Organizations are increasingly turning to Model-Based Definition (MBD) to revolutionize their engineering and manufacturing processes. By embedding rich, digital annotations directly into 3D models, MBD provides a single source of truth for product definitions. This leads to significant cost savings and operational efficiencies. In fact, recent studies reveal that organizations leveraging MBD have achieved a 41% reduction in engineering change orders (ECOs) and a 47% decrease in scrap. Here’s how transitioning to a Model-Based Enterprise (MBE) drives this impressive return on investment (ROI).

The Evolving Role of Engineering Documentation

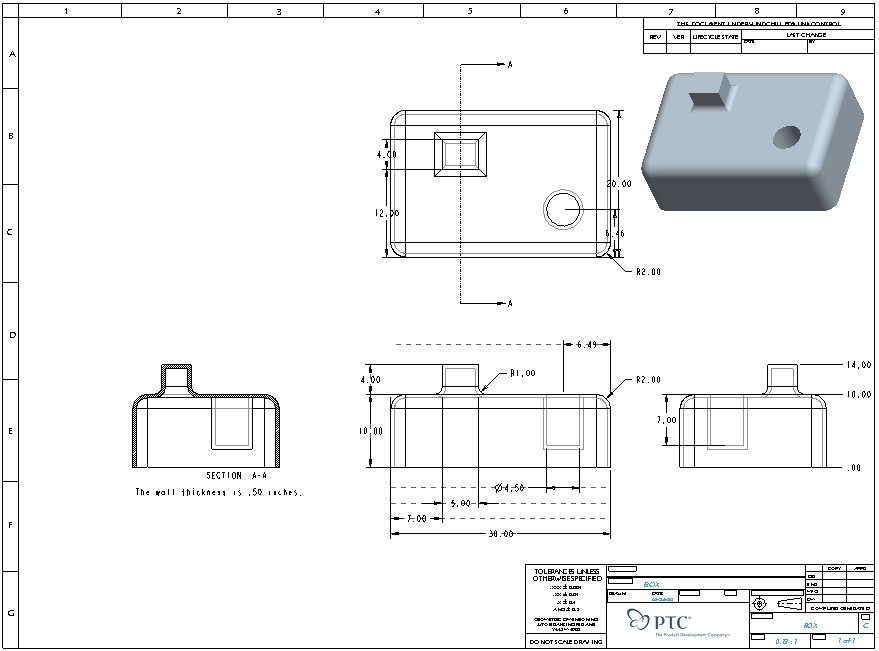

Before exploring the importance of MBD, let’s uncover the necessity of engineering documentation. Engineering documentation serves two primary purposes:

- Convey the complete and detailed geometric form of a component.

- Define the measures and thresholds within which a component meets quality standards.

While these functions remain constant, the means of achieving them have evolved significantly. Traditionally, 2D drawings have been the cornerstone of engineering documentation. However, the emergence of 3D modeling and digital technologies has introduced more efficient and effective ways to fulfill these requirements.

2D Drawings: A Legacy Approach

In a 2D drawing, multiple views and dimensions are used to convey the geometric form of a component. Additional annotations and tolerances define the quality standards. While this method is familiar and widely adopted, it is time-consuming and prone to errors due to discrepancies between the drawing and the actual component. On average, creating a fully annotated 2D drawing requires over 8 hours of work.

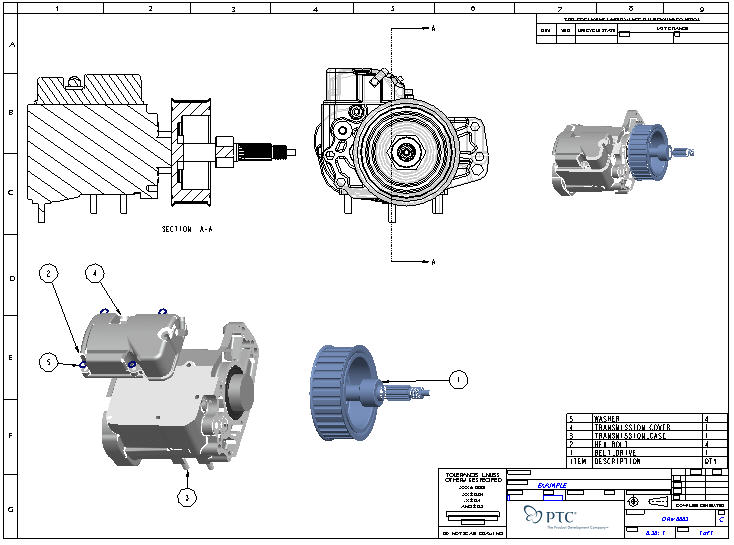

3D Models: A Digital Transformation

Conversely, a 3D model inherently defines a component’s geometric form through its geometry, eliminating the need for extensive 2D dimensions. Product Manufacturing Information (PMI) can be added directly to the 3D model to define quality measures, creating a fully annotated digital representation. Fully annotating a 3D model offers long-term benefits by reducing errors and improving downstream processes.

The Four Approaches to Engineering Documentation

Organizations have taken varying approaches to integrating 2D and 3D documentation, each with distinct trade-offs:

- Fully Annotated Drawings: The first method is a traditional method that uses 2D drawings exclusively, requiring significant time but offering familiarity.

- Minimally Annotated Drawings with 3D Models: This next method is a hybrid approach where the 3D model conveys geometry, and the 2D drawing provides tolerances and quality measures. This approach reduces time to 5 hours for drawings but risks discrepancies.

3. Fully Annotated 3D Models: This method offers a single source of truth that eliminates the need for separate 2D drawings, streamlining downstream processes and reducing errors.

4. Minimally Annotated 3D Models: The most efficient approach, leveraging inherent 3D geometry while adding only essential annotations, requires 6-7 hours on average.

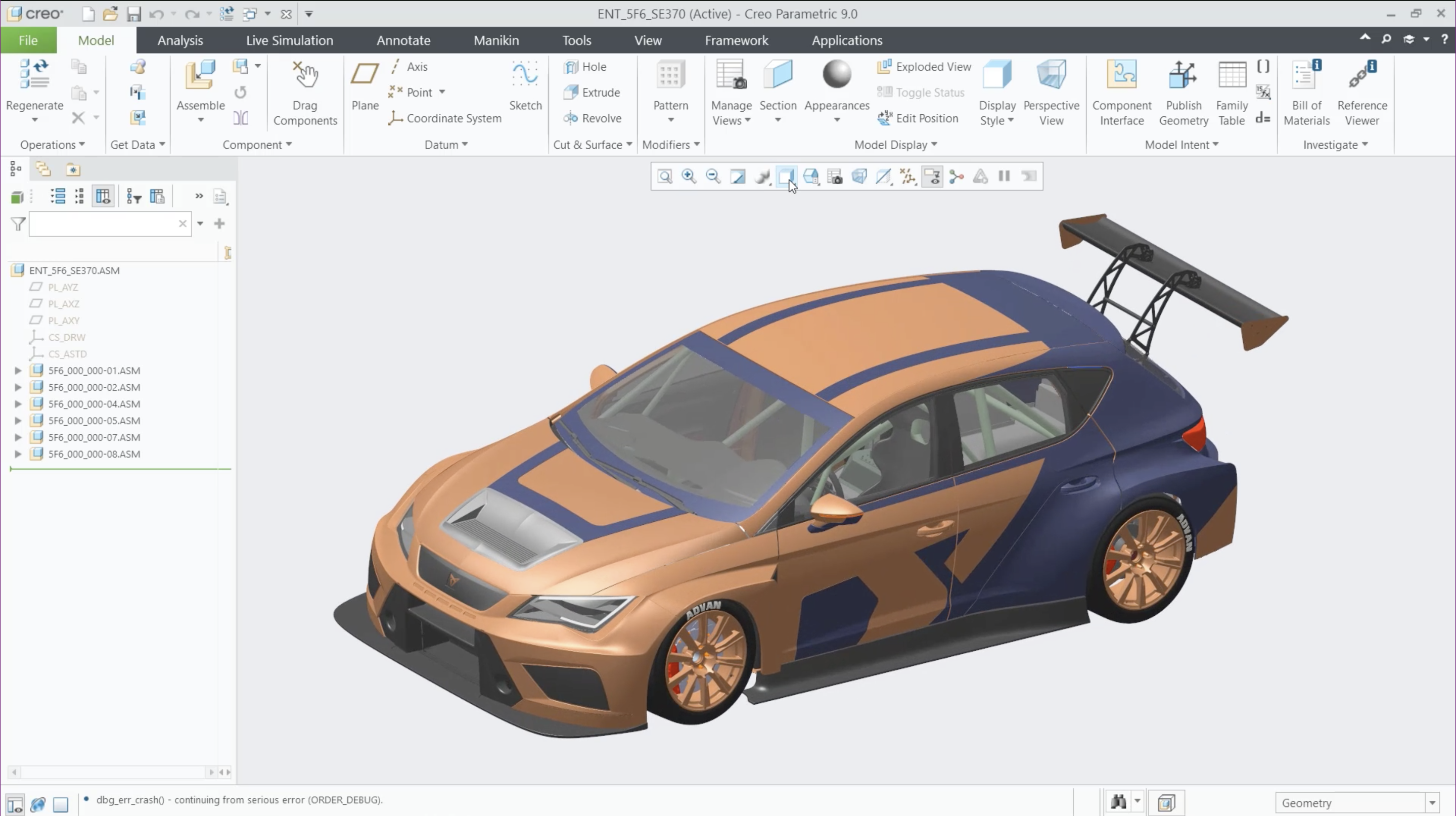

The ROI of Moving to Model-Based Definition

Organizations that choose to embed all the necessary information directly into their 3D CAD models, using them as the authoritative source of product definition, often receive many benefits. Let’s explore the ROI of shifting to this methodology.

Reduced Engineering Change Orders (ECOs)

Organizations embedding 3D models in their processes report 41% fewer ECOs. By providing a single, unambiguous source of truth, MBD eliminates the discrepancies that often lead to costly design changes. Tooling designers, machinists, and quality assurance teams can rely on accurate, consistent data, reducing miscommunication and rework.

Lower Scrap Rates

Companies leveraging MBD have reduced scrap by 47%. Traditional methods relying on 2D drawings often lead to errors in manufacturing due to misinterpretation or divergence between drawings and models. With MBD, manufacturers use machine-readable data directly from the 3D model, ensuring alignment and precision across operations.

Enhanced Productivity in Engineering

Transitioning to MBD also improves engineering productivity. Minimally annotated 3D models, which rely on inherent geometry and selective annotations, require 24% less time to create than fully annotated drawings. Engineering teams spend an average of 21 hours per week on documentation with MBD, compared to 24 hours for traditional methods.

Streamlined Manufacturing Instructions

Lastly, 3D models integrated into manufacturing instructions further enhance efficiency. Animated and annotated models enable operators to visualize complex sequences, reducing reliance on text-based instructions. Organizations embedding 3D models in production documentation experience fewer non-conformances and ECOs per project.

The Path to Model-Based Definition Adoption

Overcoming Barriers

Adopting MBD requires overcoming common issues such as executive buy-in and cultural change. Organizations that overestimate the ease of transitioning or underestimate the effort required risk project failures. Proper training, realistic expectation-setting, and a phased approach can mitigate these challenges.

Embracing the Cultural Shift

Some organizations adopt a “cultural compromise” by releasing both annotated 3D models and traditional 2D drawings. While this approach eases the transition, it undermines the full benefits of MBD by maintaining redundant documentation practices. It is best to fully embrace 3D models as the future of CAD.

Incremental Progress

MBD adoption is growing. The percentage of organizations exclusively relying on annotated 3D models doubled from 6% in 2014 to 12% today. Minimally annotated 3D models represent the most practical and beneficial approach, delivering ROI across engineering and manufacturing operations.

The Future of Model-Based Definition

Model-Based Definition is not just a technological advancement but a transformative strategy for modern enterprises. MBD offers undeniable ROI by reducing ECOs and scrap, improving productivity, and streamlining manufacturing. As adoption continues to grow, organizations embracing MBD are poised to outpace their competition in efficiency, cost savings, and product quality. If you would like to learn more about MBD adoption, contact our experts.