environment, health, and safety (EHS) regulations is critical for organizations across fields. This is not just due to the importance of creating safe products, but also due to the financial benefits. The inability to compete in markets with increasingly comprehensive and strict EHS requirements directly reduces revenue. Companies that neglect safety not only face fines and legal costs but also risk recalls, reputational damage, and the loss of access to regulated markets. In this blog, we’ll explore the financial impact of poor health and safety decisions and show how PTC’s digital thread can help manufacturers stay compliant, reduce risks, and unlock revenue growth.

The Revenue Impact of Poor Health and Safety Practices

Failure to address safety leads to accumulating costs such as:

- Fines: For organizations in the U.S, OSHA violations can result in penalties up to hundreds of thousands of dollars per violation, creating immediate and measurable financial hits.

- Civil Lawsuits: Settlements from workplace injuries range from $100,000 to $10 million, depending on severity.

- Production Shutdowns: An inspection by a health organization such as OSHA can halt operations for a week or more, resulting in lost production revenue that could total millions.

- Insurance Increases: Poor safety performance raises premiums, reducing profitability long-term.

- Reputation Loss: Negative headlines can erode trust with customers and employees, leading to churn and higher recruitment costs.

The combination of these financial risks creates a total potential loss stretching into tens of millions. This is not even including lost access to markets where strict regulations prevent non-compliant companies from competing.

Real-World Examples of Revenue Loss

The following examples display how non-compliance leads to lost revenue.

Automotive Software Safety Risks

As infotainment systems evolved into complex software platforms, vulnerabilities created safety hazards. Failure to manage these risks leads not just to recalls, but to barred entry into safety-regulated markets.

Medical Device Data Gaps

Poor information quality, lack of version control, and disconnected systems can result in non-compliance with FDA regulations. This results in costly recalls, delays in approvals, and blocked sales in critical markets.

Electronics and E-Waste Regulations

Companies unable to meet strict recycling and sustainability standards face exclusion from European markets, forfeiting billions in potential revenue.

Industrial Equipment and Paper-Based Processes

Manual processes often result in errors and injuries. Defective products, rework, and safety hazards increase COPQ (Cost of Poor Quality) and lead to long-term revenue erosion.

How the PTC Prevents Revenue Loss

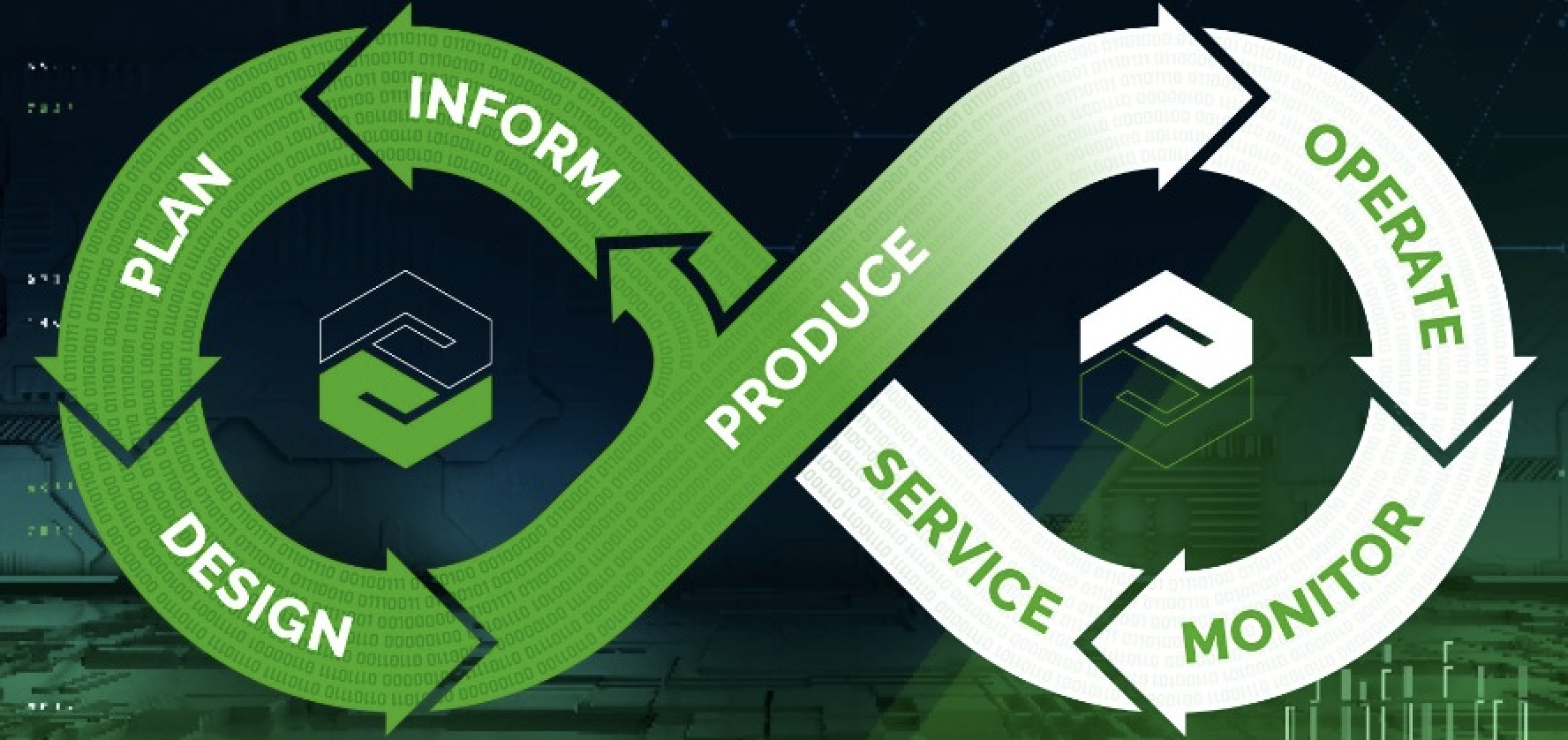

The PTC Value Roadmap directly addresses these challenges by embedding safety, compliance, and quality into every phase of the product lifecycle. Through traceability, validation, and risk management, companies can reduce exposure to financial and reputational risks.

PTC recommends the following:

- Trace & Validate: Ensure requirements, risks, and quality data flow seamlessly across the lifecycle. This reduces recall rates and compliance gaps.

- Risk & Reliability Management: Identify hazards early and mitigate risks before they become revenue losses.

- Change Tracking: Use Engineering Change Orders (ECOs) to improve product safety and performance efficiently, reducing cycle times and avoiding delayed launches.

- Test Management: Continuously validate product design for safety and regulatory compliance.

By aligning these processes within the digital thread, manufacturers improve Mean Time Between Failures (MTBF) and lower Cost of Poor Quality (COPQ).

PTC Tools for Regulatory and Safety Management

Along with the suggestions, PTC offers the proper tools to achieve compliance with health and safety regulations.

ServiceMax Core

ServiceMax Core integrates job safety assessments, near-loss reports, and regulatory data directly into work orders. This integration helps organizations minimize downtime, reduce safety risks, and extend asset lifecycles. By embedding compliance and safety practices into everyday operations, ServiceMax Core creates a more resilient and reliable service environment.

PTC Modeler

PTC Modeler supports system and software modeling through recognized standards such as UML, SysML, and UAF. By using these frameworks, teams can design safety into products from the outset, improving overall reliability and reducing costly rework later in the development cycle. This structured approach ensures that critical systems are modeled with compliance and efficiency in mind.

Codebeamer

Codebeamer provides essential tools for managing requirements, risks, tests, and issues. It is indispensable for regulatory compliance in complex industries such as medical devices and automotive electronics. Its end-to-end traceability enables teams to demonstrate compliance, manage risks proactively, and streamline audits. The ALM solution ultimately supports faster and safer product development.

Creo

PTC’s CAD solution, Creo, enables robust product design and simulation, embedding safety and compliance considerations at the engineering stage. By integrating advanced modeling and validation tools, Creo allows engineers to detect potential issues early and design products that meet both performance and regulatory standards. This reduces development costs and helps bring compliant products to market faster.

Windchill

Windchill delivers enterprise-grade PLM capabilities, including change management, traceability, and audit readiness. By centralizing product data and processes, Windchill ensures regulatory adherence across the entire supply chain. Its ability to manage complex configurations and provide visibility into compliance requirements makes it a cornerstone for organizations seeking to maintain both innovation and accountability.

Together, these tools create a closed-loop system that turns compliance from a cost burden into a competitive advantage.

Preventing Revenue Loss with Health and Safety Compliance

Poor health and safety practices aren’t just compliance risks, they’re revenue killers. From fines and lawsuits to market exclusion and reputation loss, the cost of non-compliance can cripple even established manufacturers. The PTC Value Roadmap, powered by its digital thread and suite of tools, helps organizations proactively manage safety, reduce risk, and protect revenue. In an era of increasing regulatory scrutiny, the companies that thrive will be the ones that treat health and safety not as an obligation, but as a strategic growth driver. If you are interested in exploring how PTC can aid your organization, contact our experts regarding licensing and implementation.