In the high-stakes world of motorsports, speed is not just a requirement for the track, but a necessity throughout the design and manufacturing process. The demand for innovation, quality, and consumer appeal at a quick pace has led design teams to encounter unique challenges. To combat these challenges, design teams must implement the proper tools to help them meet customer expectations. PTC’s Creo emerges as a powerful CAD solution, encouraging innovative design. Let’s explore how Creo empowers motorsport manufacturers to excel from concept design to manufacturing.

Capturing Consumer Appeal

There is no debate that in the motorsport industry, good-looking products sell better. Consumers gravitate toward equipment that doesn’t just deliver exceptional performance, but is aesthetically pleasing. Brands must differentiate themselves through design that captures the attention of the consumer. This is why the concept design stage is so critical for brand success. A weak concept can lead to dissatisfied customers, wasted resources, and diminished revenue.

How Creo Supports Concept Design:

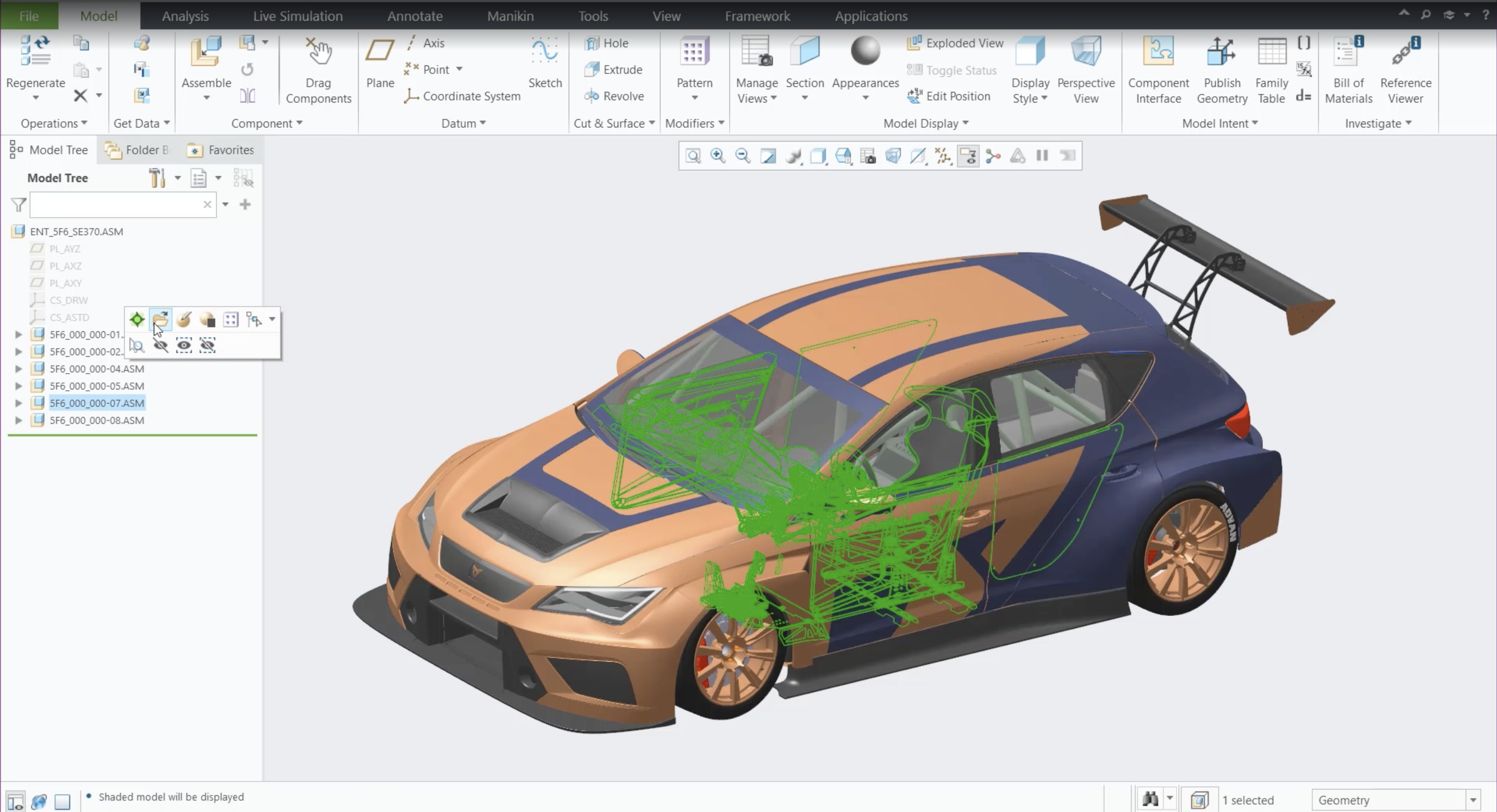

Creo supports the conception stage by allowing designers to quickly evaluate multiple concepts. They can generate and test different ideas, ensuring they move forward with the best one. Additionally, Creo offers tools and extensions like Freestyle Design and Interactive Surface Design, which allow designers to craft sleek, freeform shapes and stylized geometry. These make the designs more aerodynamic as well as visually appealing. Furthermore, Creo offers AR capabilities such as AR Design Share which enables the secure sharing of augmented reality experiences. This lets designers easily showcase how their designs will perform to stakeholders. In addition to AR, Creo also allows designers to create photorealistic renderings to use for marketing and sales efforts. Lastly, Creo’s additive manufacturing integration capabilities allow for quick and easy iteration cycles when refining different prototypes.

Designing High-Performing Products

After a concept is finalized, the detailed design phase ensures every component of the motorsport equipment meets all standards for accuracy, quality, and functionality. Engineers work on integrating mechanical and electrical systems and optimizing assembly fit, ensuring designs are ready for manufacturing.

How Creo Drives Detailed Design:

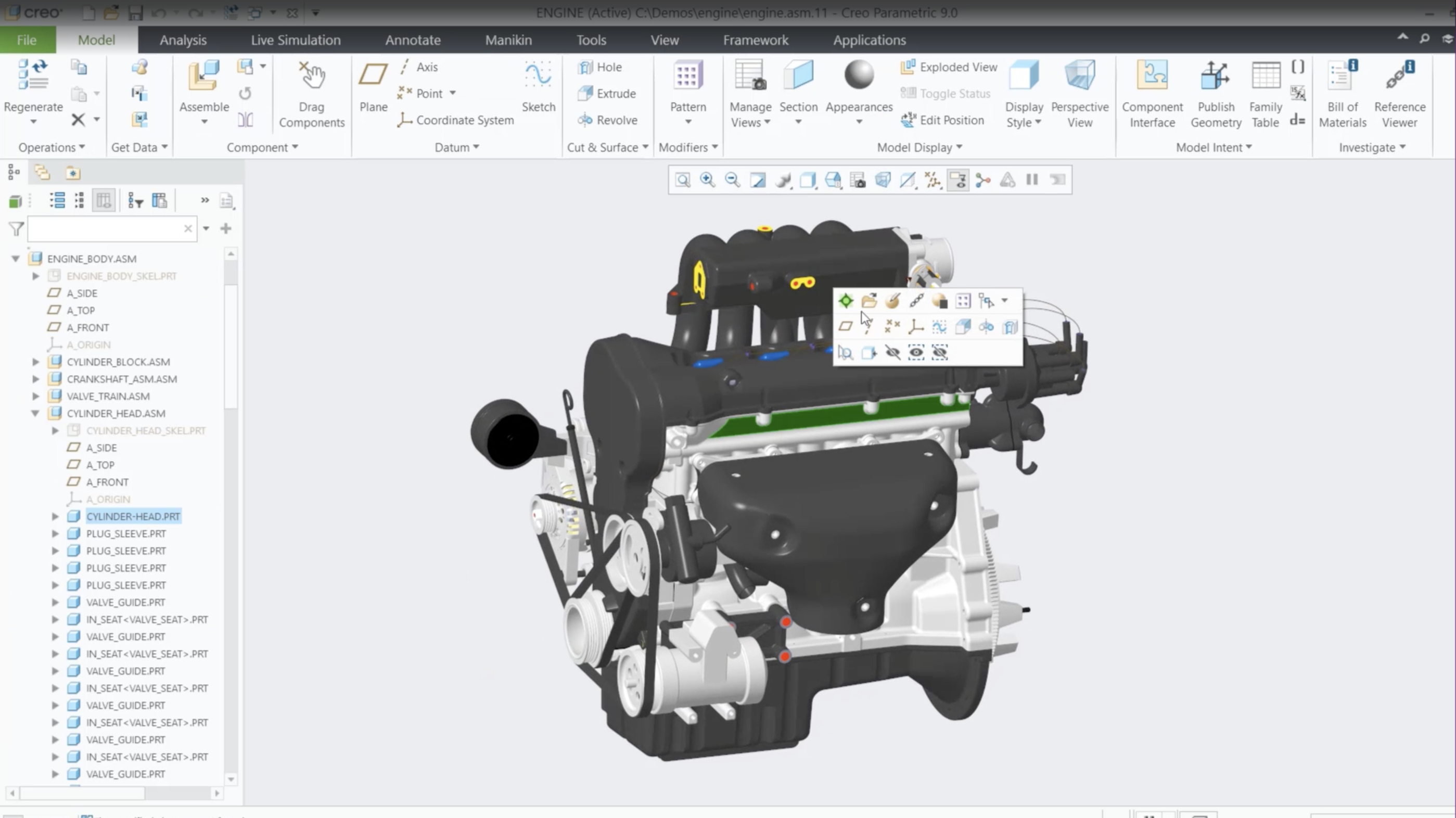

Creo’s Advanced Assembly tools facilitate the design of large, complex assemblies. It does so by enabling top-down design and concurrent engineering practices. Additionally, it allows designers to optimize designs using Behavioral Modeling and Generative Design. Furthermore, Creo prioritizes usability and safety, helping manufacturers design equipment that meets performance and user-centric requirements. Lastly, tools like its GD&T Advisor and Schematics streamline the creation of detailed, accurate documentation. These documents ensure all relevant information is provided for the manufacturing and assembly processes.

Ensuring Quality and Durability

Motorsport products must endure extreme conditions without compromising on performance or safety. Engineers rely on simulation to validate designs, optimize structural integrity, and refine motion dynamics.

How Creo Enhances Simulation:

Creo offers a feature called Creo Simulation Live which provides immediate feedback on designs. This feature acts as a virtual design coach to evaluate and refine designs during development. Tools like Creo Ansys Simulation and Flow Analysis allow engineers to perform in-depth studies on how designs perform in certain environments. Examples include testing structural integrity, thermal behavior, and fluid dynamics. In addition to this, Creo’s Fatigue Advisor can predict the lifecycle of components under stress. This test helps reduce the risk of product failure in the future. Lastly, Mechanism Design and Dynamics tools within Creo allow teams to analyze motion, ensuring that assemblies perform as intended under operational conditions. Simulation-driven design eliminates the need for costly prototypes and late-stage changes, enabling manufacturers to launch products with confidence.

Manufacturing: From Design to Production

The motorsport industry thrives on precision manufacturing. Every piece must be crafted with accuracy and efficiency. Fortunately, Creo seamlessly integrates design and manufacturing, ensuring consistency.

How Creo Supports Manufacturing:

As mentioned previously, Creo’s Additive Manufacturing capabilities streamline the creation of complex assemblies. Not only does this help quickly produce prototypes, but it helps quickly bring designs to production. Other tools like Prismatic, Multi-Surface, and High-Speed Milling support advanced machining techniques that reduce time-to-market. Creo’s automated tools for moldbase and progressive die design simplify the creation of manufacturing tooling, improving production speed and cost-efficiency. Lastly, Creo seamlessly maintains CAD data integrity across processes which eliminates errors and ensures smoother transitions from design to production.

Creo for Motorsport Equipment Design

When it comes to designing motorsport vehicles, Creo delivers the powerful features needed. Beyond Creo’s core capabilities, users can enhance their workflows with advanced features like additive manufacturing, generative design, and augmented reality (AR). Furthermore, Creo helps companies create visually appealing, functional, and enjoyable motorsport equipment by focusing on brand differentiation, style, and usability.

Ready to Utilize Creo for Motorsport Equipment Design?

The motorsport industry demands speed, precision, and innovation and Creo delivers. Whether it’s crafting eye-catching designs or accelerating production, Creo equips manufacturers with the tools needed to meet the fast-paced demands of motorsport. If you are interested in driving innovation in your motorsport designs, contact our experts today. We will show you how Creo can help your team bring optimal products to market.