The automotive industry is very competitive, leaving manufacturers scrambling to innovate, meet regulatory demands, and quickly deliver higher-quality products. In this fast-paced environment, investing in digital transformation is essential. The best way to ensure seamless product deployment is to implement a digital thread. By leveraging PTC’s comprehensive PLM, ALM, and CAD solutions, automotive manufacturers can create an interconnected system that drives efficiency, collaboration, and continuous innovation. Let’s dive deeper into the impact of the digital thread in automotive manufacturing.

The Power of the Digital Thread in Automotive Manufacturing

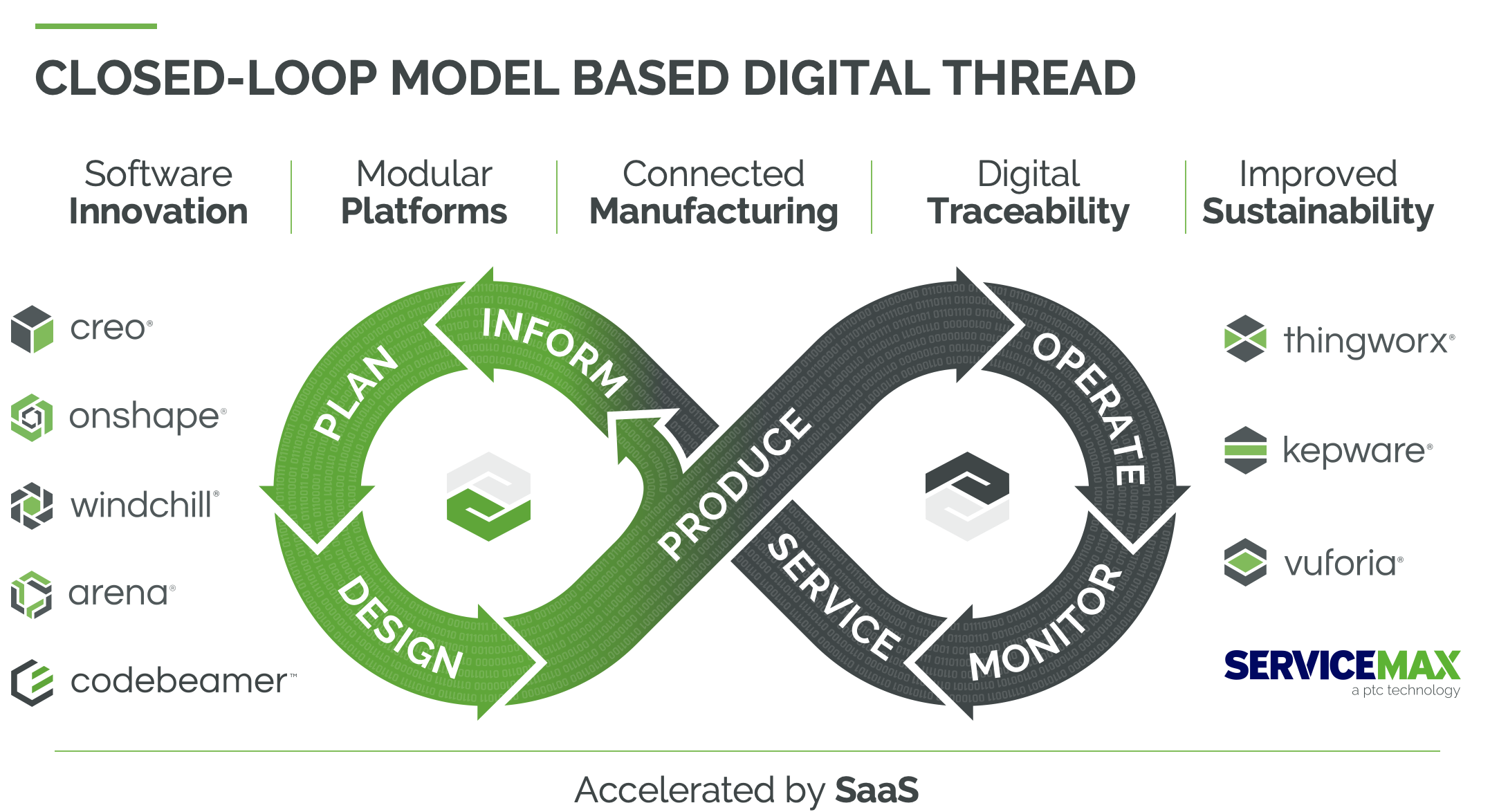

The Digital Thread is a framework that integrates data and information across the entire automotive product lifecycle. From design to after-sales service, the digital thread keeps everything interconnected. In the automotive industry, complexity is always increasing due to new technologies such as electric vehicles. The digital thread allows manufacturers to streamline and standardize processes across the supply chain, lessening this complexity.

One of the main benefits of the digital thread is ensuring current product data is always accessible to anyone who needs it. This can improve collaboration across departments, lead to faster decision-making, and enhance traceability. Additionally, the digital thread helps manufacturers ensure compliance with regulatory standards, and reduce their time-to-market.

Implementing a Digital Thread in Automotive Manufacturing with PTC

Windchill PLM

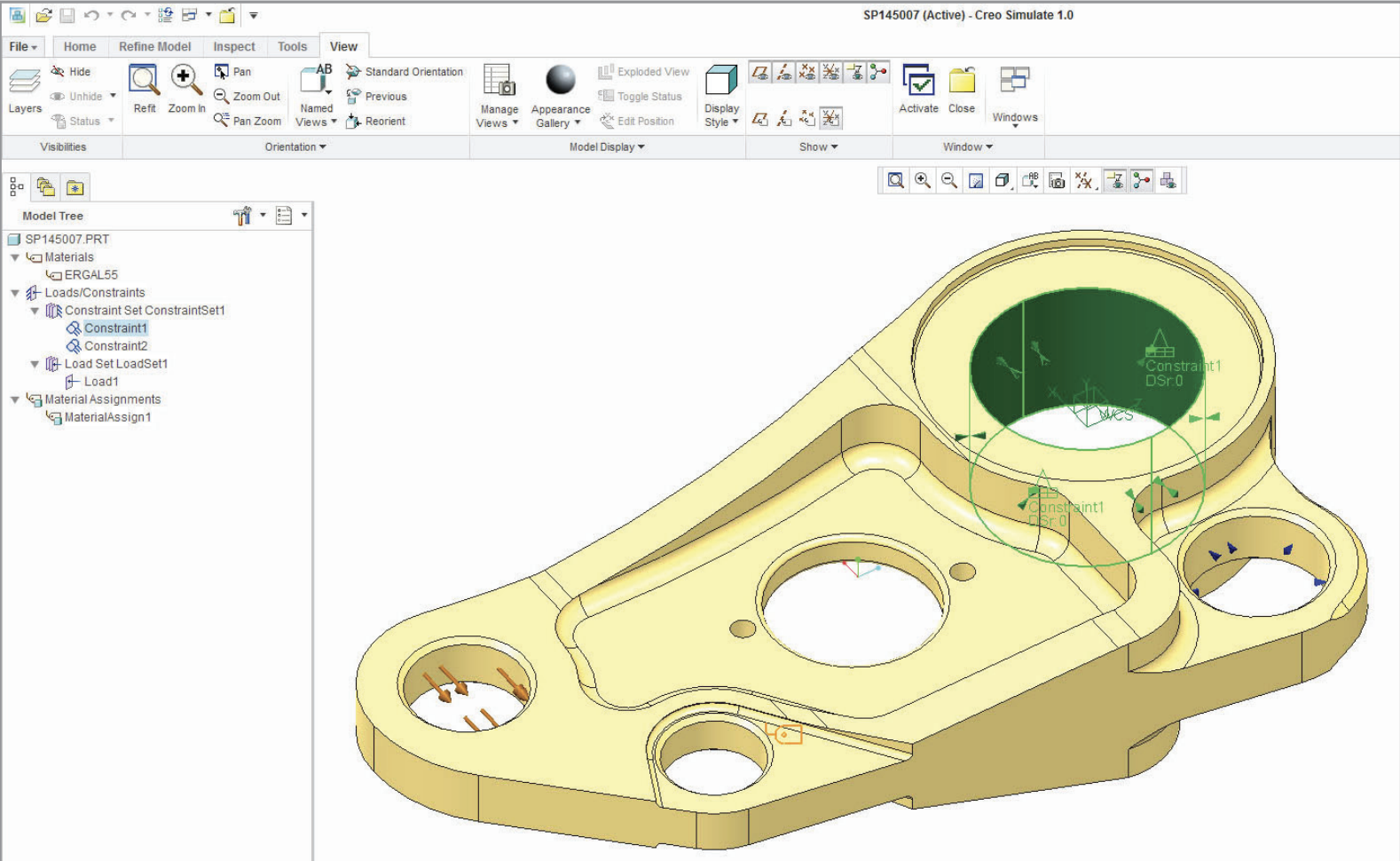

When implementing a digital thread, it is important to utilize the proper tools. PTC offers a wide range of solutions that seamlessly integrate to make your manufacturing process easy. Windchill PLM is the backbone of the digital thread, allowing automotive manufacturers to manage product data. Windchill’s integration with MultiCAD systems allows design, engineering, and manufacturing teams to collaborate in real-time. This eliminates miscommunication and errors, reducing development time from traditional cycles of 72 months to as little as 36 months.

Additionally, the digital thread automates many manual processes, which helps improve speed and accuracy. If automotive manufacturers need anything changed within the product design, this can easily be communicated and implemented due to the digital thread. Windchill’s product and manufacturing information management capabilities ensure companies reduce errors due to incorrect measures. Windchill helps improve overall product quality and increases time to market.

Software-Defined Vehicles and MBSE

As the automotive industry shifts toward Software-defined vehicles, complexity increases. PTC’s model-based systems engineering (MBSE) toolchain helps automotive companies manage this complexity by enabling early validation and verification through simulation. By using a model-based approach, companies can ensure all aspects of the system are tested before implementation. It also allows teams to reuse existing models to cut down on development time.

Electric Vehicle Development with the Digital Thread

Software-defined vehicles are not the only new technology in the automotive industry. Electric vehicles are also on the rise, as is the demand for product innovation. The digital thread, powered by PTC products, enables more efficient EV development by optimizing processes and helping meet compliance requirements. Moreover, AR-enabled tools help service technicians access real-time product data which can be used to improve safety during high-voltage maintenance. This not only results in higher safety standards but better customer satisfaction due to faster service times. This is just another example of how the digital thread improves every aspect of the product lifecycle from development to maintenance.

Optimizing Manufacturing With ThingWorx DPM

In addition to its PLM and ALM tools, PTC’s ThingWorx DPM platform drives continuous improvement across manufacturing processes. With real-time insights and data-driven metrics, automotive manufacturers can optimize assembly times, improve product quality, and lower energy costs. Furthermore, ThingWorx PDM allows organizations to reduce hours of manufacturing and assembly time per vehicle as well as identify and resolve issues within the production line.

Ready to Implement the Digital Thread?

To stay competitive within the automotive industry, manufacturers need to focus on innovation, efficiency, and collaboration. By implementing a digital thread powered by PTC Windchill PLM, automotive manufacturers can stay ahead of the curve. To learn more about how you can drive success with a digital thread, contact our experts today.