Industry 4.0 is revolutionizing how products are designed, produced, and delivered. At the heart of this transformation is smart factory design. Automation, data, and connected systems all come together to create highly efficient, flexible, and intelligent production environments. CAD in Industry 4.0 plays a pivotal role in enabling this vision, bridging the gap between virtual designs and physical reality. Let’s explore how CAD empowers smart factories, drives innovation, and shapes the future of manufacturing.

What Is Smart Factory Design and Industry 4.0?

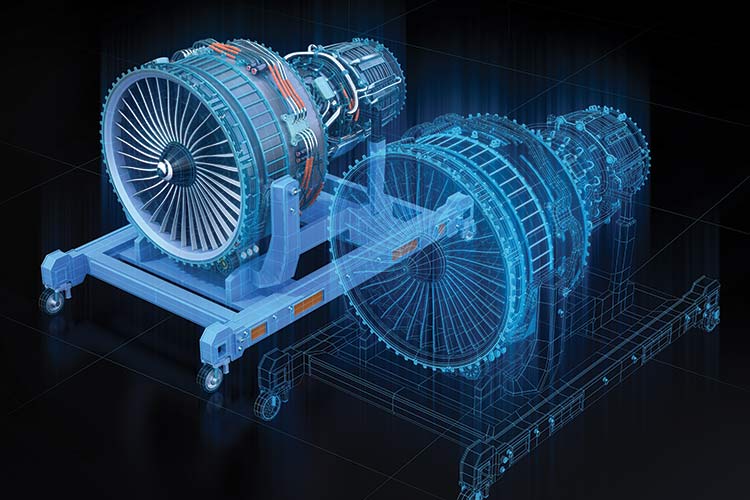

Industry 4.0, often referred to as the Fourth Industrial Revolution, represents the integration of technologies like the Industrial Internet of Things (IIoT), artificial intelligence, big data analytics, robotics, and cloud computing into manufacturing. The goal is to create smart factories where machines, systems, and humans communicate seamlessly. These tools enable real-time decision-making, predictive maintenance, and advanced automation. Smart factory design focuses on creating digital representations of these interconnected systems. These designs help optimize production layouts, workflows, and resource utilization before anything is built. CAD tools provide the foundation for this by enabling precise 3D models, simulations, and digital twins of factory assets and processes.

CAD for Industry 4.0: Automation, IoT, and Real-Time Data Utilization

IoT integration with CAD is at the core of modern smart factory success. They empower key Industry 4.0 technologies to drive efficiency and innovation. Through automation, CAD enables engineers to design and simulate complex systems such as robotic arms and conveyor networks. It ensures these components work together seamlessly before deployment.

Engineers can optimize their workflows and reduce errors through virtual testing with CAD. In addition to this, by linking CAD models with IoT sensors, manufacturers can create digital twins that mirror the physical factory in real time. These enable continuous monitoring of equipment performance, predictive maintenance, and fine-tuning of operations without interrupting production. As IoT devices stream data back to the digital twin, CAD models evolve alongside real-world conditions. This allows engineers to refine designs, improve layouts, and simulate new processes based on actual performance metrics. Together, CAD and IoT foster a dynamic, data-driven manufacturing environment where continuous refinement leads to maximum efficiency and precision.

Benefits of Applying the Principles of Industry 4.0

Integrating CAD in Industry 4.0 brings significant advantages such as improved productivity. By automating repetitive design tasks and simulating production flows, manufacturers can reduce downtime and accelerate time-to-market. CAD tools also provide enhanced customization. This enables manufacturers to adapt designs rapidly, supporting mass customization and on-demand production. Additionally, real-time monitoring and CAD-driven simulations help reduce defects, minimize material waste, and ensure compliance, resulting in higher quality products. Furthermore, efficient design processes, material optimization, and reduced energy consumption all contribute to more sustainable manufacturing.

PTC Creo with Industry 4.0

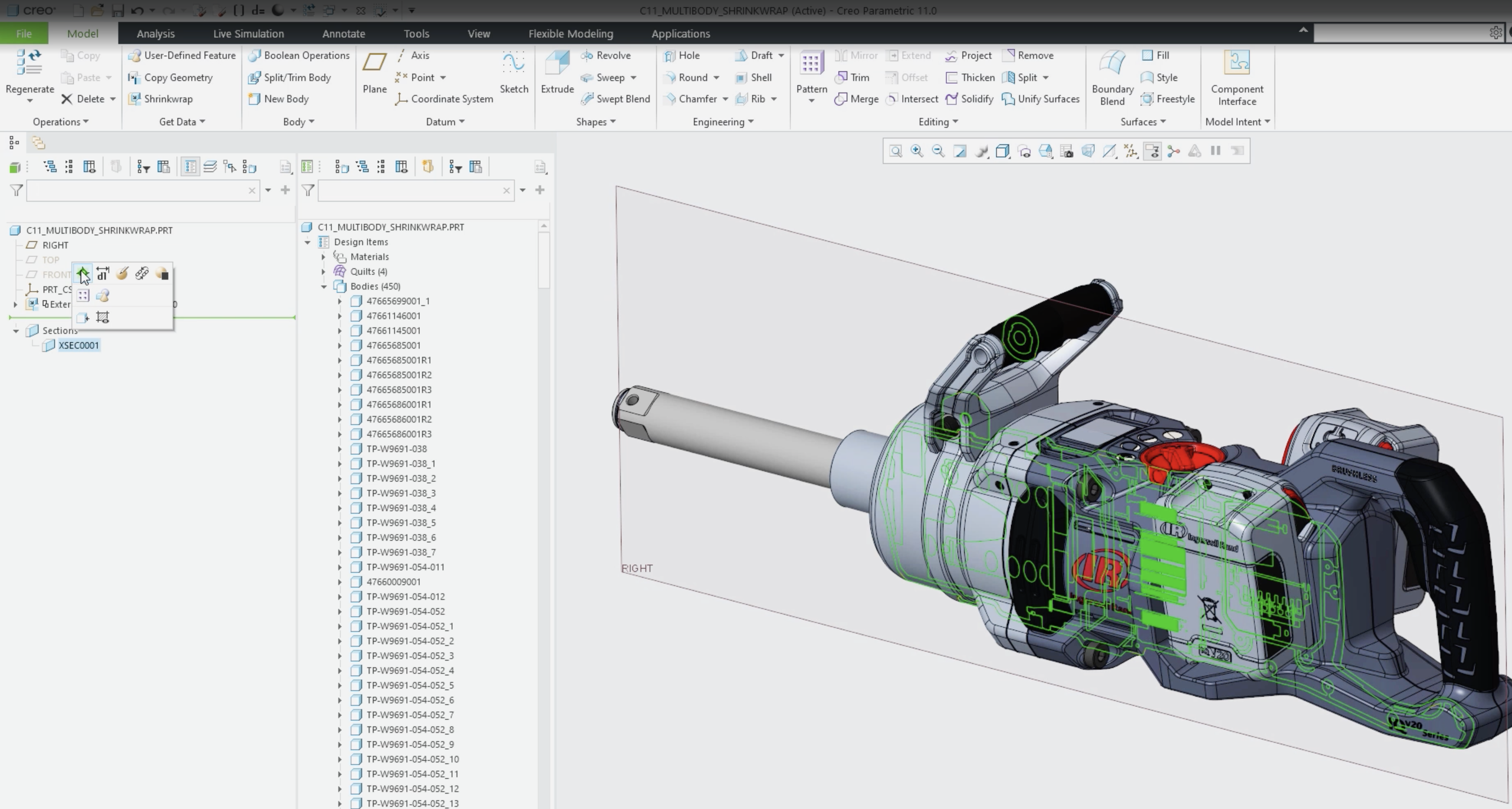

PTC Creo stands out as a leading CAD solution for manufacturers embracing Industry 4.0. It provides:

- Digital twin development – Creo’s precise 3D modeling and simulation capabilities support the creation of dynamic digital twins that connect seamlessly with IoT systems.

- Generative design and simulation – Powered by AI, Creo explores optimal design configurations within defined parameters, enhancing both innovation and manufacturability.

- Additive manufacturing support – Creo helps design parts ready for 3D printing, reducing material waste and supporting agile production.

- AR integration – Engineers can visualize designs in real-world contexts, improving collaboration and accelerating decision-making.

- Integration with PLM systems – Creo’s tight connection with PTC’s PLM solutions ensures that design data flows smoothly across the digital thread, aligning engineering with manufacturing and quality teams.

With these capabilities, Creo equips manufacturers to fully leverage Industry 4.0 principles and build smarter, more adaptive factories. It is also important to note that Creo may run on vCAD or users may choose Creo’s SaaS option, Creo+ which both allow teams to work from anywhere.

The Future of Industry 4.0 and Smart Factory Design with CAD

As Industry 4.0 technologies continue to advance, CAD in Industry 4.0 will become even more powerful and interconnected. The future promises AI-enhanced design suggestions, deeper digital twin integration, AR/VR-powered collaboration, and smarter supply chains. CAD systems will increasingly offer real-time recommendations based on machine learning insights from operational data. Additionally, live factory data will continuously update CAD models, allowing immediate validation of design changes and performance impacts. Immersive design reviews and virtual training environments will improve stakeholder alignment and workforce readiness. Furthermore, CAD-linked digital threads will extend beyond the factory floor to suppliers and partners, enabling end-to-end visibility and optimization.

CAD for The Future

In the era of Industry 4.0, CAD is more than just a design tool. It is a critical enabler of smart factory design. By integrating CAD and IoT, manufacturers can unlock the full potential of automation, connected systems, and real-time data. With these tools, they can build factories that are not only more efficient but also more flexible and sustainable. Solutions like PTC Creo are at the forefront of this transformation, helping companies design, simulate, and optimize their smart factories for today’s challenges and tomorrow’s opportunities. Contact us today to learn how we can help you harness the power of CAD for your Industry 4.0 journey.