Learning from history is vital, yet product management often overlooks the lessons from past mistakes. Product Lifecycle Management (PLM) has evolved significantly since its inception alongside the development of computer-aided design and manufacturing. Today, PLM encompasses a sophisticated process supported by advanced tools like PTC Windchill PLM, essential for successful product development and management.

What Is Product Lifecycle Management?

PLM encompasses managing a product from its initial concept through design, manufacturing, and after-sales service. Additionally, it integrates people, data, processes, and business systems essential for delivering products to customers. Missteps in PLM can be costly, but effective management ensures profitability and customer satisfaction.

Why Is PLM So Important?

Integration Across Departments

PLM provides a unified platform that integrates various departments involved in the product development process, such as design, engineering, manufacturing, and marketing. Essentially, this integration ensures everyone is on the same page, reducing errors and inconsistencies. Plus, it allows for seamless communication and collaboration, leading to more efficient and cohesive product development.

Enhanced Efficiency And Productivity

By managing all aspects of a product’s lifecycle, from inception to retirement, PLM streamlines processes and eliminates redundant tasks. This efficiency translates into faster time-to-market, which is crucial in today’s competitive landscape. Additionally, it helps in optimizing resource allocation and reduces costs.

Improved Quality And Innovation

PLM systems enable better tracking and management of product development stages, leading to higher quality outcomes. They facilitate the collection and analysis of feedback, which can be used to drive innovation. By having a comprehensive view of the product lifecycle, companies can more easily identify areas for improvement and introduce innovative solutions.

Compliance And Risk Management

In many industries, products must comply with various regulatory standards. PLM helps in managing compliance by keeping track of changes and ensuring that all aspects of the product meet the necessary standards. It also plays a crucial role in risk management by identifying potential issues early in the product development cycle, allowing for proactive measures to mitigate risks.

Better Decision Making

With PLM, managers have access to detailed and up-to-date information about every aspect of the product lifecycle. This information is crucial for making informed decisions about product development, marketing strategies, and resource allocation.

Customer Satisfaction And Loyalty

By ensuring that products are of high quality, meet customer needs, and are brought to market swiftly, PLM contributes to higher customer satisfaction. Satisfied customers are more likely to be loyal and provide repeat business, which is essential for long-term success.

Long-term Profitability

Ultimately, the efficiencies and improvements brought about by PLM can lead to increased sales and reduced costs, contributing to long-term profitability. It helps businesses to not only survive but thrive in competitive markets by continuously adapting and improving their product offerings.

The Importance Of Communication And Collaboration

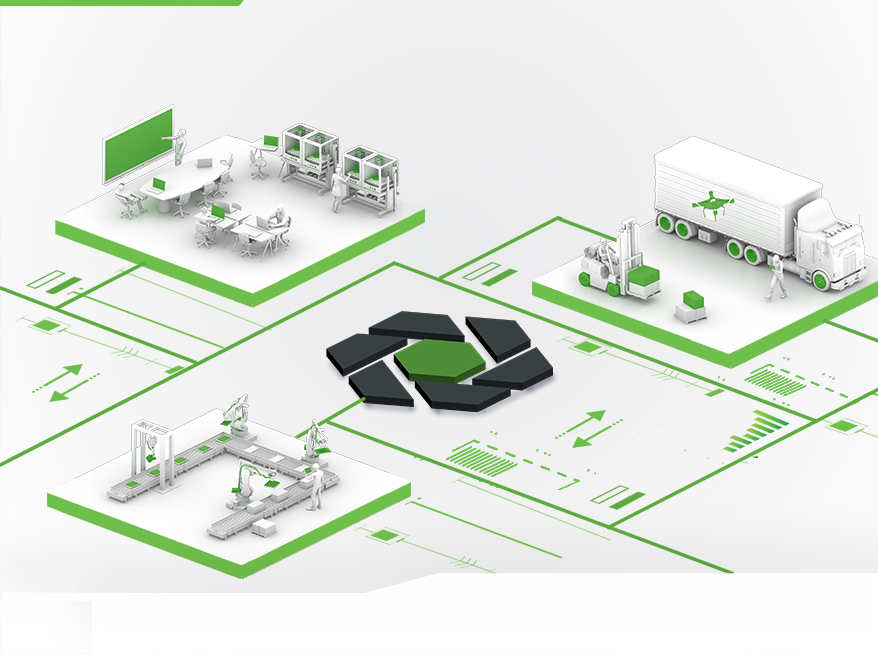

The product lifecycle comprises four critical phases:

Conception, including requirements and planning;

Design and development, involving prototyping and testing;

Manufacturing, which covers supply chain management and delivery;

Servicing, including customer support and maintenance.

Effective PLM requires seamless communication and collaboration across these phases, integrating product data management, change management, ERP, and CRM systems. Fundamentally, this integrated approach is vital for meeting compliance and regulatory standards, foreseeing needs during conception, and managing product data throughout.

Modern Tools For PLM

Managing the extensive data generated in PLM necessitates specialized software. PTC Windchill PLM, a leading solution, offers robust capabilities for data storage and management. For example, it allows engineers to access, modify, and manage product data efficiently, while providing executives with vital reports for cost management and sales strategy formulation. Therefore, implementing such advanced PLM software across an enterprise is crucial. So too is ensuring all users, including engineers and managers, are well-trained and supportive of the system – this is key to successful adoption.

The Role of SPK And Associates In PLM

In the complex world of PLM, choosing the right tools and expertise is crucial. SPK and Associates offer specialized PLM/PDM consulting services, providing expertise in implementing and optimizing PLM systems like PTC Windchill. With a focus on training and supporting teams in effective PLM practices, our team helps organizations avoid common pitfalls and fully leverage their PLM investments.

Conclusion

Effectively managing a product lifecycle from conception to customer support is imperative for producing high-quality, cost-effective products. With the right management, tools like PTC Windchill, and expert guidance from firms like SPK and Associates, organizations can navigate the complexities of PLM, ensuring success without budget overruns or design failures. Contact our team today to learn how we can assist your PLM needs.