Designing and manufacturing aerospace products demands precision, innovation, and an unwavering commitment to safety. Engineers must balance complex assemblies and stringent regulatory standards while using lightweight materials. PTC Creo provides a comprehensive suite of tools that empower engineers to easily navigate these challenges. From concept design to manufacturing, Creo enhances efficiency, ensures compliance, and drives innovation in aerospace product development.

Designing Quality Aerospace Equipment

In aerospace design, quality and safety are the top priorities. If a product doesn’t start with a solid concept, it risks failure. This leads to revenue loss, wasted resources, and worst of all, unsafe consumers. Additionally, aerospace components require strength, durability, and lightweight materials to achieve optimal performance. PTC Creo empowers manufacturers to innovate and explore multiple design options while ensuring quality and operational safety. It offers advanced tools to support concept design, such as:

- Freestyle Design – Rapidly create high-quality freeform and stylized geometry.

- Parametric Surfacing – Define free-form surfaces with constraints and parameters.

- Design Exploration – Quickly iterate and evaluate design alternatives.

- Render Studio – Create photorealistic images for concept visualization and marketing.

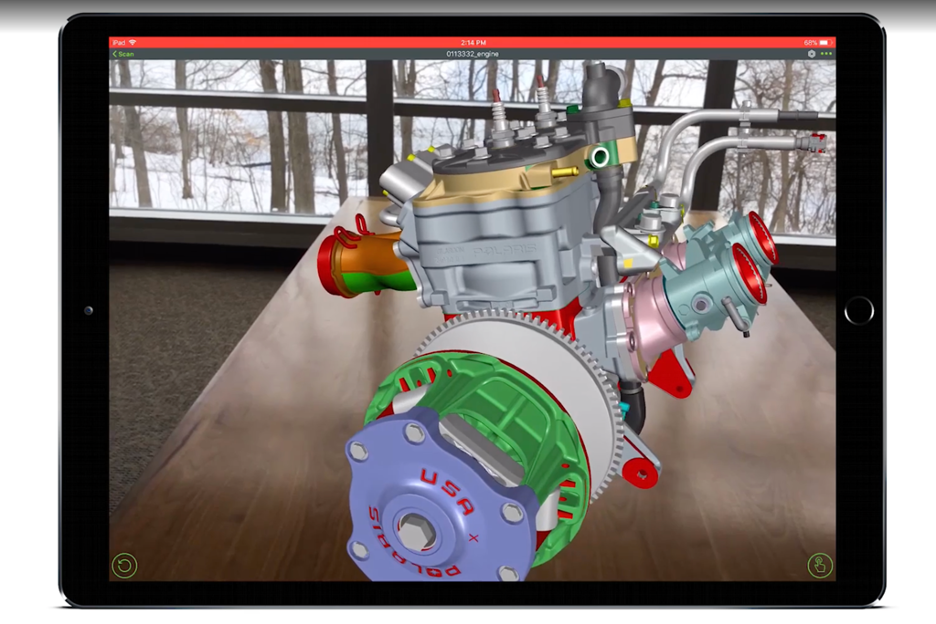

- Augmented Reality (AR) Design Share – Enhance design collaboration through AR-based reviews.

These capabilities ensure that designs are structurally sound and aligned with safety requirements from the start. Engineers can easily create and share concepts before moving to detailed design.

Ensuring Safety and Performance in the Details

Once a concept is finalized, engineers must refine and document every detail to meet strict aerospace standards. Aircraft components are not designed for aesthetics but for performance, and durability. Even the smallest component impacts the overall system, requiring meticulous attention to detail.

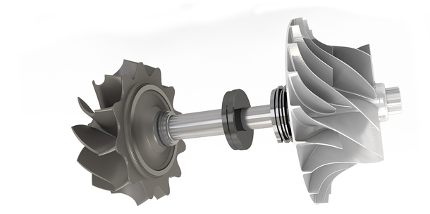

Creo offers many capabilities that allow engineers to refine their original designs. Its advanced assembly feature allows engineers to manage large-scale designs with top-down design principles. Additionally, its mechanism design and piping and cable design features offer ways to model and analyze kinematic motion. These features also optimize the routing of 3D cable and piping systems. Creo’s EZ tolerance analysis allows engineers to analyze tolerance stack-up to ensure precision. Meanwhile, its GD&T advisor ensures all geometric dimensioning and tolerancing are in compliance with industry standards. By leveraging Creo’s design capabilities, engineers can ensure every part meets performance and safety requirements before moving into production.

Testing Aerospace Equipment to Ensure Structural Integrity

Aerospace components operate under extreme conditions. Any exposure to high loads, forces, and vibrations can shorten product lifecycles and lead to catastrophic failures. That is why simulation is essential. Testing, validating, and optimizing designs early in the process prevents issues post-production.

Creo provides a complete suite of simulation tools to support aerospace engineers, including:

- Creo Simulation Live – Complete real-time simulation for immediate design feedback from other engineers.

- Creo Ansys Simulation – Test designs under intense conditions, offering high-fidelity structural, thermal, and modal analysis.

- Mechanism Dynamics – Analyze the dynamic performance of moving parts to ensure everything runs smoothly before manufacturing.

- Fatigue Advisor – Predict and optimize each component’s lifespan under stress.

- Flow Analysis (CFD) – Evaluate internal and external fluid dynamics under different pressure levels.

By integrating simulation-driven design, manufacturers can identify and resolve potential flaws before production. This reduces reliance on costly prototypes and helps mitigate risks.

Quality from Concept to Manufacturing in Aerospace Engineering

Aerospace manufacturers often handle both design and production in-house to maintain control over material properties, machining precision, and assembly integration. This ensures everything runs smoothly and is assembled properly for peak safety precautions.

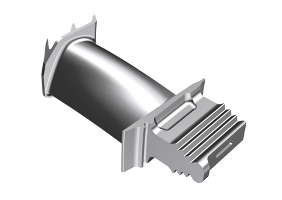

Creo offers integral manufacturing solutions to streamline production. Firstly, it offers high-speed milling. This feature offers support for 3- and 5-axis machining for precision manufacturing. Creo also offers additive manufacturing or 3D printing capabilities for rapid prototyping and metal part production. Additionally, Creo users can automate mold, die, and progressive die design for efficient manufacturing. Furthermore, engineers can use multi-axis turning and wire EDM processes to create complex shapes. Finally, Creo enables harness manufacturing which automates cabling documentation for aerospace electrical systems. By maintaining CAD data associativity and automating manufacturing processes, Creo helps aerospace manufacturers reduce costs, improve quality, and accelerate time-to-market.

Ready to Navigate the Complexities of Aerospace Engineering with Creo?

PTC Creo provides the necessary tools to navigate the complexities of aerospace design, from concept to manufacturing. By integrating innovative design tools, real-time simulation, and advanced manufacturing solutions, Creo enables aerospace companies to produce high-quality, high-performance products. All while minimizing risk and reducing costs. Whether developing next-generation aircraft or refining existing designs, Creo ensures aerospace manufacturers meet the industry’s rigorous demands with confidence. If you are interested in learning more about Creo for aerospace design or other engineering disciplines, contact our experts today.