Efficient parts classification and supplier integration are critical for streamlining operations and enhancing product development. Utilizing the proper tools can ensure your organization achieves these results. PTC’s Windchill PLM offers a robust solution that allows organizations to classify parts based on specific attributes. It promotes reuse and minimizes inventory, saving your business money. Explore how Windchill can transform your approach to parts classification and supplier management.

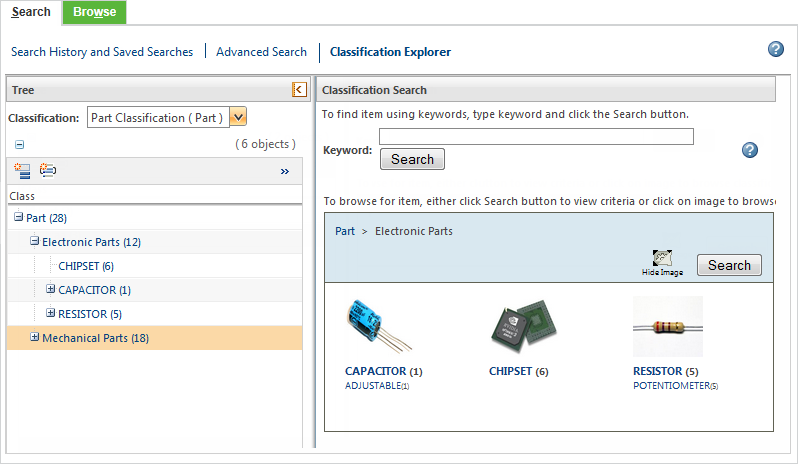

Streamlining Parts Classification in Windchill PLM

At the core of Windchill’s capabilities is the Classification Explorer. This feature allows users to navigate through a hierarchy of classification categories. It enables engineers and designers to efficiently locate parts, even if they lack specific part numbers or names. For example, if you’re searching for a rivet, you can easily navigate to the mechanical components category and explore all classified rivets available in the Windchill system. This classification process enhances visibility and promotes reuse across projects. By categorizing parts based on attributes such as material, diameter, and sourcing information, Windchill empowers teams to spend less time searching for components.

Filtering in Windchill

While users can navigate based on different categories, it can still be difficult to find the right part. Luckily, Windchill enables users to filter components based on unique attributes. Users can efficiently search by for example head type to find the rivet they are looking for. Furthermore, Windchill’s integration with Ansys Granta provides additional material information, such as mass, raw performance data, and sustainability metrics. Searching by material can become even more detailed.

Supplier Integration for Effective Procurement

One of the standout features of Windchill is its supplier visibility including its ability to document supplier information. Windchill ensures that users have access to the correct suppliers based on their location. For instance, if a part is typically sourced from a supplier in Asia, users in North America might need to source the part from a different supplier. This geographic integration is vital for organizations that operate globally, as it guarantees that procurement teams can easily identify their preferred suppliers. Windchill enhances supplier visibility, ensuring that anyone looking to purchase a part can quickly find the appropriate supplier based on their operational region.

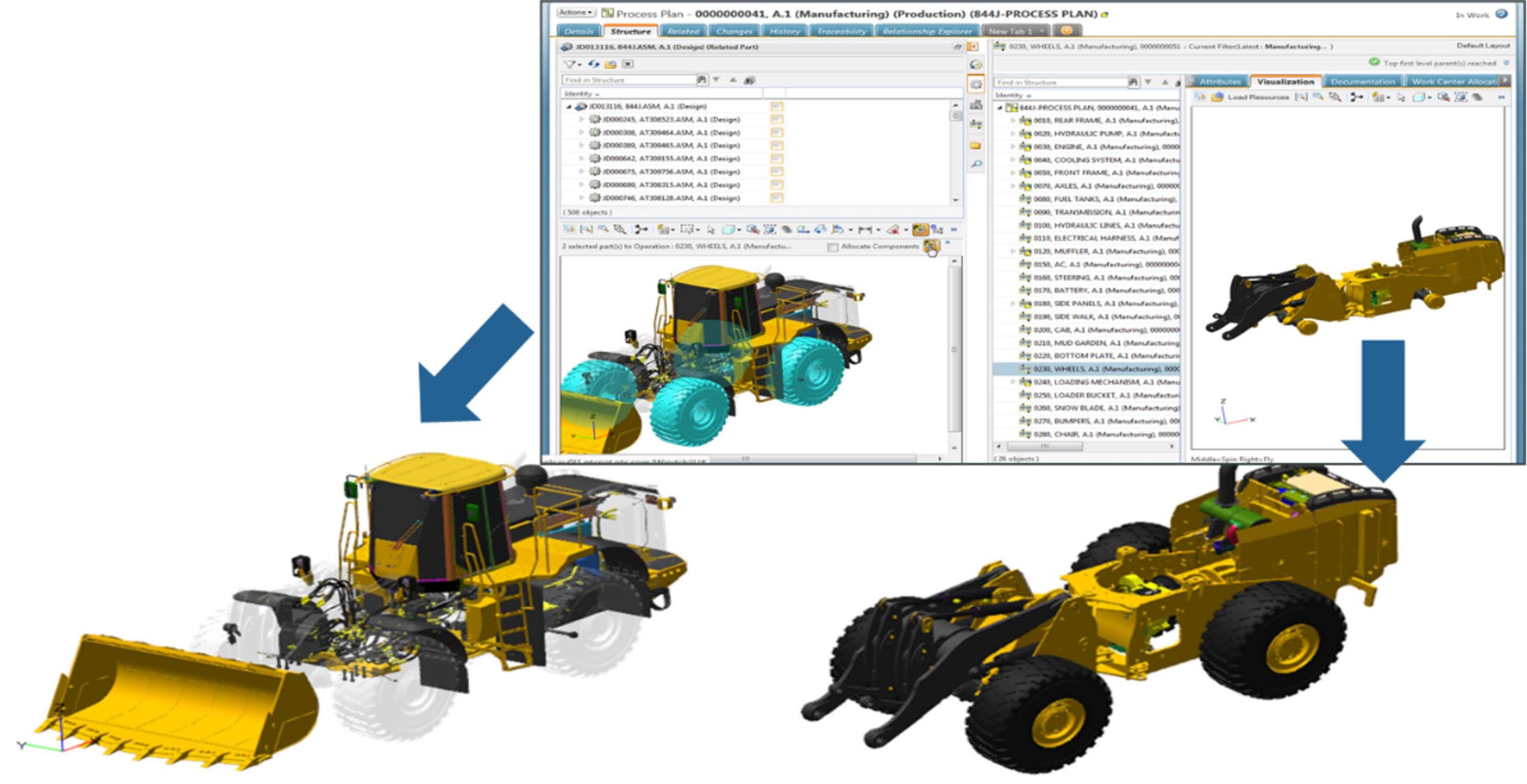

Comprehensive Bill of Materials in Windchill

Windchill does not just offer supplier visibility. It allows users to see how parts are utilized across various assemblies through detailed Bill of Materials (BOM) information. By examining the BOM for a product, users can identify the components required as well as their sourcing statuses. This capability allows teams to make informed choices about component sourcing, especially when it comes to parts that are classified as preferred suppliers.

For example, if a specific capacitor is used multiple times within an assembly, users can quickly assess its manufacturing and vendor information. This includes the identification of multiple suppliers and their preferred statuses. This level of detail ensures that users make decisions that align well with organizational preferences. Additionally, Windchill makes certain that designers have access to critical environmental data in real-time. Understanding the environmental impact of components during the design phase is crucial. 80% of a product’s environmental footprint is determined at this stage, which encourages users to make responsible decisions before manufacturing begins.

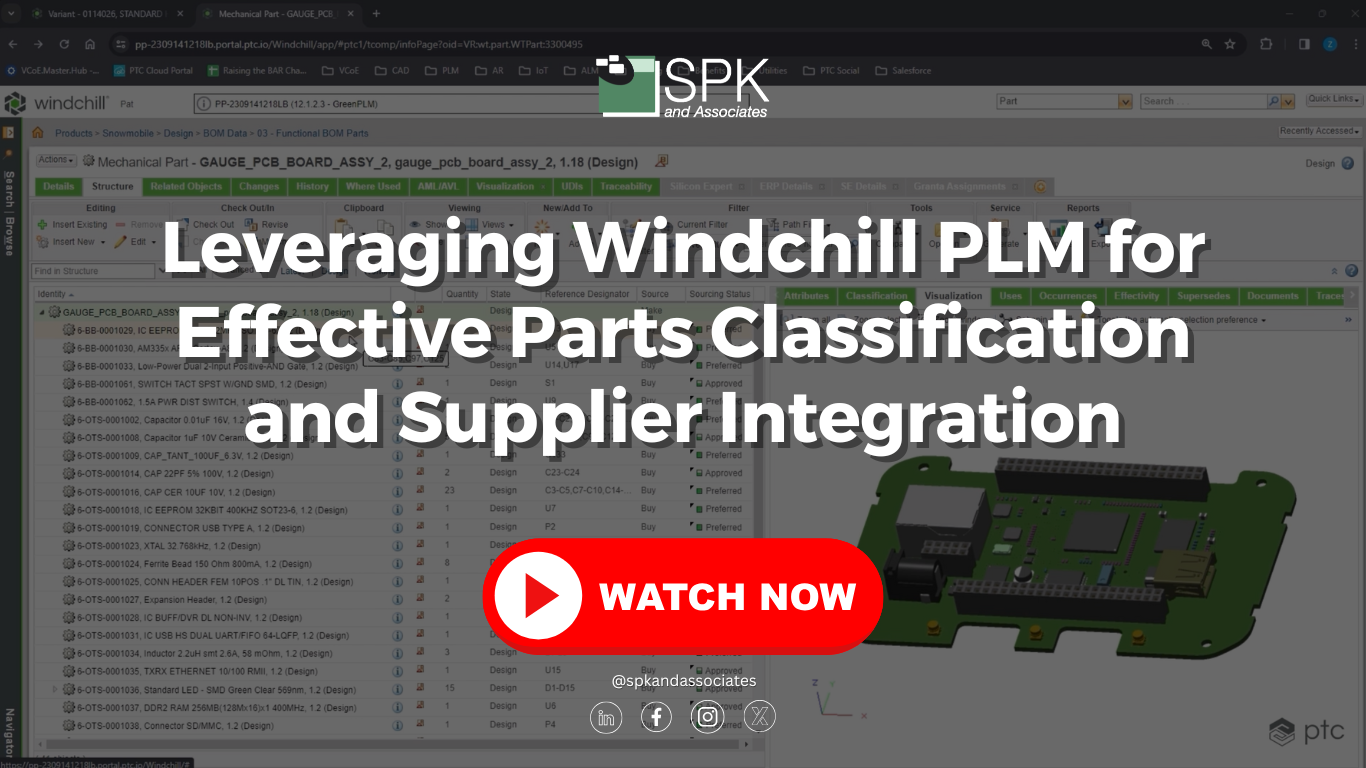

Risk Assessment with SiliconExpert

Windchill also incorporates risk assessment tools into the procurement process to minimize potential disruptions. Windchill integrates with SiliconExpert to evaluate risks associated with lifecycle management, sourcing compliance, and inventory. This integration provides users with insights into the overall health of their BOMs and indicates parts that may carry risks. By leveraging SiliconExpert’s database, users can identify matched parts, review their risk levels, and choose components that align with budget constraints. This proactive approach to risk management fosters a more resilient supply chain. To see all of these features in action, watch the following video:

Implementing Windchill PLM

Windchill PLM provides organizations with powerful tools for effective parts classification and supplier integration. By enhancing visibility into parts, facilitating informed decision-making, and promoting collaboration between procurement and engineering teams, Windchill enables businesses to streamline their operations and reduce costs. Embrace the power of Windchill PLM and unlock the full potential of your parts classification and supplier integration. If you would like to learn more about Windchill or how to get started, contact our experts.