With constant pressure to deliver high-quality products, Model-Based Definition (MBD) has emerged as a game-changer. MBD is particularly useful for companies aiming to achieve precision manufacturing and meet compliance regulations. By using MBD in CAD, manufacturers can eliminate inefficiencies, reduce errors, and ensure a single source of truth throughout the product development cycle. Let’s explore why MBD is essential for compliance and why solutions like Creo are leading the way in making this transformation possible.

Why We Need MBD for Compliance

Traditional 2D drawing-based processes are no longer sufficient for quickly achieving compliance and precision. Modern manufacturing environments need more, and here’s why:

- Inefficiency of 2D workflows: 2D drawings are time-consuming to create and maintain. Updating a 2D drawing often requires redundant effort to recreate information that already exists in the 3D model. This is increasing the risk of unnecessary inconsistencies.

- Out-of-sync documentation: Tolerances, GD&T, and other manufacturing information can easily become disconnected between 2D drawings and 3D models as well. This creates compliance risks and manufacturing errors.

- Difficulty in visualization: 2D drawings can be harder for shop floor teams and suppliers to interpret accurately, increasing the likelihood of miscommunication and mistakes that impact both compliance and product quality.

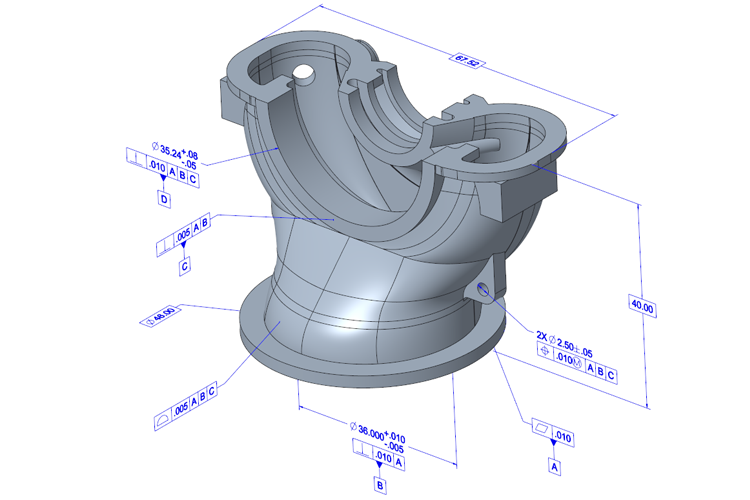

By defining Product and Manufacturing Information (PMI) directly within the 3D model, MBD in CAD creates a single source for geometry, tolerances, notes, and annotations. This single source of truth is essential for satisfying regulatory frameworks that mandate clear product definitions.

Overcoming Objections: The Case for Moving from 2D to 3D

Despite the clear advantages, many organizations are slow to abandon 2D drawings. Their reasoning is understandable. The first being that 2D drawings are deeply ingrained in the product development process. They are often seen as the legal master for manufacturing and inspection. In addition to this, procurement, contracts, and quality teams are familiar with referencing 2D prints for quotes and inspections. Lastly, change management can be daunting when processes have relied on 2D documentation for decades.

However, moving from 2D drawings to 3D models brings transformative benefits. Firstly, engineers, suppliers, and manufacturers gain a clearer understanding through rich 3D data. This data can be interrogated from any viewpoint, which dramatically reduces misinterpretation. Additionally, a single model eliminates the need to manage separate 2D assets. 3D models save time and reduce the chance of discrepancies. Furthermore, automated manufacturing processes can directly consume software-readable PMI, enabling smarter, faster production. The shift to MBD is a critical step in the digital transformation of manufacturing, helping teams reduce rework, enhance precision, and maintain compliance.

Creo as a Complete MBD Solution

PTC Creo provides a comprehensive suite of tools that make adopting MBD in CAD both practical and powerful. As a leader in 3D CAD solutions, Creo helps companies replace 2D drawings with 3D models that serve as the complete definition of a product, including all PMI.

Key MBD capabilities in Creo include:

- Creo Parametric: Provides standard 3D annotation tools for defining and managing PMI within the model itself.

- Creo GD&T Advisor (Basic & Advanced): Supports correct, standards-based creation and validation of GD&T annotations.

- Creo EZ Tolerance Analysis: Helps analyze tolerances to improve quality and reduce manufacturing costs.

- Creo View: Allows easy access to 3D models and PMI for downstream teams, including manufacturing and quality.

Importantly, while GD&T Advisor and Tolerance Analysis enhance Creo’s MBD capabilities, they’re not required for implementing MBD in CAD. Creo’s flexible platform allows teams to adopt MBD at their own pace, supporting compliance and precision. In addition to this, Creo helps support sustainability efforts, which can also aid in achieving compliance.

MBD for Compliance and Precision

The benefits of adopting precision manufacturing and ensuring compliance with MBD are substantial. This approach reduces time-to-market by eliminating the need for separate 2D drawings and redundant documentation. Product quality also improves as errors caused by misinterpretation and manual data re-entry are minimized. Additionally, collaboration is enhanced through the availability of a complete digital product definition that stakeholders can access anytime, anywhere. Furthermore, costs are lowered by automating manufacturing with software-readable PMI. This reduces the need for human intervention and associated expenses. Finally, compliance is strengthened by ensuring accurate and consistent product definitions that meet regulatory requirements and withstand audits.

Precision Manufacturing with MBD

Model-Based Definition (MBD) has become a necessity for manufacturers. By moving beyond 2D drawings and adopting MBD in CAD, companies can create a single source of truth that drives smarter decisions, clearer communication, and better products. Creo’s complete MBD solution helps teams achieve compliance with rigorous standards while enhancing precision and efficiency. It gives teams the tools they need to succeed in today’s complex manufacturing environment. If you’re ready to simplify compliance, contact us today to learn how we can help you implement precision manufacturing with MBD using Creo.