In regulated industries, engineering and quality teams must move fast enough to support innovation, but carefully enough to meet strict compliance requirements. This can be a difficult balancing act, and when critical product data lives in disconnected systems, that balance becomes harder to maintain. At SPK and Associates, our experts built MasterManager to help teams alleviate this exact issue. MasterManager connects SolidWorks PDM and MasterControl, so teams can work from a single, trusted source of truth. Let’s dive deeper into how MasterManager helps organizations streamline engineering release processes.

The Hidden Risk of Data Silos

Most engineering organizations rely on multiple systems to manage different parts of the product lifecycle:

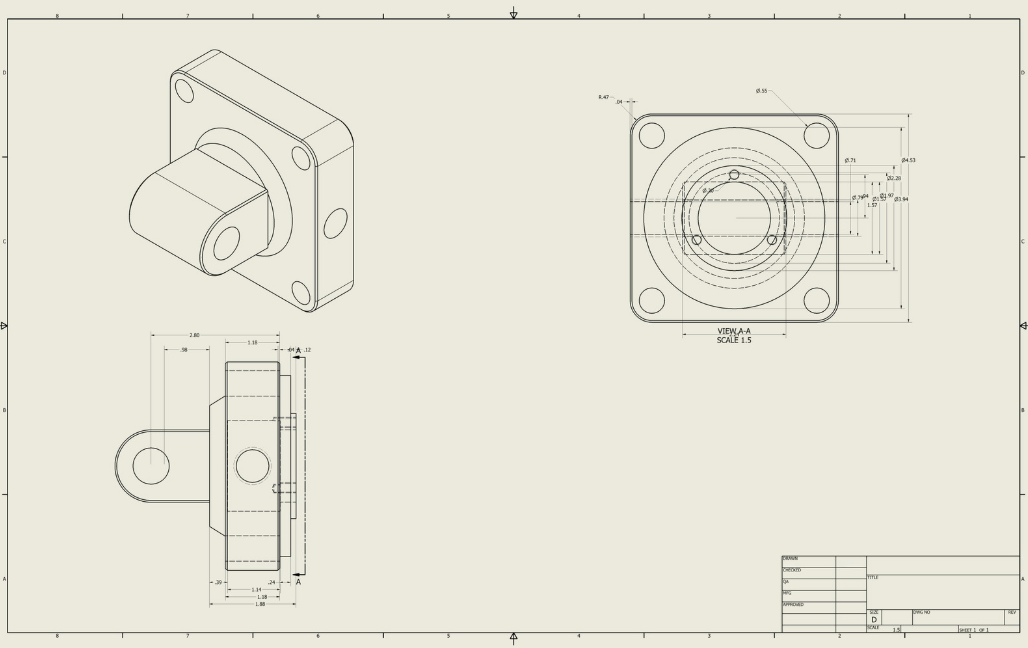

- PDM systems to manage CAD files and technical documentation

- QMS platforms to manage controlled documents and compliance records

This separation is unavoidable. Different tools serve different purposes. However, when these systems are not connected, problems emerge. Without automation, teams are forced to manually upload drawings and PDFs into the QMS and constantly re-enter metadata such as part numbers and revisions. Additionally, they must cross-check documents across systems and maintain parallel approval workflows. Over time, this creates data silos. Information becomes fragmented, duplicated, and difficult to verify.

In medical device and life sciences environments, even a small mismatch between systems can lead to:

- Incorrect documentation being released

- Delayed approvals

- Additional validation work

- Increased audit risk

- Lost engineering time

Manual processes also introduce human error, and in regulated manufacturing, a single incorrect drawing or revision can have serious downstream consequences.

Why Integrating SolidWorks PDM and MasterControl Matters

Many manufacturers use SolidWorks PDM as their system of record for engineering data. At the same time, MasterControl serves as the authoritative system for quality documentation.

Both platforms are powerful on their own, but without integration, teams are left managing two separate versions of reality.

An automated PDM-to-QMS workflow helps organizations:

Establish a Single Source of Truth

Approved engineering documents in PDM automatically appear in MasterControl, ensuring consistency across systems.

Reduce Manual Handling

Engineers no longer need to upload, rename, and classify files manually.

Improve Traceability

Revisions, approvals, and change histories stay aligned between engineering and quality systems.

Accelerate Release Cycles

When documentation flows automatically, reviews and approvals move faster.

Support Compliance

Auditors can clearly see that controlled documents originate from validated engineering sources.

Instead of managing two disconnected repositories, teams operate within a unified digital thread.

How MasterManager Makes It Possible

MasterManager is SPK’s cloud-based integration platform that bridges SolidWorks PDM and MasterControl. It acts as an intelligent connector that monitors workflows, applies business rules, and transfers the right data at the right time.

Key Capabilities

Automated File Transfer

When a drawing or document reaches an approved state in PDM, MasterManager automatically exports PDFs, STEP files, and other formats to MasterControl.

Metadata Synchronization

Part numbers, descriptions, revisions, and other attributes are mapped and transferred automatically.

Workflow-Based Triggers

Data movement is driven by PDM lifecycle states, such as “Released” or “Approved.”

Configurable Rules

Organizations can define exactly which files and fields are synchronized and when.

Error Prevention

Validation checks ensure that incomplete or incorrect data does not enter the QMS.

Secure, Cloud-Based Architecture

The connector operates reliably across environments while supporting compliance requirements.

Behind the scenes, MasterManager compares records, reconciles changes, and ensures that engineering and quality systems stay aligned without constant human intervention.

Connecting Engineering and Quality Case Study

If you would like to see MasterManager in action, check out this case study. To summarize, a leading medical device manufacturer was facing challenges managing its documentation across SolidWorks PDM and MasterControl. Engineers had to manually upload approved documents into MasterControl, leading to inconsistencies, errors, and slower release cycles. At one point, an incorrect drawing was even sent to manufacturing due to misalignment between systems. To resolve these issues, SPK implemented MasterManager as a secure, configurable connector between the two platforms. This led to more reliable document control, faster releases, stronger collaboration across teams, and improved compliance audits.

Turning Disconnected Systems into a Digital Thread

Disconnected PDM and QMS systems create unnecessary risk. Manual uploads and duplicate data entry are not just inefficient; they undermine confidence in documentation and slow down innovation. MasterManager changes this dynamic by eliminating manual steps, improving traceability, and freeing engineers to focus on innovation.

At SPK and Associates, we design integrations that fit each client’s environment, workflows, and regulatory needs. MasterManager is not a one-size-fits-all tool. It is a configurable platform built on deep engineering and compliance expertise. If your teams are still managing PDM and QMS systems separately, it may be time to connect them and move from fragmented processes to an integrated digital thread. Let’s talk about how MasterManager can support your engineering and quality operations.