CAD engineers and product designers rely on powerful tools to turn innovative ideas into a manufacturable reality. Two CAD systems, PTC Creo and Dassault Systèmes SolidWorks, stand at the forefront of this landscape. Each tool offers a suite of features tailored for precision, speed, and flexibility. While both platforms bring value to engineering workflows, it can be argued that one may be the more forward-looking solution. Let’s explore the benefits and drawbacks of Creo and Solidworks for organizations tackling complex projects and large assemblies.

Main Differences Between Creo and SolidWorks

At their core, SolidWorks and Creo share the same mission: to provide engineers with the capabilities to design high-quality parts and assemblies efficiently. However, the two differ significantly in approach and technical depth.

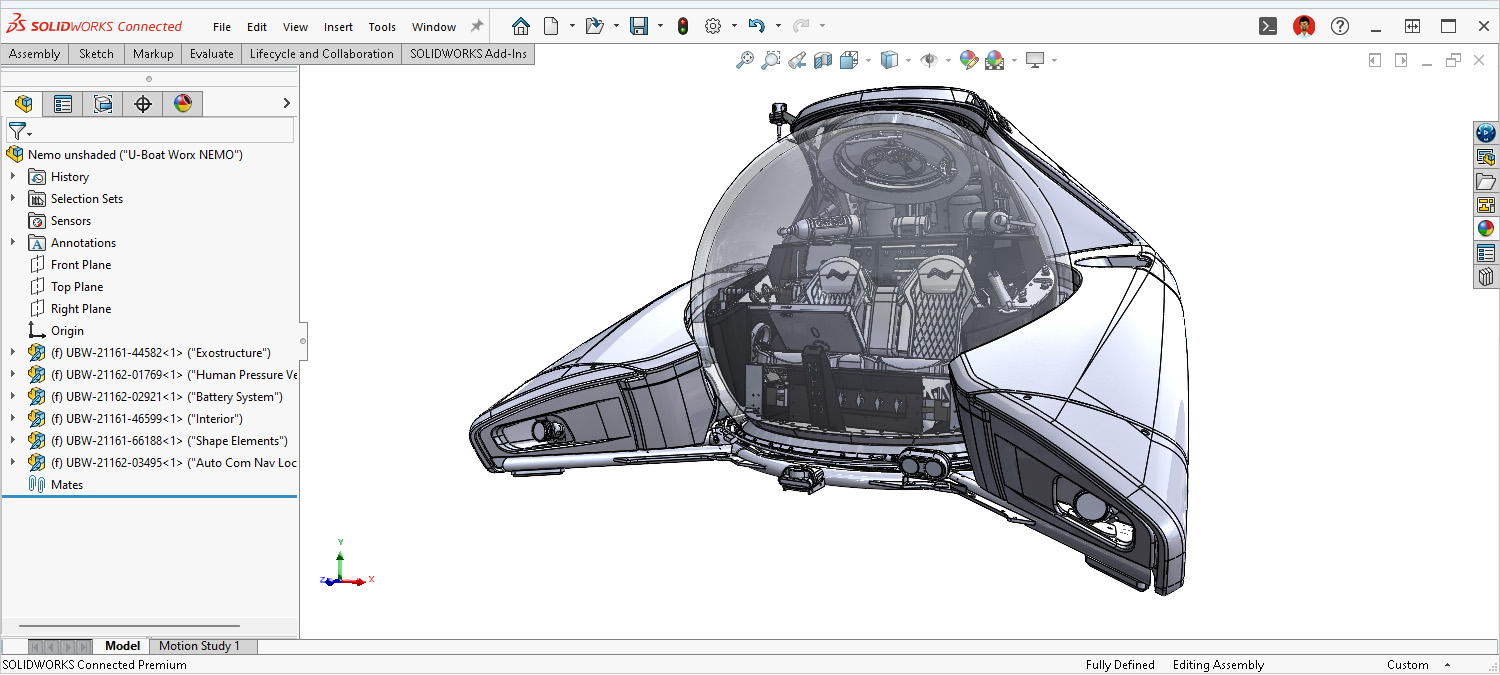

SolidWorks is often recognized for its user-friendly interface and ease of learning, making it a popular choice for mid-sized teams and projects with less complex product designs. It excels in general engineering tasks and offers a smooth onboarding experience for new users. It remains a reliable and efficient solution for many product development needs.

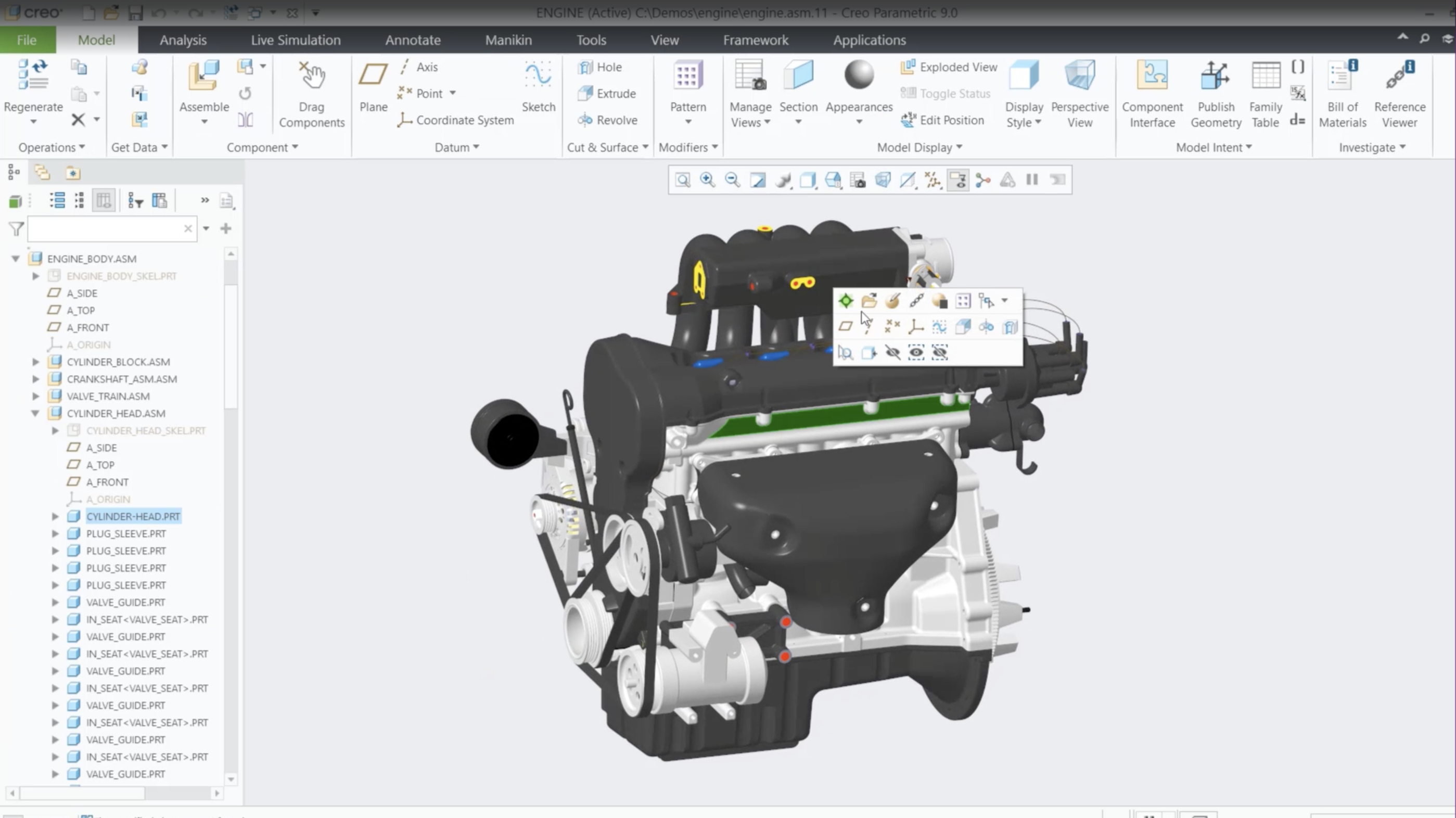

Creo excels in scalability and power. Its robust modeling engine handles large assemblies and intricate geometry with ease, making it the go-to choice for industries like aerospace, automotive, and advanced manufacturing. Creo’s combination of parametric, direct, and freestyle modeling offers unmatched flexibility. Not to mention, it handles late-stage design changes without disruption, which is a crucial advantage for dynamic product development environments. Additionally, Creo ensures backward compatibility, a major benefit for companies managing legacy files. Creo also integrates natively with the broader PTC ecosystem, including Windchill PLM and ThingWorx, providing a foundation for the digital thread.

Recent Innovations in Creo and SolidWorks

Here’s a snapshot of how SolidWorks and Creo stack up when it comes to recent innovations:

Benefits and Drawbacks of SolidWorks and Creo

SolidWorks offers several advantages that make it a strong choice for teams seeking a straightforward and efficient design tool. Its easy-to-learn interface supports quick onboarding, allowing new users to become productive with minimal training. The platform benefits from a large user community and an extensive third-party plugin ecosystem. It provides a wide range of resources and customization options. SolidWorks is particularly well-suited for basic modeling tasks, offering streamlined tools for rapid 2D drafting and prototyping. Additionally, its intuitive workflow and accessible feature set make it ideal for teams that prioritize speed and simplicity in their product development processes. However, it is not the best choice for large teams with complex workflows.

On the other hand, Creo stands out for its robust capabilities in handling complex product designs and large assemblies. It offers top-down design approaches and simplified representations that maintain performance at scale. Its seamless design flexibility supports everything from freestyle concepting to detailed parametric refinement, making it adaptable across the full spectrum of design workflows. Creo also includes built-in support for emerging technologies such as generative design, augmented reality (AR), model-based definition (MBD), and additive manufacturing. Backward compatibility ensures long-term value by preserving access to legacy design data. Meanwhile, strong tools for managing late-stage design changes provide the agility needed for fast-paced development cycles. Additionally, Creo offers scalable simulation and analysis features, enhanced further by integration with Ansys, empowering teams to validate and optimize designs with confidence. Due to its extensive capabilities and engineers often learning Solidworks in school, Creo may take longer to onboard.

Which Solution Do We Suggest?

While SolidWorks continues to be a reliable choice for smaller teams and less complex projects, Creo leads the CAD industry when it comes to high-performance engineering, digital transformation readiness, and future scalability. Whether you’re creating consumer electronics, automotive components, or aerospace assemblies, Creo offers the depth and breadth to scale with your product complexity and future needs. Creo is engineered for professionals who demand more from their CAD tools. Due to these features and its integration capabilities, we commonly recommend Creo to our clients. However, SolidWorks is a great choice for teams that do not need all the bells and whistles. If your organization is looking to accelerate design cycles, improve precision, and embrace the future of engineering, Creo is the tool to make it happen. If you are interested in discovering what Creo can unlock for your team, contact our experts today.