As new tariffs are enacted upon vehicles, auto parts, and raw materials, U.S. automotive manufacturers are facing new challenges. Escalating costs, disrupted supply chains, and uncertain trade policy are among these. While OEMs scramble to mitigate the impact, one strategy is quickly becoming a competitive necessity: automation. This transformation helps manufacturers increase efficiency, improve flexibility, and ensure compliance. As a trusted consulting partner with deep expertise in automotive engineering, SPK helps manufacturers turn disruption into opportunity. Let’s explore how our experts can help you navigate tariffs in automotive manufacturing with digital transformation and automation.

Tariffs and Trade Barriers: A New Era for Automotive Manufacturing

The U.S. auto industry is grappling with the most significant trade shifts in decades. As of April 2025, new tariffs include:

- 25% on Completely Built-Up (CBU) vehicles

- 25% on auto parts (effective May 3, 2025)

- 25% on steel and aluminum imports from China

- Compounding effects leading to $3,000–$10,000+ per vehicle in added costs

These new policies disproportionately affect automakers that rely heavily on global supply chains. European and Asian OEMs such as BMW, Volvo, and Mazda are expected to feel more stress, while U.S.-based brands like Ford and Tesla fare slightly better due to localized production. However, even domestic manufacturers will be impacted. Most vehicles built in the U.S. use thousands of imported parts. The Ford F-Series, for example, sources components from over 24 countries. Tariffs now apply to any portion of a vehicle not compliant with the United States-Mexico-Canada Agreement (USMCA). This means price increases. To maintain competitiveness, automakers must rethink production strategies, shift sourcing, and embrace automation to mitigate costs and boost agility.

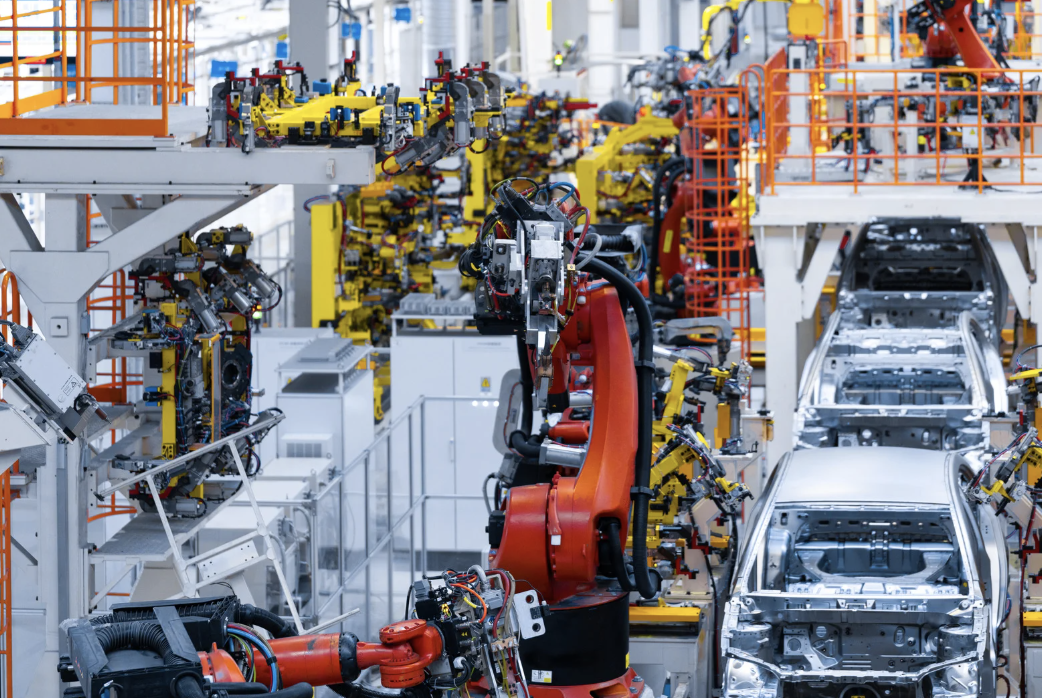

Advancing Automation in the Automotive Industry

At SPK, we recognize automation as a necessity for organizational efficiency. However, it is also a strategic response to tariffs. Our team helps clients evaluate and implement automation throughout the product lifecycle, from design to production.

We’ve guided automotive clients through CAD/CAM automation using Creo. This helps streamline detailed design, generative modeling, and additive manufacturing. In addition to this, we have utilized digital twins to simulate production lines. This helps identify optimization opportunities before physical investment. Furthermore, we have helped clients automate repetitive engineering tasks such as BOM generation and tooling reuse via Windchill PLM. All of these implementations increase efficiency, saving organizations time and money.

Proven Outcomes

A great example of PTC tools in action is this case study on STRATTEC Security Corporation. STRATTEC, an engineering firm that develops and manufactures automotive parts, implemented PTC Windchill. This improved design tracking and collaboration for its engineers. By integrating with existing CAD tools and supporting industry compliance standards, Windchill enabled STRATTEC to streamline operations, reduce design costs, and increase productivity. Windchill’s capabilities combined with automation gave engineers time back and reduced scrap and rework.

In SPK’s experience, our clients have achieved increased throughput and production line efficiency from our automation services. Additionally, we help reduce reliance on tariff-exposed parts through supply chain optimization. Furthermore, we have experience helping clients achieve shortened development cycles and fewer late-stage errors.

Strengthening Supply Chain Management Through Automation

Global supply chain complexity has always been a challenge, but today’s tariffs make it urgent. SPK modernizes supply chain operations by deploying Windchill PLM to create a dynamic digital backbone. Windchill’s automated supplier collaboration and real-time tracking makes organizing parts, materials, and stakeholders, simple. Not to mention its digital thread-driven re-sourcing strategies help optimize supply chain operations. This gives manufacturers the agility to respond to tariff policy changes, shift suppliers, and trace compliance documentation with minimal manual intervention.

In addition to this, SPK can also integrate Windchill with ERP systems to synchronize part sourcing, cost modeling, and production planning. This helps manufacturers reduce risks and make data-driven decisions in real time. Overall, our services provide better visibility into the supply chain, allowing the proper shifts to be made.

Automating Testing and Compliance to Future-Proof Operations

While everything may be changing in the supply chain, compliance with automotive industry standards like ISO 26262 and IATF 16949 must stay consistent. SPK can help with this. We can enable automation of quality assurance processes using digital QMS systems. These QMS systems are easily integrated directly into the manufacturing workflow.

Our experts specialize in setting up automated test environments for vehicle components. We can also digitize PPAP and APQP documentation using Windchill. Additionally, we help map real-time data to compliance checklists and audit trails. The result? Reliable regulatory compliance, even during rapid design or sourcing changes. All of this is done while avoiding costly rework and production delays.

Combining Technology, Expertise, and Industry Best Practices

SPK brings together cutting-edge technologies like PTC Windchill and Creo with hands-on experience. Our team understands automotive design principles, engineering processes, manufacturing automation, and how to remain in compliance with regulatory standards. In addition to PLM and CAD, we also have experience implementing DevOps platforms from software companies such as GitLab. Through industry insights from sources such as Automate Show and PTC, we stay ahead of trends and help clients align their automation strategy with the future of mobility. The main value we provide can be explained through our acronym, ACEs.

SPK’s ACEs

- Accelerated Time to Market: Speed production adaptations and vehicle launches

- Ensured Compliance: Automate QA and regulatory processes across the product lifecycle

- Cost Efficiency: Minimize manual effort and optimize sourcing strategies

- Exceptional Quality: Deliver consistent, high-quality automotive products at scale

Prepare for the Future with SPK’s Automotive Manufacturing Expertise

Tariffs are being implemented for better or worse, and the long-term need for resilience is clear. Automation, digital transformation, and compliance are no longer optional. They are core to surviving and thriving in this new era of U.S. automotive manufacturing.

SPK and Associates is the partner that can guide your business through it. We help automotive OEMs and suppliers modernize operations, reduce tariff impact, and capture new opportunities with confidence.

Ready to automate and accelerate? Contact SPK to discover how we can help your operations turn disruption into a strategic advantage.