Proper parts classification and supplier management can save your business millions of dollars. One of the best tools to help manage components and streamline supply chains is Windchill PLM, which offers robust component management features. As a PTC partner, we have seen firsthand how this platform can transform parts management and deliver measurable business value.

The Importance of Parts Management

Parts management is the process of governing part creation and part data to drive faster, more informed decision-making. These decisions impact everything from performance and sustainability to supply chain risk and cost. Engineers are responsible for making choices every day that directly impact your business, however, when they lack clear guidelines or efficient tools, these decisions can lead to inefficiencies and increased costs. Without proper parts classification and management, manufacturers face challenges such as fragmented regional teams. Roadblocks like this prevent manufacturers from reaping the full benefits of parts reuse, leading to unnecessary efforts, higher procurement costs, and disruptions in supply and manufacturing.

The Consequences of Improper Supplier Management

When engineering and supply chain teams aren’t aligned, the consequences are significant. Here are some common issues that arise:

- Poor quality assurance: Without proper part governance, the likelihood of introducing inefficient or duplicate parts increases.

- Supply chain disruptions: Misaligned supplier selections can lead to bottlenecks or delays in production.

- Increased procurement costs: Sourcing from unapproved suppliers or regions can unnecessarily drive costs up.

- Duplication of parts and work: Creating multiple part numbers for the same component wastes resources and complicates inventory management.

These inefficiencies ultimately affect the quality and delivery timelines of products, leading to increased costs and risk across the entire operation.

The Benefits of Parts Management with Windchill PLM

Preventing issues like these is easy with Windchill. Windchill offers powerful features for parts classification and supplier parts management that streamline processes. By leveraging Windchill’s parts management capabilities, companies can achieve the following:

- Increase design reuse: Windchill makes it easy to find existing parts and encourages engineers to reuse components, reducing the need for new part creation.

- Improve productivity: With better part searchability, engineers can focus more on innovation rather than repetitive tasks.

- Reduce search time by over 50%: Windchill’s faceted search capabilities allow users to quickly locate parts based on attributes and classifications.

- Improve quality: With better governance, parts are vetted for quality and compliance, minimizing the risk of subpar components.

- Reduce COGS (Cost of Goods Sold): By reducing the number of duplicate parts and optimizing supplier selection, companies can significantly cut costs.

Part and Supplier Selection

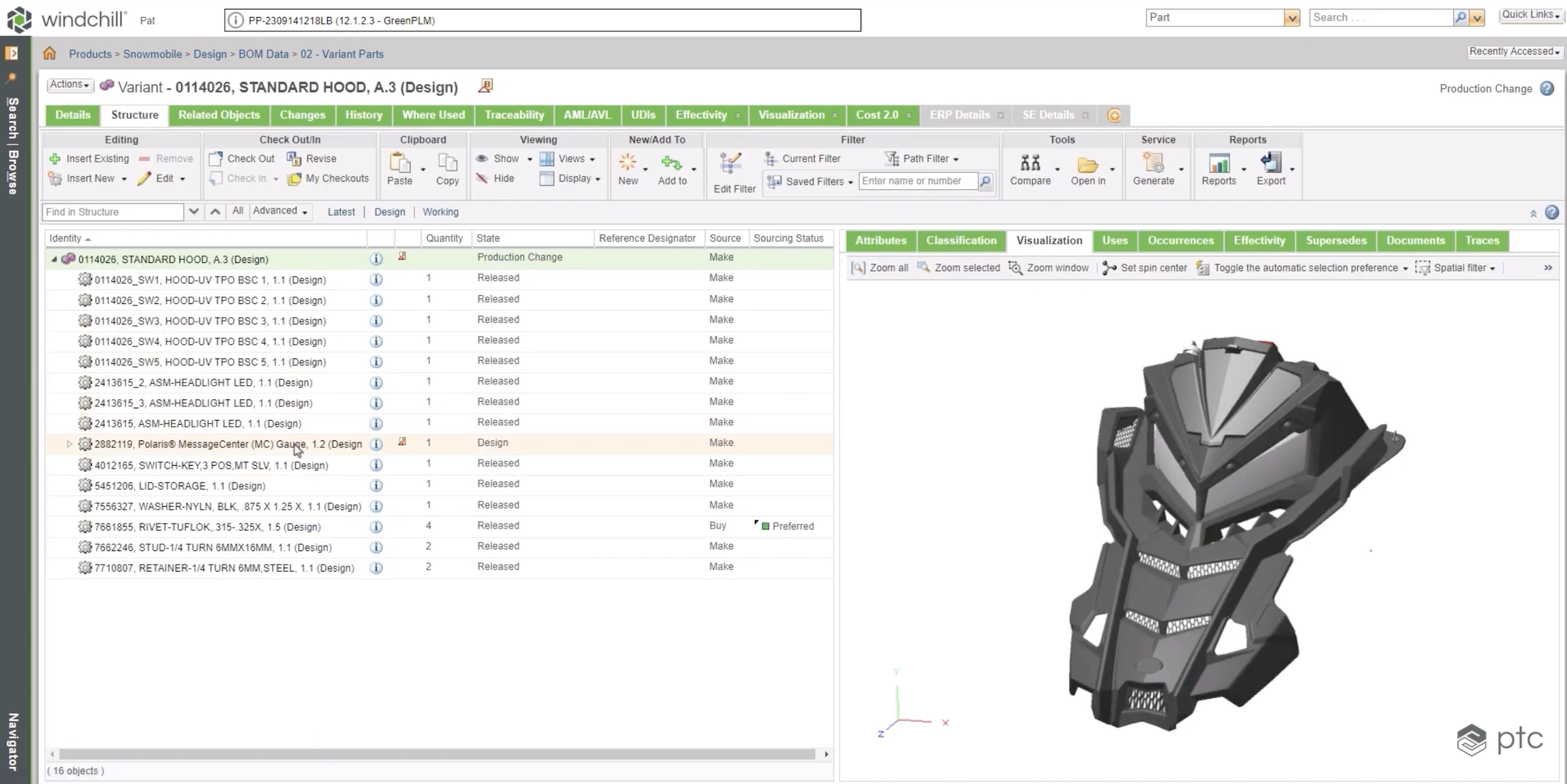

Windchill provides the foundation needed to govern part creation, manage supplier data, and promote parts reuse throughout the organization. Its parts classification structure allows engineers to assign attributes to parts, making them easier to search for and categorize. This not only helps eliminate duplicate part numbers but also makes it easier to find alternative or substitute parts in the event of supply chain disruptions. Additionally, Windchill enables engineers to quickly identify preferred suppliers and manage approved manufacturer lists (AML) and approved vendor lists (AVL) within the same system. This further ensures reduced costs, accelerated time to market, enhanced sustainability, and improved efficiency.

Component Management with Windchill

Windchill’s component management capabilities provide the governance and traceability required to ensure your parts meet regulatory, sustainability, and performance requirements.

Its parts classification and attribute management capabilities allow users to assign and manage part attributes for better searchability and classification. Furthermore, Windchill’s faceted search enables users to quickly find the parts they need. If a supply chain issue arises, Windchill can easily identify backup parts. Lastly, it helps ensure your parts meet sustainability goals and comply with industry regulations.

Utilizing Windchill for Parts and Supplier Management

By eliminating duplication and promoting reuse, Windchill ensures that every part created and used within your organization is fully optimized. At SPK, we help businesses harness the power of Windchill’s parts management capabilities. Whether you are looking to streamline supplier management or eliminate inefficiencies in your parts classification process, we are here to guide you. Contact us today to learn more about how Windchill can help you save time, reduce costs, and improve product quality.