File mistakes and unnecessary rework remain all too common in the engineering space. Inefficient CAD file management due to poor collaboration and hardware limitations can result in missing details or time-consuming corrections. This is why reducing CAD errors is so critical. By adopting efficient practices and the proper tools, engineering teams can meet deadlines, avoid cost overruns, and maintain customer satisfaction. Let’s explore the best ways to minimize rework in CAD.

Common CAD File Errors

CAD environments are complex, and errors can arise at any stage of the design cycle. The most frequent include:

Missing or Incorrect Measurements

Missing or incorrect measurements cause issues during manufacturing, construction, or downstream use. Even one missing measurement can derail production and require costly redesigns.

Mislabeled Layers

Inconsistencies in layering and organization make files confusing and error-prone. When critical details are hidden, buried, or simply incorrect, engineers may make the wrong assumption or miss required modifications.

Inefficient Data Preparation

Preparing files for other teams, such as converting models for simulation or manufacturing, takes extra effort if workflows are disconnected.

User Inefficiency

Engineers who don’t use shortcuts, macros, or customization often take far longer to complete tasks. Multitasking can also lead to issues due to a lack of focus. It can lower accuracy and slow delivery.

Unmanaged Complexity

Complex assemblies and frequent design revisions create a greater chance for errors to slip through. Without structured processes for change management, rework becomes inevitable.

Misaligned Components

Assemblies that don’t align properly create functional issues, instability, or outright failure. This often happens in multi-team environments where revisions are made without proper coordination.

Lack of File Reuse

Engineers often spend hours searching for existing designs, only to give up and recreate parts from scratch. Not reusing existing parts wastes time and introduces inconsistencies.

Overlapping Geometry

Intersecting or duplicated geometry results in parts that can’t be manufactured or assembled correctly, leading to wasted materials and production delays.

Outdated Hardware/Software

Hardware and software performance limitations, such as slow disk drives, insufficient memory, and sluggish networking, all increase the risk of file corruption and data loss. They also slow productivity.

Data Silos

Disconnected systems prevent teams from accessing or sharing information, increasing the likelihood of duplicated work and outdated files in circulation.

Ways to Resolve Common CAD Errors

Although these issues are common, teams can take proactive steps to minimize errors and strengthen their CAD workflows. Some of the most effective strategies include:

Establish and Enforce CAD Standards

Define clear guidelines for naming conventions, layering, title blocks, and revision practices. Embedding these standards into custom templates ensures every project starts with consistency and reduces miscommunication.

Leverage Automation

Automate repetitive or error-prone tasks like updating title blocks, resizing components, generating BOMs, or exporting file formats. Automation reduces manual effort and prevents common oversights that lead to rework.

Implement PDM or PLM Systems

Product Data Management (PDM) and Product Lifecycle Management (PLM) tools ensure that CAD data is version-controlled, secure, and accessible to the right people. This prevents accidental overwrites, lost data, and confusion about “which file is the latest.” Some PLM systems seamlessly link with CAD software such as PTC Windchill does with Creo.

Invest in Efficient Data Management

Centralized data access, with powerful search and reuse capabilities, prevents teams from recreating work. With streamlined data preparation workflows, engineers can quickly hand off files for simulation, manufacturing, or review without delay.

Upgrade Hardware and Software

Keep both hardware and CAD applications up to date. Modern systems can handle larger, more complex assemblies without the lag that costs valuable hours.

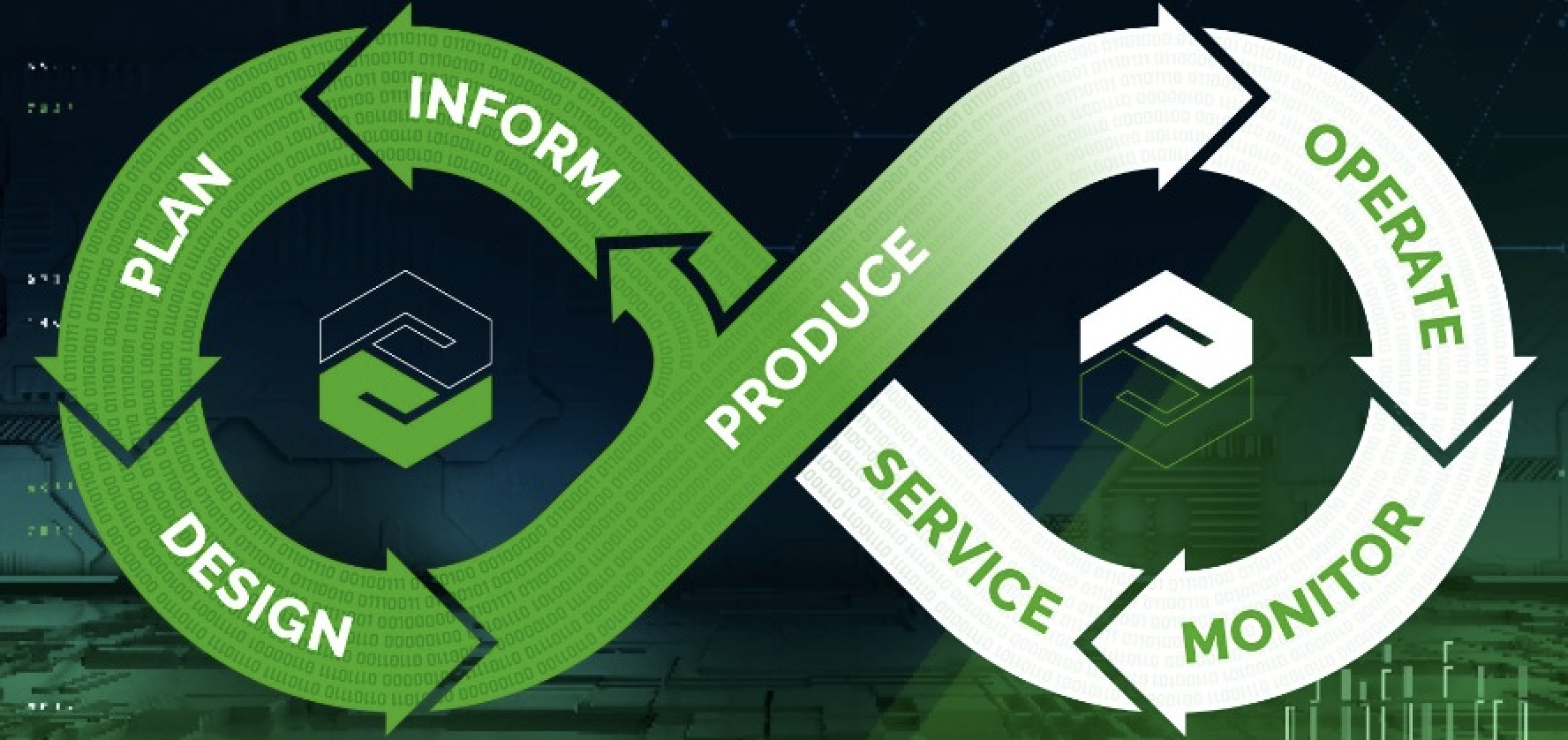

Strengthen Collaboration

Break down silos with integrated systems and connected digital solutions. Real-time collaboration platforms ensure everyone works with the same data, reducing version conflicts and missed updates. Seamless digital threads, such as the one provided by PTC, simplify collaboration.

Enhance User Proficiency

Train your teams on keyboard shortcuts, macros, and advanced CAD features. Skilled users not only complete tasks faster but also make fewer mistakes by leveraging built-in tool intelligence.

Adopt Focused Workflows

Encourage engineers to work on one task at a time rather than multitasking. Focus improves attention to detail, speeds up delivery, and minimizes overlooked errors.`

File Management and Control

Protect design data from accidental deletion or overwriting with robust file access controls. Mature CAD file management practices not only prevent errors but also speed up audits and compliance checks.

By implementing these corrective actions, organizations can dramatically reduce wasted effort, accelerate design cycles, and build higher-quality outputs.

Reducing CAD File Errors with SPK

At SPK and Associates, we specialize in helping engineering organizations streamline CAD workflows. We can help your team implement CAD file management solutions like PTC Windchill PLM and integrated PDM systems such as Solidworks PDM. These solutions ensure your teams gain secure access to controlled data, consistent standards, and automation that eliminates time-consuming manual work. Our team supports you throughout deployment, the training process, and post-deployment. We ensure your engineers work smarter, reduce errors, and deliver higher-quality results faster.

Ready for Fewer CAD Errors and Less Rework?

Errors and rework in CAD are costly setbacks that undermine efficiency and profitability. By addressing common pitfalls, investing in modern tools, and following best practices, organizations can minimize rework. With the right partner, your team can build a robust design ecosystem that accelerates innovation and reduces errors. If you want to ensure your team focuses on creating value rather than correcting mistakes, contact us today.