Achieving differentiation through superior design is essential in the electronics industry where products often function similarly and cost comparably. Making your product stand out against the competition can help your business achieve success. PTC’s Creo enables companies to blend mechanical and electronic design seamlessly, offering a suite of advanced tools that drive innovation, quality, and efficiency. From concept to manufacturing, Creo allows engineers to meet the rigorous demands of the electronics market. It ensures products are functional, visually appealing, and user-friendly. Let’s dive deeper into how Creo transforms the design process for electronics.

Turning Ideas into Electronics with Creo

In the electronics industry, first impressions matter. Products that are visually appealing and intuitive to use stand out in a crowded market. They help build brand loyalty and capture consumer interest. Balancing form with function can be difficult as the product should be both aesthetically and ergonomically pleasing. Exploring different design concepts can also be time-consuming.

Design Capabilities

Creo offers freestyle and interactive surface design capabilities that allow users to create complex, freeform, and stylized geometry. These design tools can be used to enhance aesthetics and usability. In addition to this, Creo allows users to rapidly iterate and evaluate design concepts using checkpoints and direct edits. This helps ensure every concept is optimized for consumer appeal and functionality. Furthermore, Creo allows users to share their AR experiences and gather feedback during the design process. Lastly, Creo’s render studio generates photorealistic images to help stakeholders visualize the end product during the review process. With Creo’s tools, companies can innovate quickly, ensuring their concepts stand out while reducing the risk of failed launches and wasted resources.

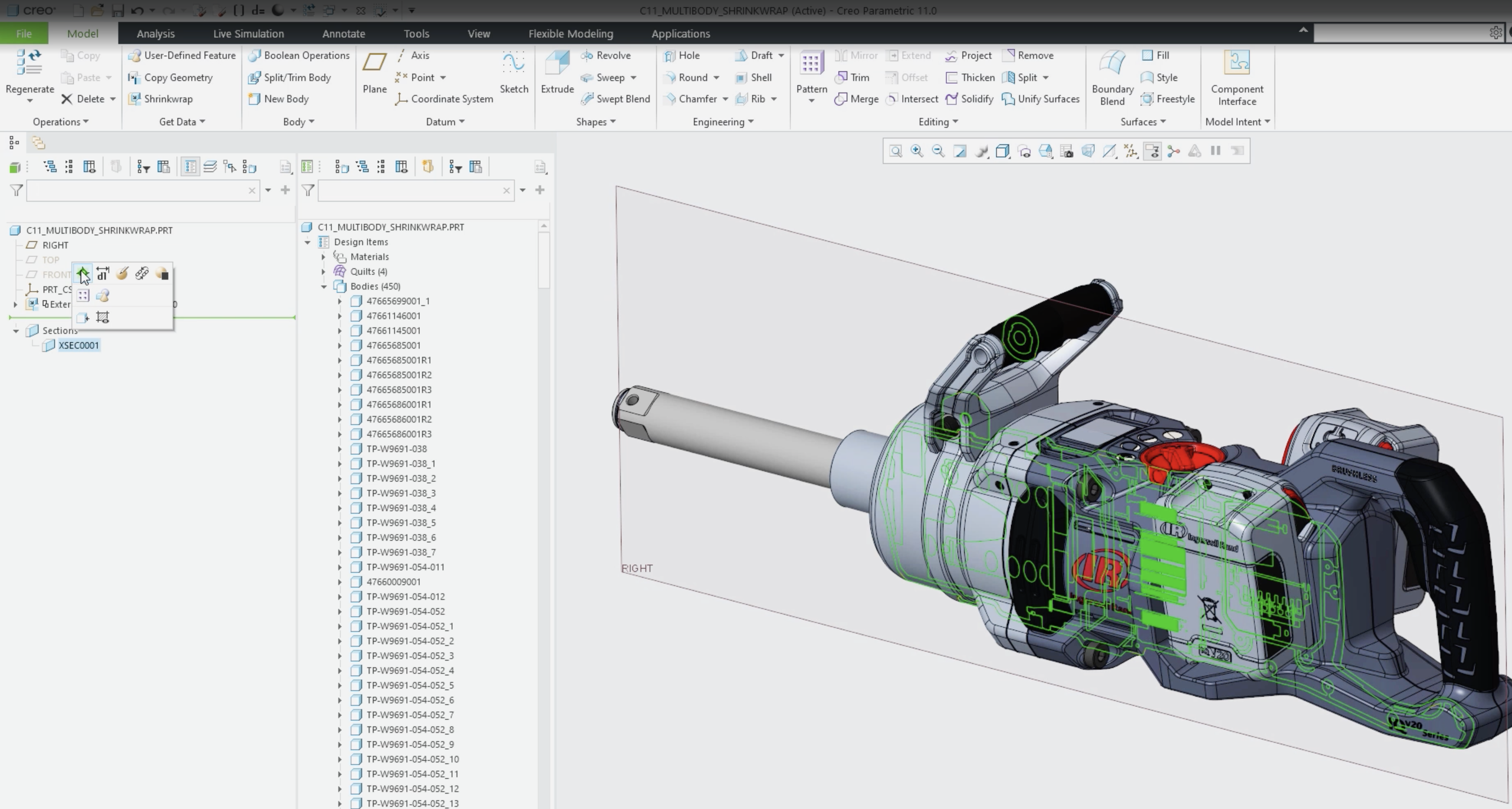

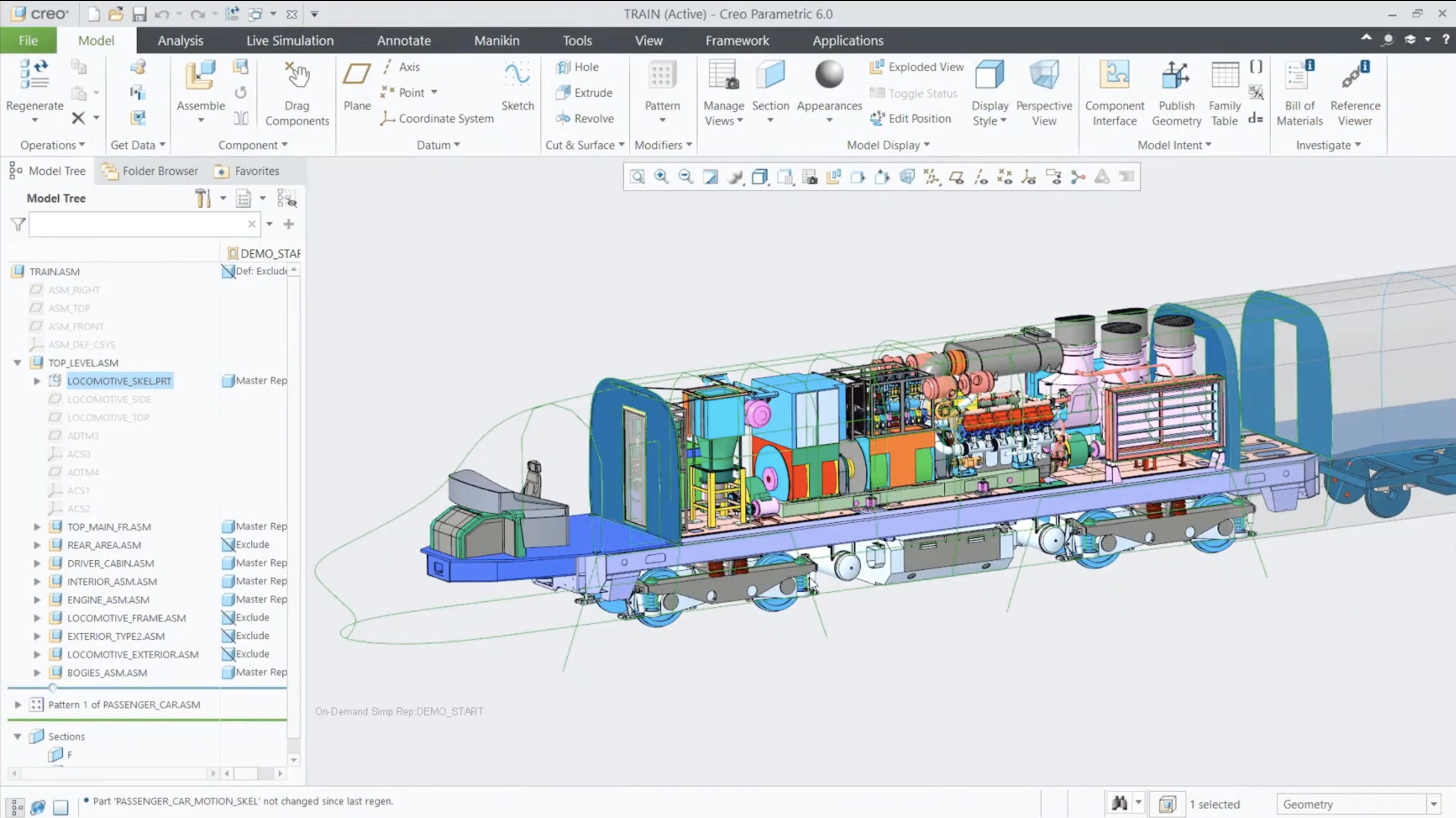

Enhancing Electronics with Creo

Once a concept is finalized, engineers must refine their design as well as integrate mechanical and electronic components. This includes ensuring precise fit, usability, and manufacturability while maintaining high quality. The detailed design stage often has challenges related to component incompatibility and miscommunication. To resolve this, users may use Creo’s advanced assembly modeling to ensure all components fit perfectly. By using concurrent engineering and top-down design, managing large assemblies becomes simple. Creo also allows for cable and piping route optimization which helps seamlessly integrate electronic components. Its advanced capabilities bridge the gap between mechanical and electronic design, ensuring a flawless final product.

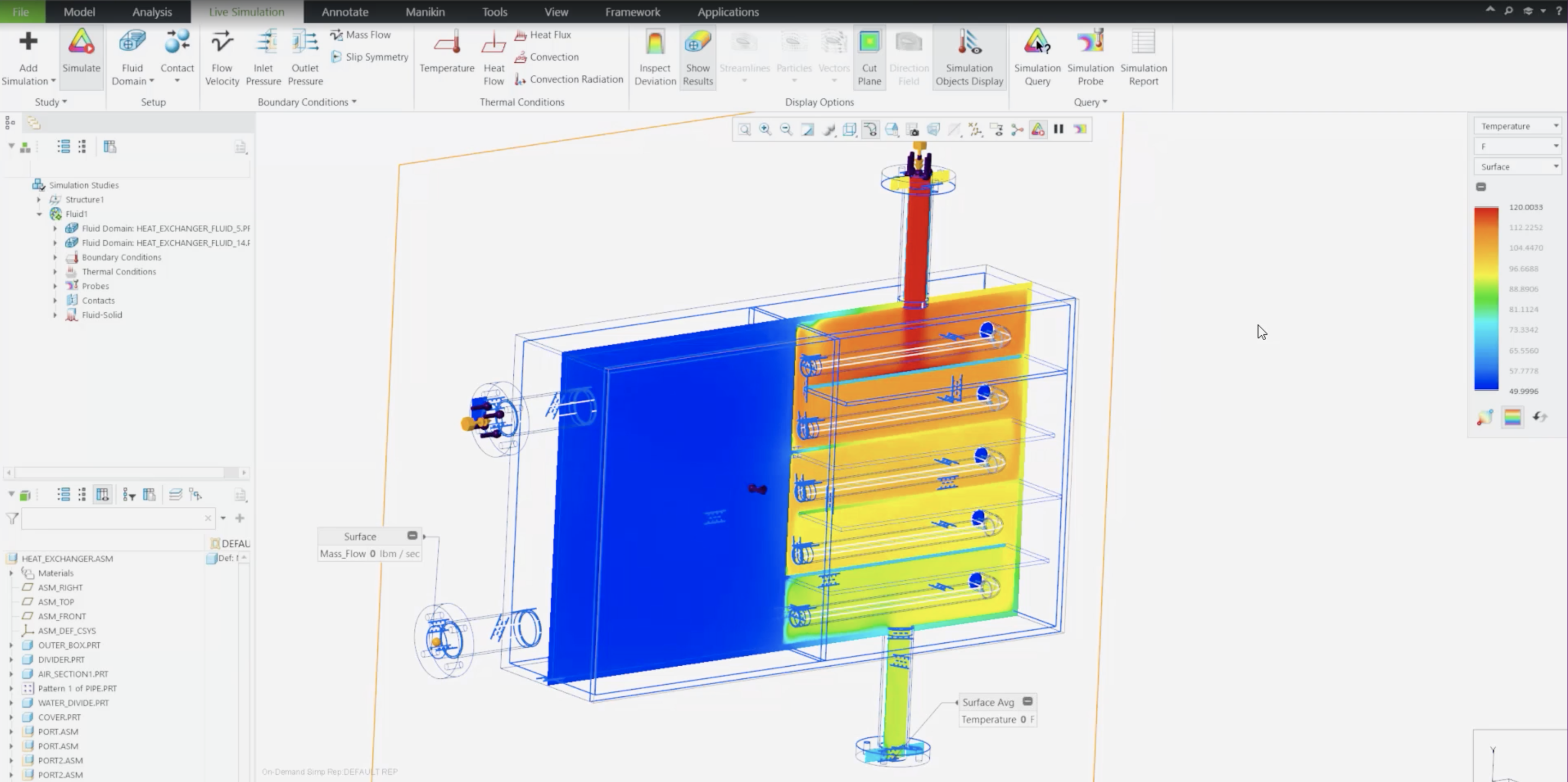

Ensuring Quality and Performance with Simulation

The complexity of electronic products demands robust simulation to eliminate design flaws, optimize performance, and enhance durability. Simulation-driven design is critical to mitigating risks and ensuring reliability. Costly late-stage revisions are a direct result of improperly testing your product, making this stage vital. While meeting lifecycle and durability requirements can sometimes be difficult, Creo’s simulation capabilities help guide decisions to exceed them. Simulation Live allows users to use real-time analysis to evaluate and optimize designs. Furthermore, its advanced simulation tools allow engineers to test designs in different environments, testing thermal, structural, and vibration dynamics. Not only does this stage optimize design integrity and performance, but it also eliminates electrical design flaws before manufacturing.

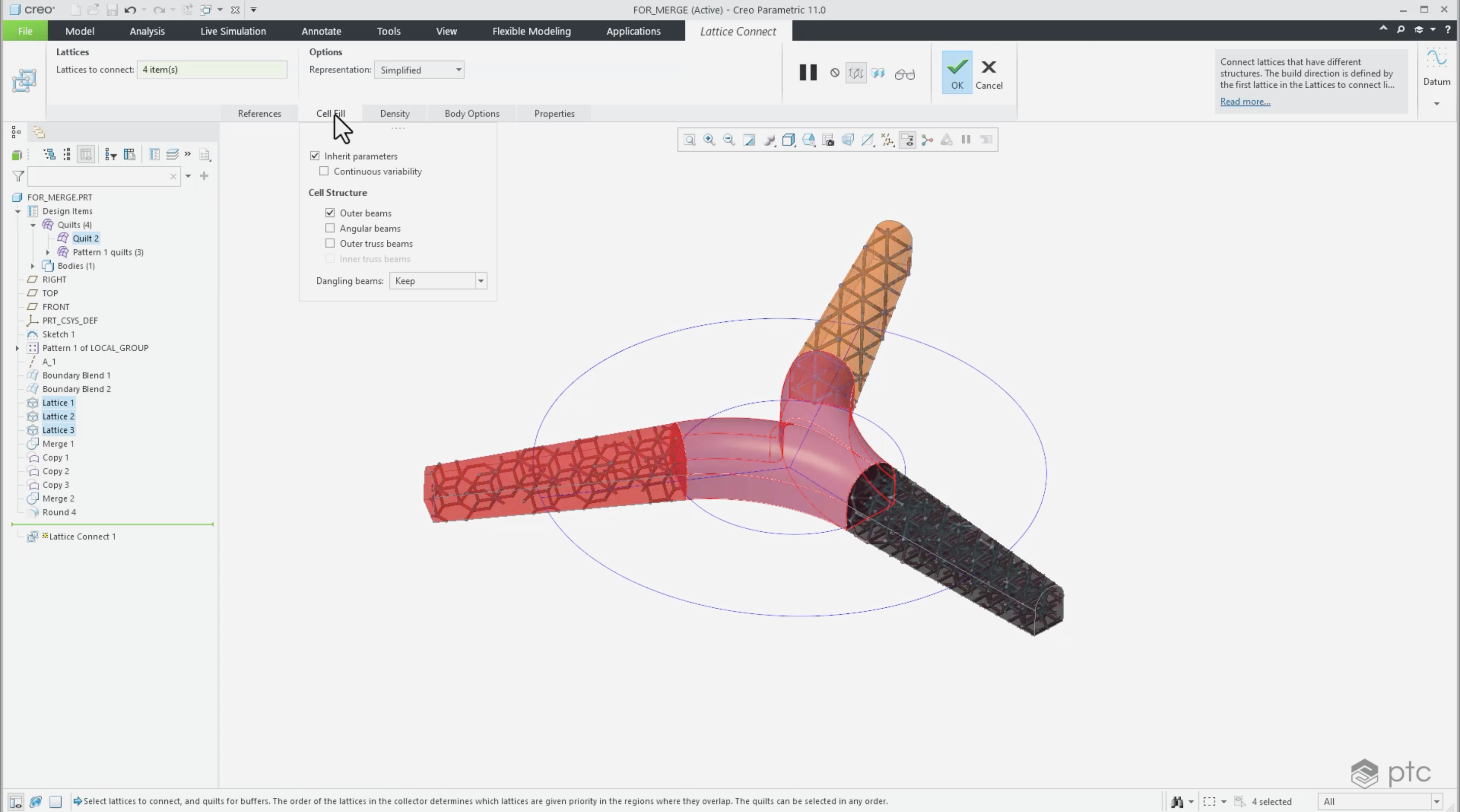

Manufacturing Electronics with Creo

Ensuring a seamless transition from design to manufacturing is essential to reduce time-to-market, lower costs, and maintain quality. Creo helps engineers meet the precise requirements of electronics production. Its NC machining and tooling design capabilities allow the automation of mold, die, and progressive die designs for rapid production. Furthermore, it supports advanced 3- and 5-axis machining which are extremely precise in their creation of intricate electronic components. Lastly, its additive manufacturing capabilities allow users to integrate 3D printer connectivity and lattice structure for more efficient production. Overall, Creo helps companies meet tight deadlines, reduce costs, and deliver high-quality products from concept to production.

Why Choose Creo for Electronics Design?

Creo is a game-changer for electronics companies aiming to differentiate their products in a competitive market. Its comprehensive tools support every stage of the design process. Creo’s capabilities allow engineers to optimize designs with precision, create stunning, innovative products that captivate consumers, and seamlessly integrate mechanical and electrical components.

Ready to Up Your Electronics Manufacturing Capabilities?

Creo empowers companies to thrive in the electronics industry by turning complex design challenges into opportunities for innovation. If you are ready to revolutionize your designs, let Creo be your partner in creating the next generation of electronics. To learn more about how Creo’s advanced tools can elevate your electronics design process, contact us. Give your business a competitive edge today.