PTC Integrity Lifecycle Manager and PTC Windchill are two enterprise level applications that many large companies have invested in as part of their product development environment. Often time’s companies will use PTC Integrity Lifecycle Manager to handle the software components of their new product development, while using PTC Windchill to manage the hardware aspects of the development process. PTC Integrity Lifecycle Manager is good for handling requirements, test artifacts and software modules and PTC Windchill is often used to handle full documents, CAD documents, and other artifacts more closely related to hardware development.

At some point though, if you have both systems in place you want to be able to bring resources from both together. This is what the PTC Integrity to Windchill Integration is all about. In this blog article I will provide a brief overview of the PTC Integrity to Windchill integration, what it does and what it doesn’t do.

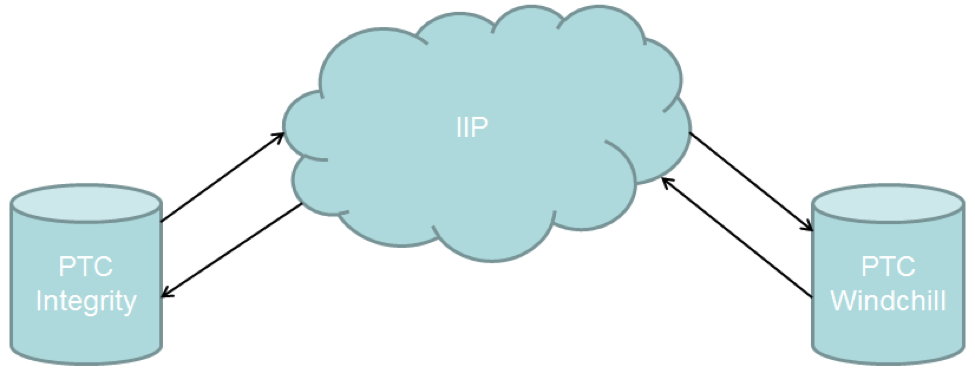

The PTC Integrity to Windchill Integration is built upon the PTC Integrity MIIP2 integration platform. The intent of this integration is to pick up documents authored in PTC Integrity Lifecycle manager and move them into Windchill. The following diagram illustrates this process:

The process works as follows:

- A document, created within one of the supported document domains within PTC Integrity Lifecycle Manager is identified as something that should be sent to Windchill. The user, within PTC Integrity Lifecycle Manger identifies the destination location of the document should be placed within PTC Windchill.

- The actual process to move the document is kicked off by saving the Windchill destination and setting the “Send to Windchill” flag. The Integrity document is then picked up and set to an intervening server process running the Integrity Integration Platform.

- The Integration server then maps the Integrity document into a Windchill artifact.

- The new Windchill artifact is then written to the Windchill server.

- Upon the successful completion of the transaction, the status of the transaction is sent back to PTC Integrity, via the Integration server, along with the final location information.

- The PTC Integrity document is updated accordingly.

This integration was built by PTC when PTC Integrity Lifecycle Manager was originally brought into the PTC family of products. Currently this is the only officially support integration between the two environments. That being said there are a number of limitations with this integration that should be known about up front. The limitations are:

- All documents sent through the integration must be authored in PTC Integrity Lifecycle Manager before they can be pushed into Windchill. There is no provision for authoring a document in Windchill and pushing it to PTC Integrity Lifecycle Manager.

- Any changes in content to a document must take place within PTC Integrity. Documents pushed from PTC Integrity Lifecycle Manager are locked, and as such changes are not permitted.

- The original integration was designed to work with the ALM Solution. The integration can be re-configured to work with other solutions like the Medical Device Solution.

Basically these limitations will force you to, when it comes to products managed though PTC Integrity, maintain your Integrity system as the “System of Record” for all those documents.

As you can see, despite the limitations, this integration provides a tested and supported method of exchanging documents between PTC Integrity Lifecycle Manager and PTC Windchill.

Next Steps:

- Contact SPK and Associates to see how we can help your organization with our ALM, PLM, and Engineering Tools Support services.

- Read our White Papers & Case Studies for examples of how SPK leverages technology to advance engineering and business for our clients.