Accelerating product development, improving product quality, and enhancing collaboration are all main priorities for designers and manufacturers. Achieving these goals requires the proper digital solutions for managing product data and processes. Product Lifecycle Management (PLM) and Product Data Management (PDM) systems are the most commonly adopted solutions. While they share some overlapping functions, they serve very different purposes. In this blog, we’ll explore the key differences between PLM and PDM, the strengths of each, and how to determine which solution best fits your organization’s size, complexity, and collaboration needs.

What Is PLM?

Product Lifecycle Management (PLM) is a strategic approach to synchronizing an organization’s people, processes, business systems, and data. Its goal is to optimize every phase of a product’s lifecycle. By adopting PLM, enterprises can gain a holistic view of their product development. Additionally, they can ensure that every stage is seamlessly managed and integrated from concept to post-manufacturing maintenance.

Key Functions of PLM

PLM systems deliver a broad range of functionalities that extend beyond the engineering department. These systems facilitate enterprise-wide collaboration and ensure that every stakeholder remains aligned. Here are some of the core functions of PLM:

- Cross-Functional Collaboration:

PLM breaks down silos by connecting departments such as engineering, manufacturing, marketing, and service. It promotes a unified approach to product development and lifecycle management.

- End-to-End Process Management:

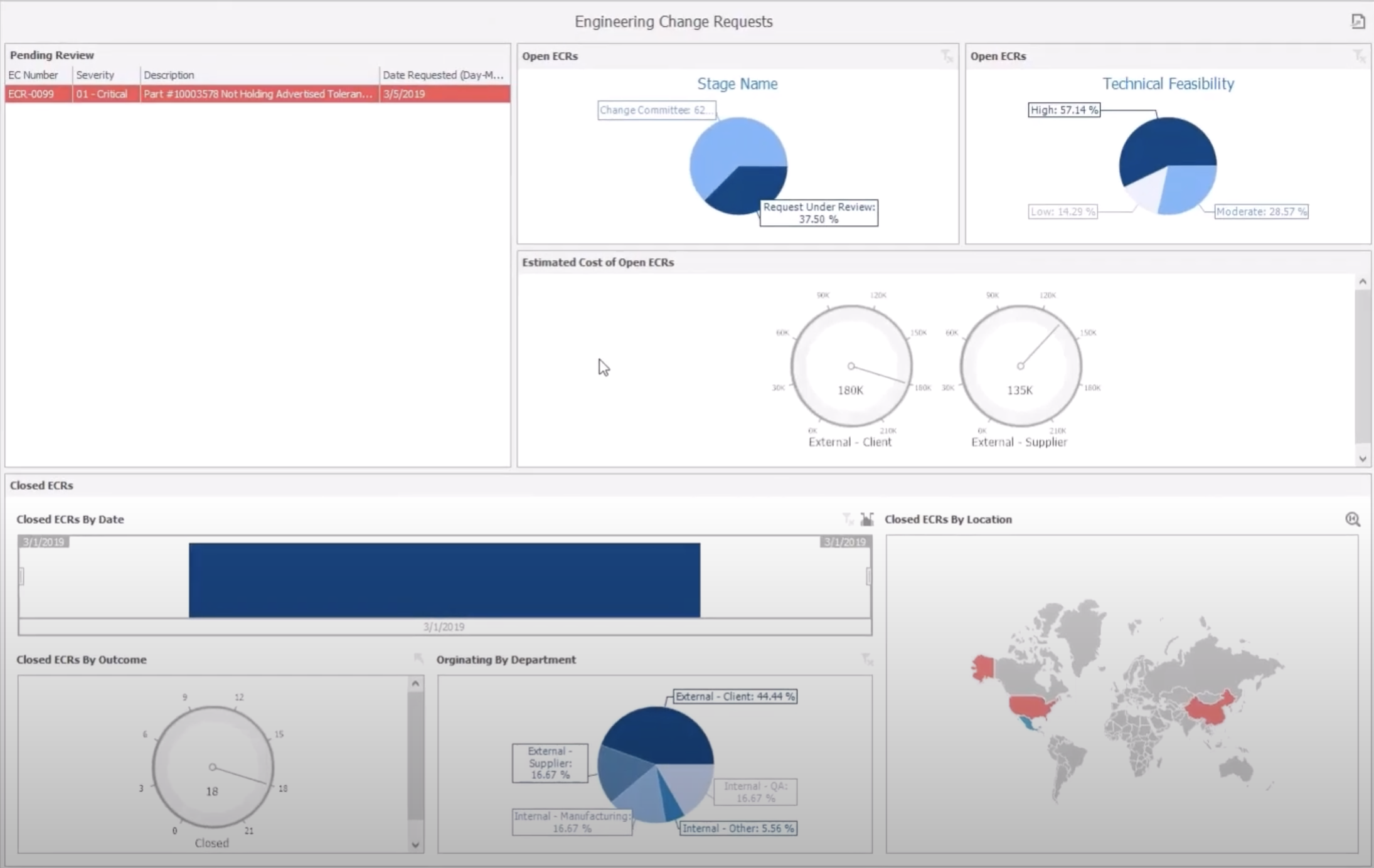

Whether it’s the initial design, simulation, compliance checks, or quality control, PLM oversees every aspect of the process. This comprehensive management helps in identifying inefficiencies and optimizing the overall workflow. - Change and Configuration Management:

PLM systems offer robust change control mechanisms to keep up with evolving products. Products are consistently updated due to responses to market feedback and technological advances. The change control mechanisms ensure that any updates or modifications are systematically tracked and implemented.

- Requirements Tracking & Systems Engineering:

Linking product requirements directly to design and manufacturing processes helps ensure that every product meets both market and regulatory standards. - Bill of Materials (BOM) and Lifecycle State Control:

PLM tools manage detailed BOMs throughout the product lifecycle, from initial specifications to the final product, enabling better inventory control and cost management.

- Workflow Automation:

Automated workflows not only speed up processes but also reduce human error, ensuring a smoother path from product conception to market launch. - Project and Portfolio Management:

Modern PLM systems integrate project management capabilities, allowing organizations to manage multiple projects simultaneously. - Seamless Tool Integration:

PLM systems are designed to interconnect with other critical business systems, including ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), CAD (Computer-Aided Design), and supply chain management tools. This integration helps maintain continuity and consistency of data across the enterprise.

What is PDM?

While PLM offers an umbrella solution covering the full lifecycle of a product, Product Data Management (PDM) is a more focused subset designed primarily for engineering teams. PDM revolves around managing the intricate details of product data, especially around CAD files and related documentation.

Key Functions of PDM

PDM systems offer specialized features that cater to design teams looking to manage technical data securely and efficiently:

- Central Repository for Product Data:

PDM solutions provide a secure and centralized location for storing CAD models, drawings, and technical specifications. They ensure that the most recent version of any design is easily accessible.

- Version and Revision Control:

Keeping track of every change made to a design is critical in a fast-paced development environment. PDM systems meticulously manage versions and revisions, which helps prevent confusion and versioning conflicts. - Access and Permissions Management:

By managing who has access to sensitive design data, PDM tools ensure that only authorized personnel can make changes, thereby enhancing data security.

- BOM Management:

Although more basic than PLM’s capabilities, PDM handles essential BOM management for design-related data. This ensures that the products are built according to specification. - Streamlined Workflow for Approvals:

PDM systems automate workflows for design approvals and engineering change orders. This helps speed up the overall process and ensures traceability through detailed audit trails for compliance.

PLM vs. PDM: A Comparative Analysis

Understanding the scope and functions of both systems helps in determining which tool best meets the needs of an organization. Below is a comparative breakdown of key aspects:

When to Use Each Tool

While both PLM and PDM significantly impact product development, their benefits extend differently across business functions. While PDM is cheaper, easier to maintain, and typically needs less training, PLM improves visibility and efficiency and prevents more mistakes.

Use PDM When:

- The focus is on managing engineering data.

- There is a need for robust CAD file management with reliable version control.

- The company comprises small to medium-sized teams without extensive cross-departmental collaboration.

- A quick and straightforward deployment is a priority, minimizing operational disruption.

Use PLM When:

- The objective is to establish enterprise-wide collaboration and integration.

- Managing the complete product lifecycle across multiple business functions is essential.

- Products are complex, or the operating environment is heavily regulated.

- There is a need to align strategies across product design, quality control, and delivery processes.

PLM vs. PDM: Aligning Your Strategy with the Right Solution

In summary, while both PLM and PDM play critical roles in product development, understanding their distinct scopes is essential for strategic implementation. PDM is best suited for teams focused on managing complex design data and ensuring precision in engineering workflows. On the other hand, PLM serves as a broader, enterprise-wide solution designed to drive strategic innovation, efficiency, and seamless collaboration across all departments. By carefully evaluating your organization’s specific needs, product complexity, and collaboration requirements, you can choose the tool that best aligns with your operational and strategic objectives. If you would like to discuss this topic further or need information on solutions, contact our experts.