Product development is inherently a complex process, requiring problem-solving and project management skills. Lean manufacturing principles have helped relieve some of this complexity by revolutionizing the way products are designed and created. These principles emphasize efficiency, quality, and customer value, driving innovation across multiple industries. At its core, Lean focuses on continuous improvement and quality management to minimize waste in every aspect of product development. By embracing these principles, organizations can increase product quality, accelerate time-to-market, enhance sustainability, and expand profit margins.

Applying Lean Principles to Product Development

The Lean framework is based on five main principles: identifying value, mapping the value stream, creating flow, establishing a pull system, and seeking continuous improvement. Let’s explore how these principles can be applied throughout the product development process.

Identifying Customer Value

The first lean principle is identifying and understanding what value your business provides to your customers. Not only should you understand your audience, but you should aim to exceed their expectations. For product developers, this means creating a product that addresses real needs while delivering high quality. By maintaining a customer-focused mindset, teams can ensure that products are relevant, reliable, and desired by the market.

Mapping the Value Stream

The value stream refers to all the steps involved in bringing a product from concept to customer. Lean principles encourage teams to identify inefficiencies in this process and eliminate waste. This involves visualizing the workflow, optimizing handoffs, and ensuring that everyone has access to the information they need. With a clear value stream, teams can reduce errors, shorten development cycles, and retain product value at every stage.

Creating Continuous Flow

Continuous flow is about eliminating inefficiencies and ensuring a smooth process from concept to completion. Lean principles encourage collaboration across teams, streamlined workflows, and the elimination of unnecessary bottlenecks. This ensures that adjustments and innovations can be implemented quickly without disrupting overall progress, leading to a more agile and responsive development process.

Establishing a Pull System

Customer pull emphasizes designing products based on customer feedback. In other words, creating a product when there is demand for it. This reduces overproduction and excess inventory. Gathering customer feedback early and often is critical to creating products that align with market needs. This iterative approach helps teams identify issues before production begins, reducing costly revisions and ensuring higher customer satisfaction.

Continuous Improvement

Achieving a “perfect” product consists of continuous refinement and improvement. This is essential to delivering high-quality products and staying competitive. By consistently seeking better ways to design, test, and produce, organizations can enhance their offerings while reducing costs and increasing efficiency. This mindset enables teams to innovate and adapt to changing market conditions effectively.

Why Lean Principles Matter in Product Development

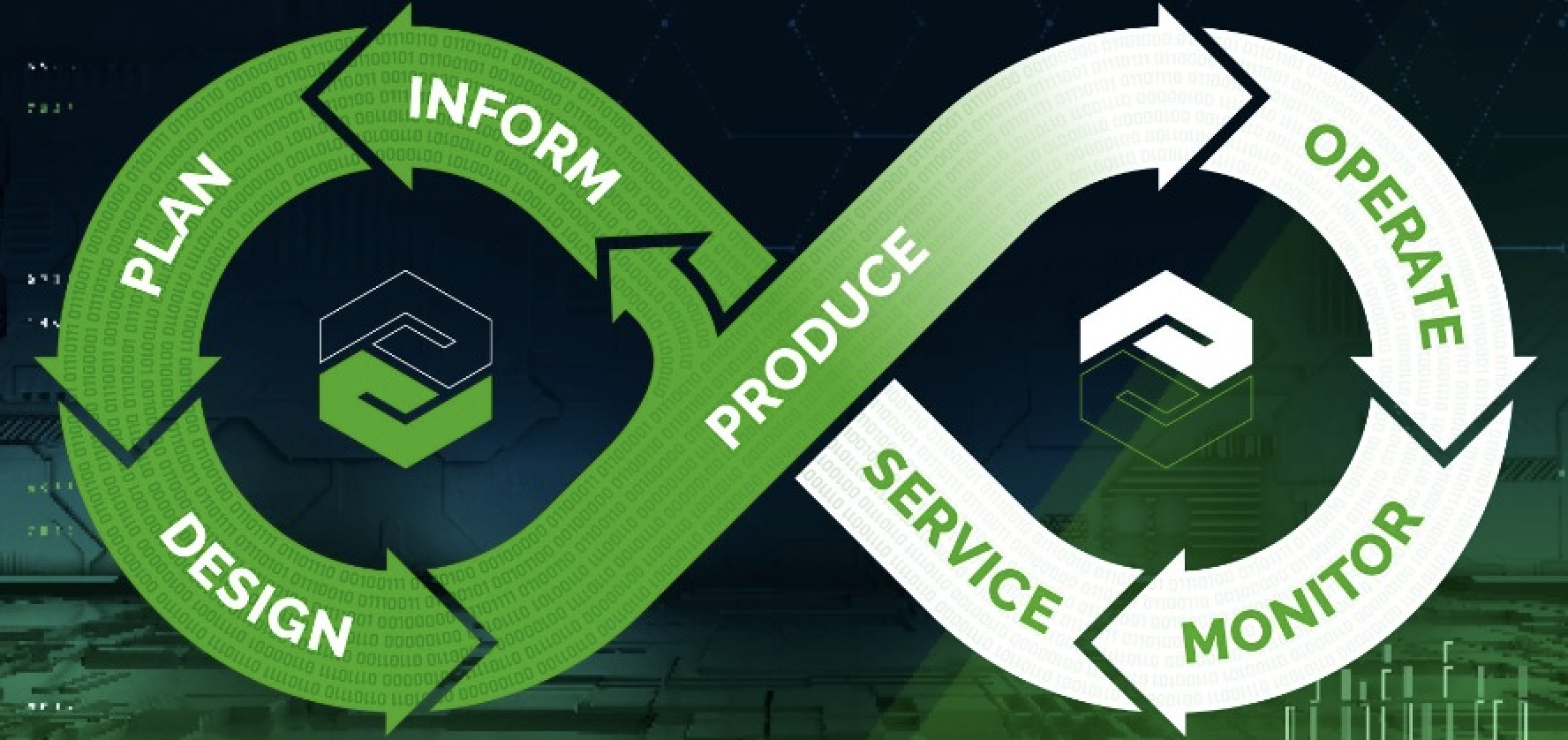

By adopting Lean principles, organizations can optimize their product development processes and improve outcomes. Lean manufacturing is not just about minimizing waste—it’s about maximizing value for both customers and the business. When paired with the correct tools, Lean principles can provide many benefits. The Lean framework works hand-in-hand with the digital thread. Companies like PTC that provide unmatched flexibility, scalability, and collaboration tools align well with Lean principles. Users can use CAD software to design products and PLM and ALM solutions to track changes to components, suppliers, and quality for their products and software. The digital thread integrates these solutions to provide end-to-end visibility from designing to manufacturing.

When the digital thread is combined with the Lean principles, it results in:

- Reduced time-to-market: Streamlining workflows and eliminating inefficiencies ensures faster delivery of new products.

- Enhanced innovation: Encouraging continuous improvement leads to better designs and innovative solutions.

- Increased product quality: Focused attention on value and customer needs results in higher-quality products.

- Enhanced sustainability: Lean practices reduce material and energy waste, supporting environmentally conscious production.

Embrace Lean Principles for Success

Lean manufacturing principles provide a proven framework for simplifying the complexities of product development. Whether your focus is automotive, aerospace, consumer products, or any other industry, applying these principles can help turn ideas into reality. By focusing on value, efficiency, and continuous improvement, organizations can build a culture of innovation and achieve long-term success. If you’re ready to optimize your product development process using Lean principles, reach out to our experts.