Manufacturers are under more pressure than ever to improve quality, reduce waste, and keep pace with rapidly shifting production demands. However, traditional MES and inspection systems often fall short due to their rigidity, slow updates, and disconnection from real-world frontline needs. Modern teams require agility, intelligent automation, and real-time decision making. This is where composable manufacturing and AI-enabled frontline operations come together. With Tulip’s Frontline Operations Platform, manufacturers can quickly build flexible, modular systems that reduce scrap and improve quality across the entire production process. Tulip empowers teams to detect problems earlier, prevent defects, and continuously improve operations at scale.

Composable Manufacturing with Tulip

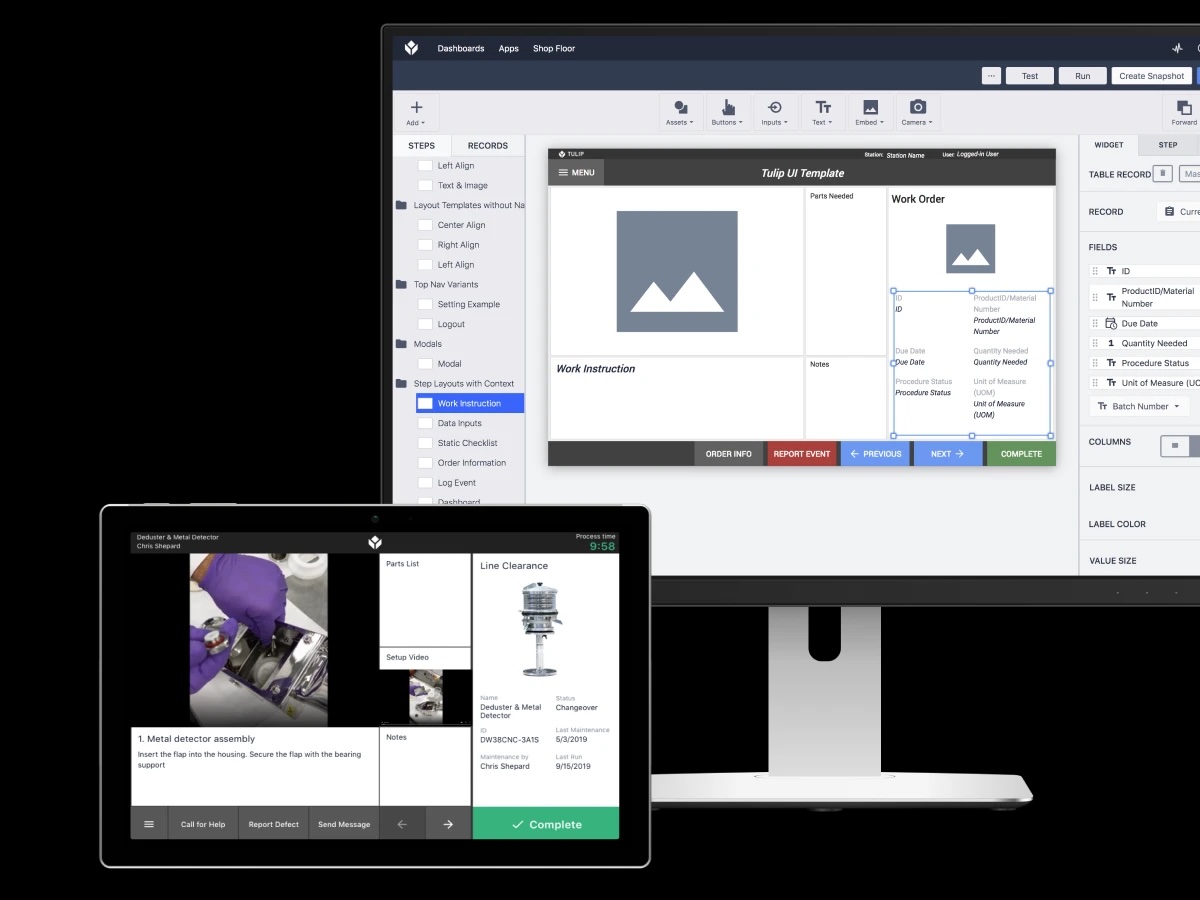

Composable manufacturing transforms how teams design, operate, and evolve production systems. Instead of relying on a large, monolithic MES, manufacturers can assemble modular building blocks that work together in a flexible architecture.

Tulip provides everything needed to create a composable ecosystem. No-code app building allows frontline engineers to rapidly design and iterate workflows, inspection steps, and visual guides without slowing down production. Open connectivity links machines, sensors, cameras, and enterprise systems so that data flows across the entire value stream. In addition to this, built-in analytics and a custom data model provide real-time visibility into OEE, cycle times, quality trends, and scrap drivers. Furthermore, Tulip provides a world-class ecosystem of 300 apps, 60 connectors, and 700 drivers. These accelerate deployment, standardize best practices, and help teams scale across sites.

Tulip’s Composable MES App Suite pushes this approach even further. With downloadable apps for production management, inspection, eBR, logbooks, and more, teams can quickly establish a foundation for operations and extend it as the business grows. It is designed for continuous transformation, where every improvement cycle builds on the last.

Tulip’s AI Capabilities

Tulip is leading the industry with AI and vision capabilities designed for frontline operations. These tools help manufacturers eliminate manual errors, detect anomalies sooner, and capture decision-ready insights without needing data science expertise.

Key AI capabilities include:

- Vision tools verify correct part selection, detect defects, read labels, and streamline quality checks.

- AI Composer turns SOPs and work instructions into interactive, step-by-step apps in minutes, reducing development time by up to eighty percent.

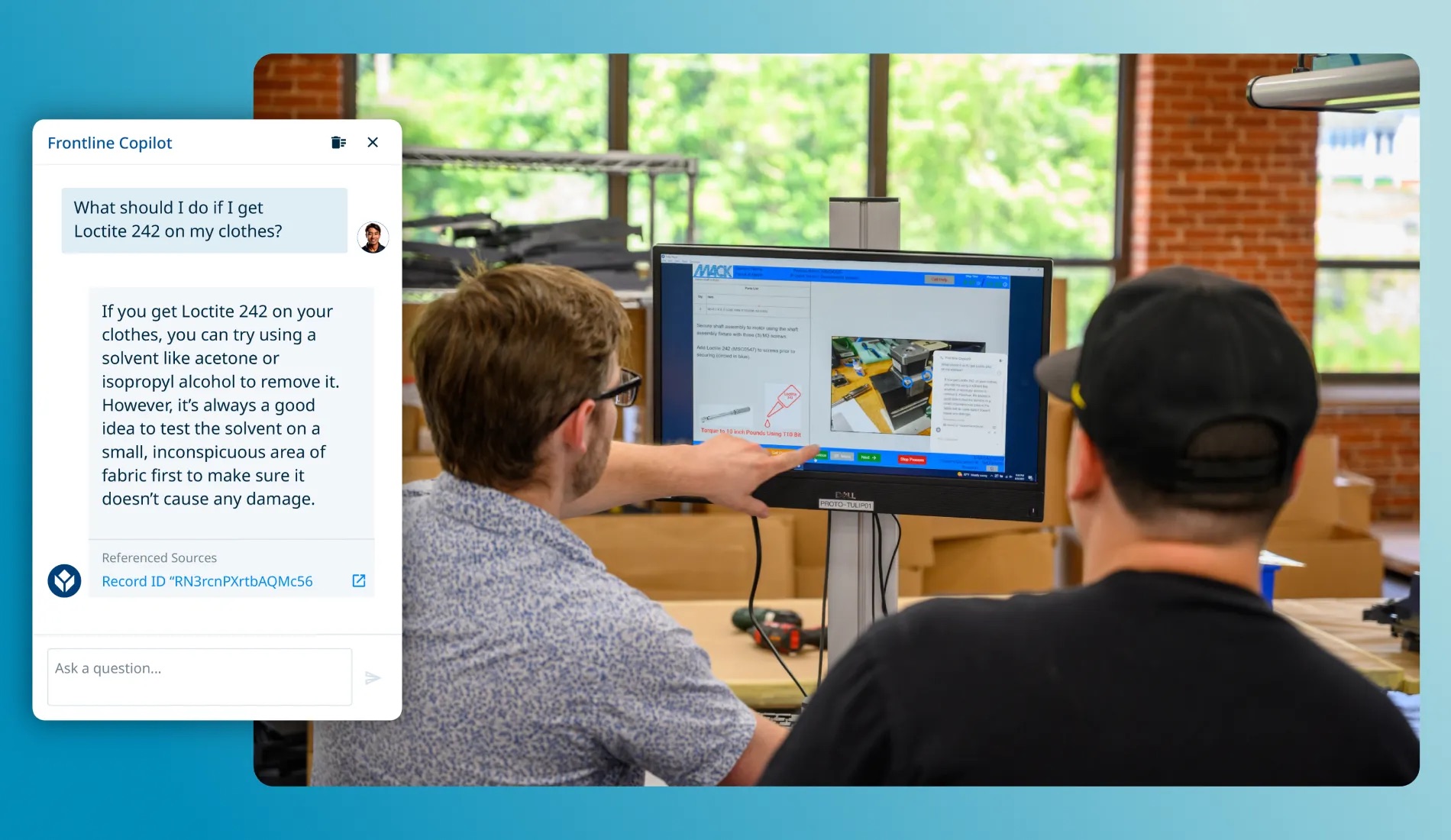

- Frontline Copilot lets operators chat with manuals, SOPs, datasheets, and production records, reducing issue resolution time and improving decisions.

- AI Prompt Actions embed AI directly into workflows. Teams can categorize defects, summarize performance changes, and trigger alerts using LLM responses.

- AI Insights let teams ask questions about production data, generate charts, and uncover trends without writing a single query.

- AI Translation for fast multi-language deployment across global facilities.

- Model Context Protocol (MCP) lets AI agents take action in Tulip, supporting tasks like analyzing trends, creating data tables, and setting up station interfaces.

Together, these tools make AI accessible to any manufacturer. It allows teams to deploy ML, vision, and LLM-powered insights directly at the point of work.

Improving Quality and Reducing Scrap with AI and Vision

Quality and scrap reduction depend on early detection, consistent process execution, and fast feedback loops. Tulip’s AI and vision capabilities strengthen all three. Vision verifies that operators pick the right components and follow the correct steps. This essentially error-proofs workflows, reducing kitting, assembly, and packaging mistakes. Additionally, Tulip provides a faster root cause analysis with AI Insights and custom chats. These tools help engineers quickly explore defect patterns, understand production variances, and identify common failure modes. Furthermore, AI Prompt Actions categorize defects and recommend corrective actions. This automates the defect classification process, reducing rework and improving first-pass yield.

Intelligent Document Processing (IDP) provides more accurate data capture. It extracts data from labels and travelers, reducing transcription errors that lead to nonconformance. Interactive apps guide operators through standard work reliably and ensure quality checks are completed consistently. This ensures real-time compliance. Manufacturers may also perform predictive quality checks to alert teams to risk conditions and then adjust processes before scrap accumulates.

These capabilities directly reduce scrap, prevent defects from cascading, and shorten the time it takes to spot and resolve quality issues. Manufacturers consistently see results, such as 75% less training time, 59% fewer kitting errors, and up to $500,000 in annual savings from digitized logbooks and inspections.

SPK and Associates x Tulip

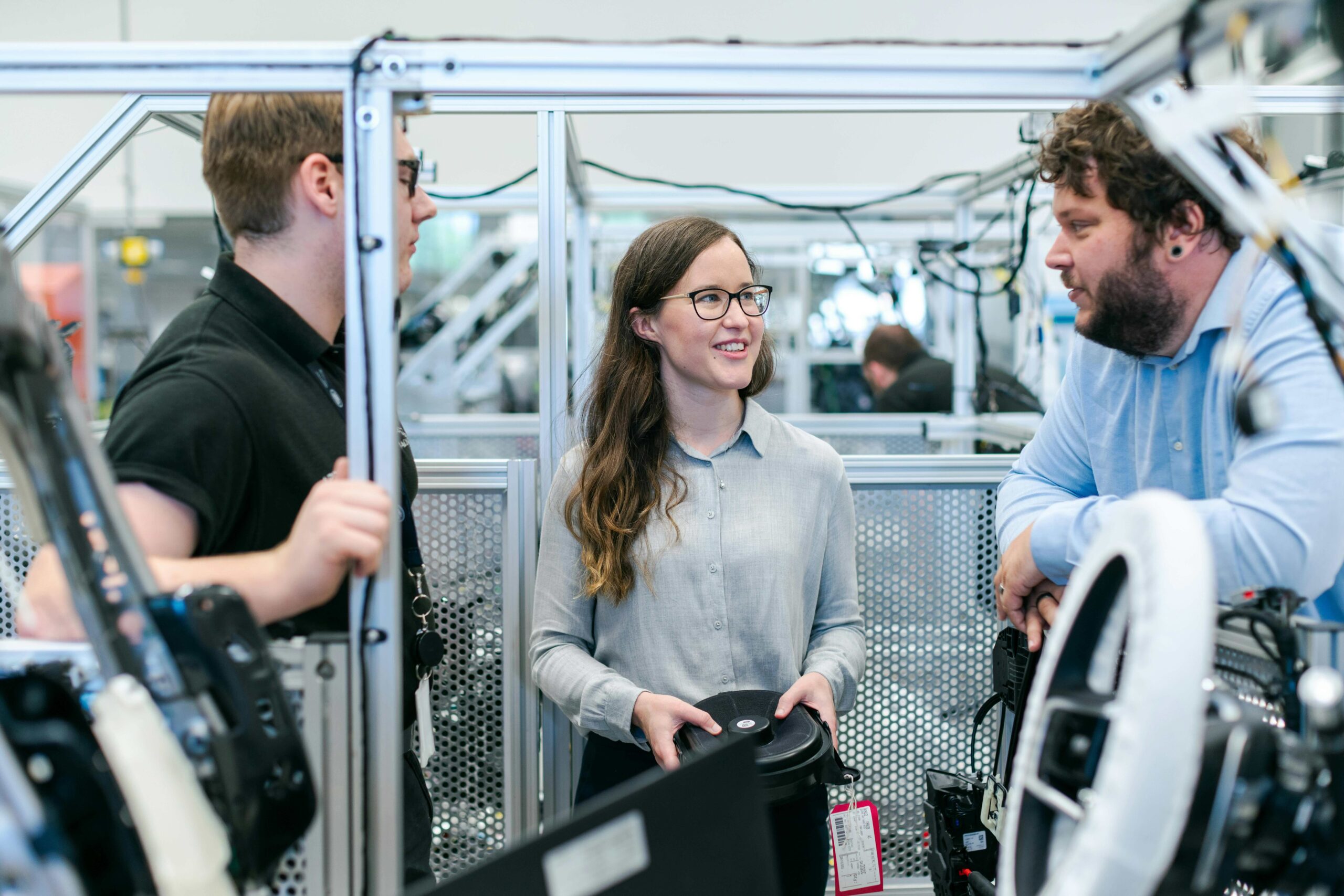

SPK and Associates partners with manufacturers to deploy Tulip as the foundation for a composable, AI-enabled production system. Our team brings deep experience in regulated industries, digital manufacturing transformation, MES strategy, and shop floor integration.

We help manufacturers:

- Assess current processes and identify scrap, rework, and quality improvement opportunities.

- Deploy the Composable MES App Suite with templates for inspection, materials, production management, eBR, and logbooks.

- Integrate Tulip with existing equipment, sensors, enterprise systems, and cloud platforms.

- Implement AI tools such as vision, AI Composer, and Frontline Copilot to accelerate digital adoption.

- Build scalable, governed architectures that support continuous improvement across sites.

- Establish a repeatable Composable Manufacturing Transformation playbook that supports future projects, quick wins, and global expansion.

Together, SPK and Tulip enable a rapid shift from rigid, traditional MES to flexible, AI-powered operations that drive measurable quality and productivity outcomes.

Improving Quality And Reducing Scrap with Tulip

Reducing scrap and improving quality requires a modern approach that blends human expertise and AI-driven insights. Tulip’s composable manufacturing platform brings these elements together so manufacturers can move faster and eliminate waste at the source. With powerful AI tools and flexible no-code apps, teams can transform frontline operations in days instead of months. Partnering with SPK accelerates this transformation. We help you design, deploy, and scale Tulip so you can build a long-term, intelligent operations strategy. Contact us today to unlock a new level of agility, visibility, and operational excellence.