Whether you are in the tech industry or not, you’ve likely heard the term, Software-as-a-Service (SaaS). SaaS is making a shift from being optional, to essential for many businesses due to the flexibility, security, scalability, and improved collaboration it provides. More recently, CAD and PLM programs have started adopting SaaS, causing a shift in the manufacturing and industrial industries. Let’s explore how the benefits of SaaS are causing this shift.

What is SaaS?

Before we dive into how it’s changing the industry, let’s establish what SaaS is. Software-as-a-Service is a subscription-based software distribution model in which users purchase applications from a third party and renew their purchase (typically monthly or annually). This subscription provides users with a continuously maintained software product with automatic updates. SaaS applications are commonly hosted on the cloud, with no need for installations. Common SaaS applications include Google Workspace, Slack, Zoom, Microsoft Teams, Jira, and Mailchimp.

SaaS applications should not be confused with cloud-native or on-premise applications. Cloud-native refers to applications that are developed exclusively for the cloud, making cloud-computing their main goal. On-premise applications on the other hand are applications that are installed. They must be maintained and updated at the same location that they were installed. A major difference between on-premise and SaaS applications is the responsibility of upkeep on-premise apps falls on the end user rather than the seller.

How SaaS is Transforming Manufacturing

While simple SaaS has been a part of our daily lives for years through things like email, modern SaaS applications were lagging behind. For decades, workers could work remotely, but despite improvements in internet speed and online infrastructure, organizations were hesitant to fully embrace hybrid or remote workflows. These actions led companies to continue to keep on-premise software implementations. Then the pandemic hit, shifting the conversation from “can remote work actually work?” to “I need remote work to work right now.”

Now, modern SaaS applications are altering the manufacturing industry. The more businesses embrace SaaS, the more they can utilize remote work. Utilizing remote work has been proven to positively impact employee retention and talent acquisition. In a field where specialized workers can be scarce, this is a big advantage. Before SaaS solutions, organizations would have to make major investments with no real level of remote work being possible. Now, remote work is the norm for many companies.

Financial Benefits of SaaS

The shift to SaaS isn’t solely about enhancing employee culture and well-being. There are significant financial benefits as well. While it’s difficult to make a broad statement like “SaaS saves money” due to numerous variables, it’s clear that the costs of SaaS solutions vary widely among vendors. Additionally, many SaaS vendors are publishing their total cost of ownership in comparison to the cost of managing and operating infrastructure to support the software. The investment costs, training expenses, and potential disruption time indicate that SaaS isn’t inherently cheaper or more expensive than traditional on-premises solutions without further consideration.

However, this analysis often overlooks the impact on employees’ time, particularly within IT departments. When asked whether their IT teams spent more resources maintaining operations (upgrading software, managing hardware, etc.) or facilitating new business strategies, nearly 70% of organizations indicated the latter. This suggests that highly specialized and well-paid IT professionals often act as digital janitors, constantly ensuring essential functions continue smoothly. Given the extent of business conducted digitally today, it is impractical to use such valuable talent solely for maintaining the status quo. IT roles have evolved beyond mere custodianship.

IT Benefits of SaaS

As mentioned before, IT workers often spend time maintaining operations such as managing hardware and upgrading software. With SaaS, this issue is eliminated, allowing IT staff to spend their time facilitating business strategies instead of cleaning up messy applications. SaaS allows IT departments to become more active and engaged in ongoing digital transformation efforts. By saving the IT department time, SaaS can also save businesses money, even with the additional cost of use.

CAD and PLM in a SaaS World

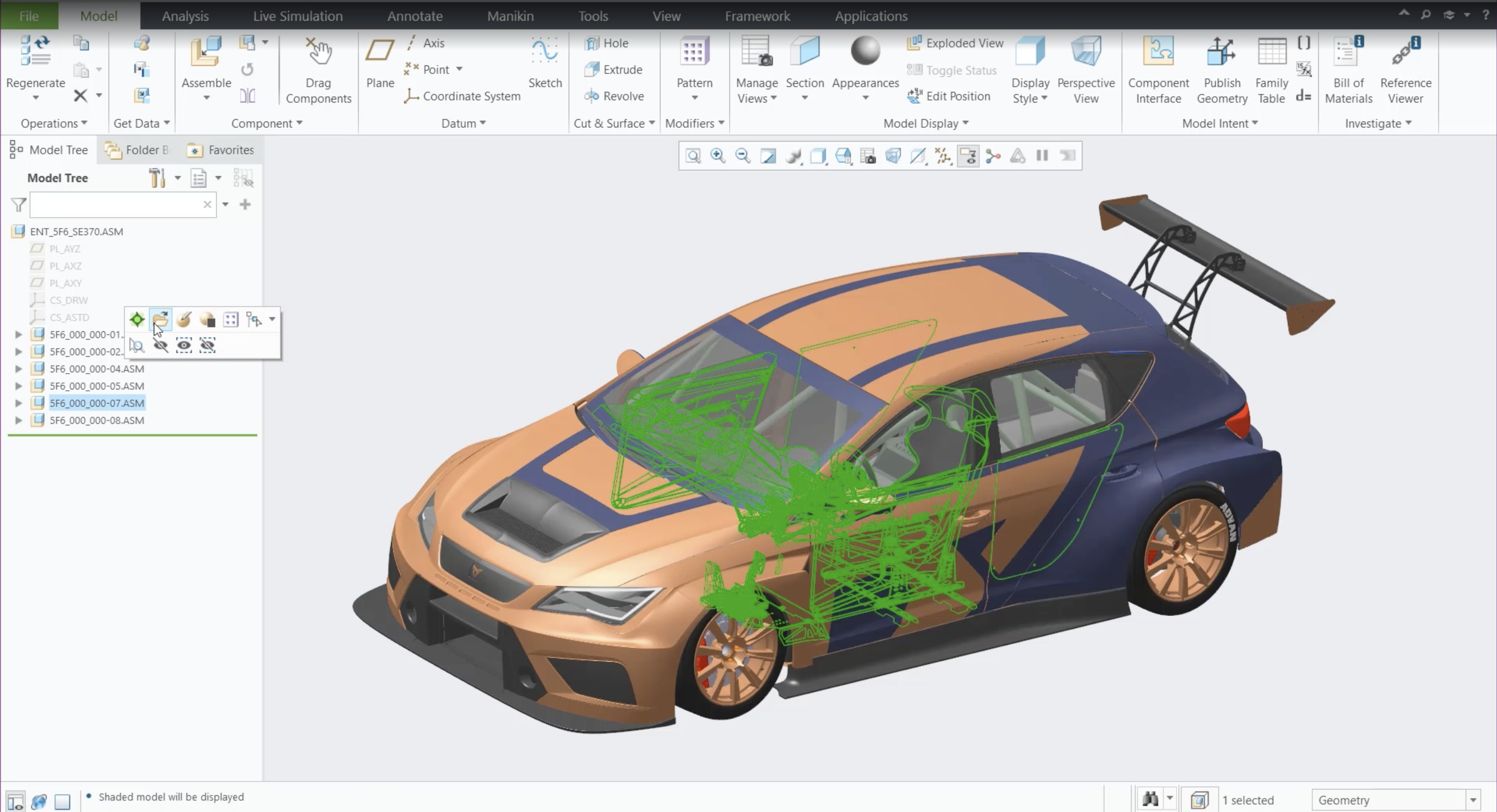

SaaS’s success in other aspects of manufacturing has led many CAD and PLM users to consider SaaS over on-premise applications. Online infrastructure improvements have made CAD design and PLM management possible in the cloud with high levels of computing power. It is not just possible, but now common to execute large amounts of computing in the cloud. While on-premise solutions like Creo and Windchill still provide amazing results, SaaS applications like SPK vCAD and Windchill+ provide fast production and increased remote collaboration.

Windchill+ leverages the benefits of SaaS architecture to provide enhanced capabilities while keeping all of Windchill’s original features. It allows users to expand functionality and adopt new features instantly, ensuring that software deployment does not interfere with ongoing innovation. Additionally, Windchill+’s SaaS model has built-in security measures and compliance features. Overall, Windchill+ enables organizations to simplify PLM while driving forward digital transformation.

The Future of SaaS in Manufacturing

With applications like Windchill+ on the market, it is easy to see the future of SaaS for the manufacturing industry is bright. SaaS offers amazing scalability, security, and compliance features, allowing employees to produce great work from anywhere. If you would like to get started with Windchill+ for your business or have general questions about SaaS models, our experts can help. To learn more about the benefits of SaaS, contact our experts here.